| Top machining |

APS (Air Plasma Spray), HVOF, Thermal Wire Spray

|

|---|---|

| Other processes |

Polishing, Taping, Grinding, Sandblasting

|

| Operating sectors |

Food, Automotive, Electromechanical, Energy, Hydraulic, Hydroelectric, Plastic processing industry, Industrial machinery, Other sectors...

|

| Work area | 3580 m² |

| Employees | 24 |

| Metals/Materials |

Steels, Special steels

|

| Certifications |

The company provides certifications for all the processes performed.

|

Thermospray SRL operates in the field of “Thermal spray” coatings (HVOF and APS) using the most modern and effective technologies available on the market today. Despite being a young company, it employs a team of collaborators with proven experience in the field of surface finishes and coatings.

The offer of Thermospray SRL covers a wide spectrum of solutions also thanks to the collaboration with Cromostamp Italia srl with which it forms a group.

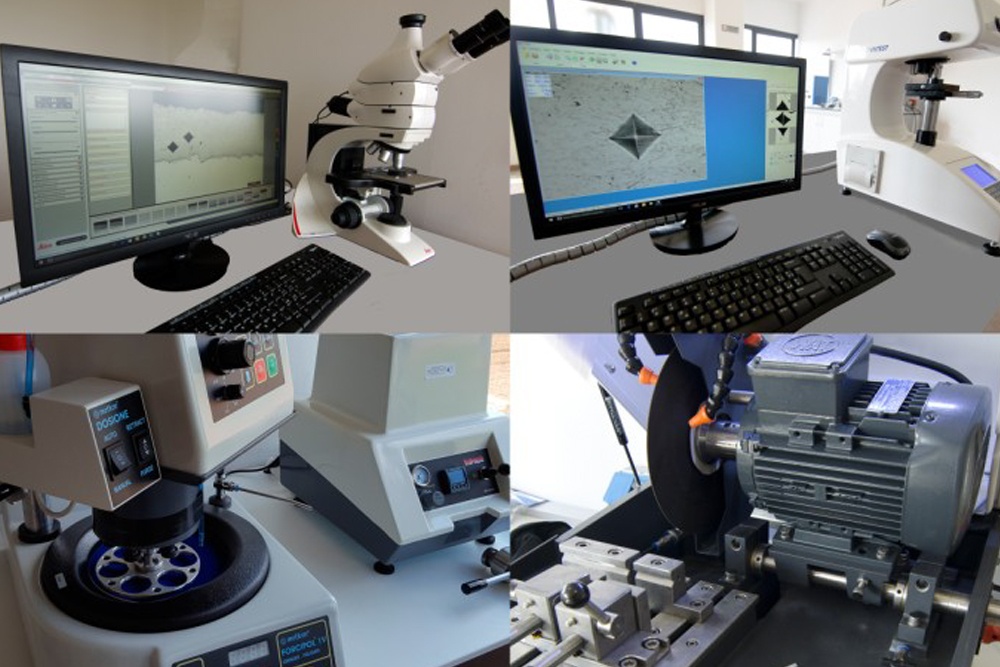

The grinding, taping, polishing and sandblasting services complete the range of mechanical processes aimed at obtaining the surface and dimensional characteristics of the coatings. The internal metallographic laboratory allows us to provide the required certifications on all our products.

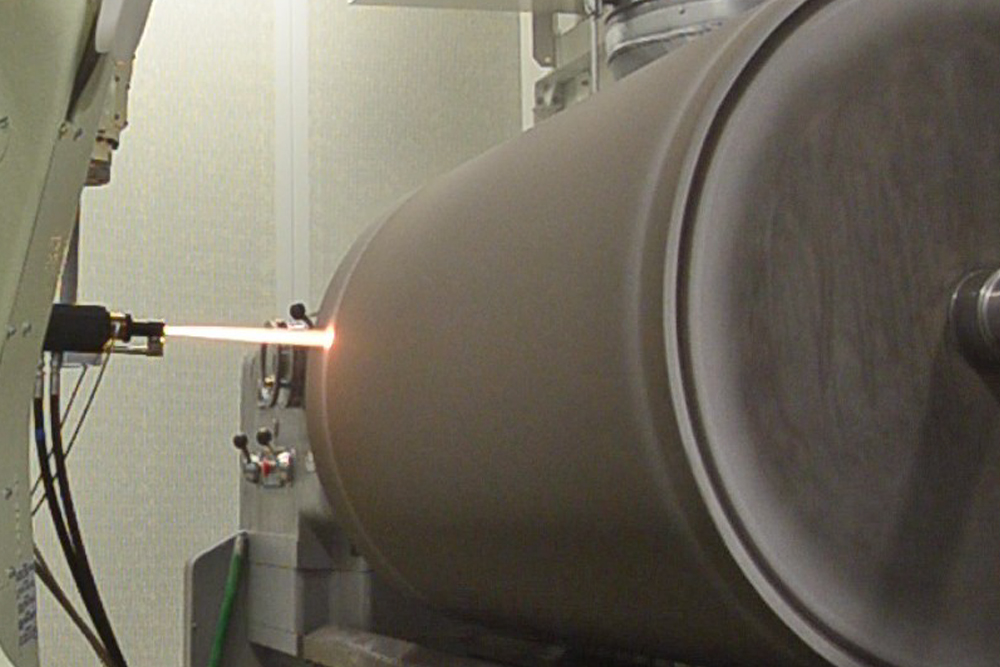

HVOF - High-Velocity Oxygen Fuel

The coatings obtainable using HVOF technology have excellent characteristics including low porosity, high adhesion values, resistance to wear and corrosion, high hardness values and low coefficients of friction.

The wide variety of applicable materials (including pure metals, carbides, steels, self-melting alloys, etc.) and the combinations of these allow to produce a virtually infinite range of coatings with peculiar characteristics according to the requests.

Our systems for HVOF coatings are numerically controlled and regularly calibrated by certified companies.

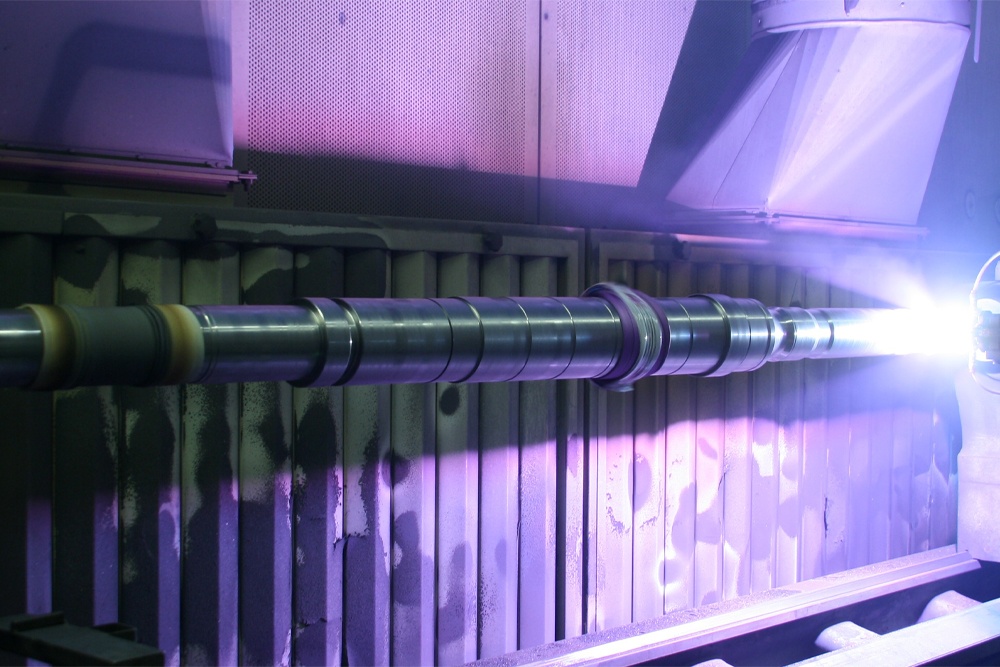

APS

The Air Plasma Spray generated by the ionization of a gas or a mixture of gases, including Argon Nitrogen and Hydrogen, reaches high temperatures (over 16000 ° C) allowing the reduction to the plastic state of ceramics (oxides), abradable materials and metals high fondants.

The use of this technology is more frequent for the production of such coatings which may have, among others, thermal insulation and electrical insulation characteristics.

Our systems for APS coatings are numerically controlled and subjected to regular calibration by certified companies.

THERMAL WIRE SPRAY

It uses metals or metal alloys in wire form as the base material. It is often used for the application of hard coatings for the recovery and dimensional reconstruction of surfaces and is well known for the application of anticorrosive coatings, even on very large structures.

The Air Plasma Spray generated by the ionization of a gas or a mixture of gases, including Argon Nitrogen and Hydrogen, reaches high temperatures (over 16000 ° C) allowing the reduction to the plastic state of ceramics (oxides), abradable materials and high melting metals.

The use of this technology is more frequent for the production of such coatings which may have, among others, thermal insulation and electrical insulation characteristics.

Our systems for APS coatings are numerically controlled and subjected to regular calibration by certified companies.

The coatings obtainable using HVOF technology have excellent characteristics including low porosity, high adhesion values, resistance to wear and corrosion, high hardness values and low coefficients of friction.

The wide variety of applicable materials (including pure metals, carbides, steels, self-melting alloys, etc.) and the combinations of these allow to produce a virtually infinite range of coatings with peculiar characteristics according to the requests.

Our systems for HVOF coatings are numerically controlled and regularly calibrated by certified companies.

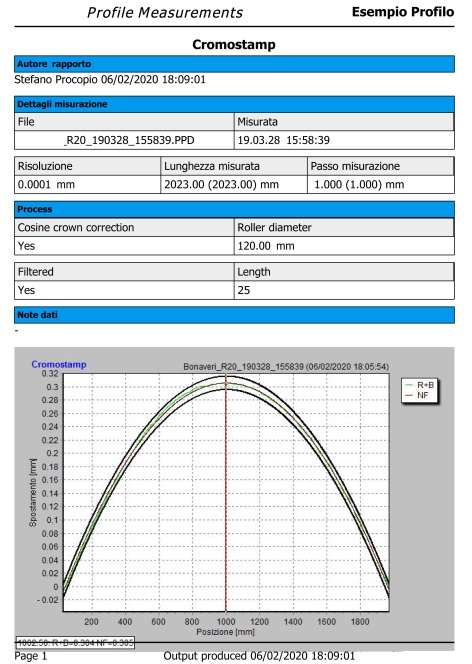

Any required roughness value can be obtained through these operations up to the grindable dimensions and beyond.

Round grinding up to the maximum dimensions of Ø1.200X11.000mm (up to Ø1.500x400mm) and weight 25 tons.

Conical, concave and convex grinding.

It uses metals or metal alloys in wire form as the base material. It is often used for the application of hard coatings for the recovery and dimensional reconstruction of surfaces and is well known for the application of anticorrosive coatings, even on very large structures.

Multi-Process HVOF and Plasma FST MP 50 system

It manages and monitors the supply of components into the spray guns using a fully computerized system. It is composed of a powder feeder, a spray gas distributor using precision flowmeters, a touch screen monitor, a transformation module for feeding the plasma gun, and a management of the safety system which prevents the use of the system if all the parts do not work correctly and if all the foreseen safety measures are not respected. All processing parameters are saved and can be recalled.

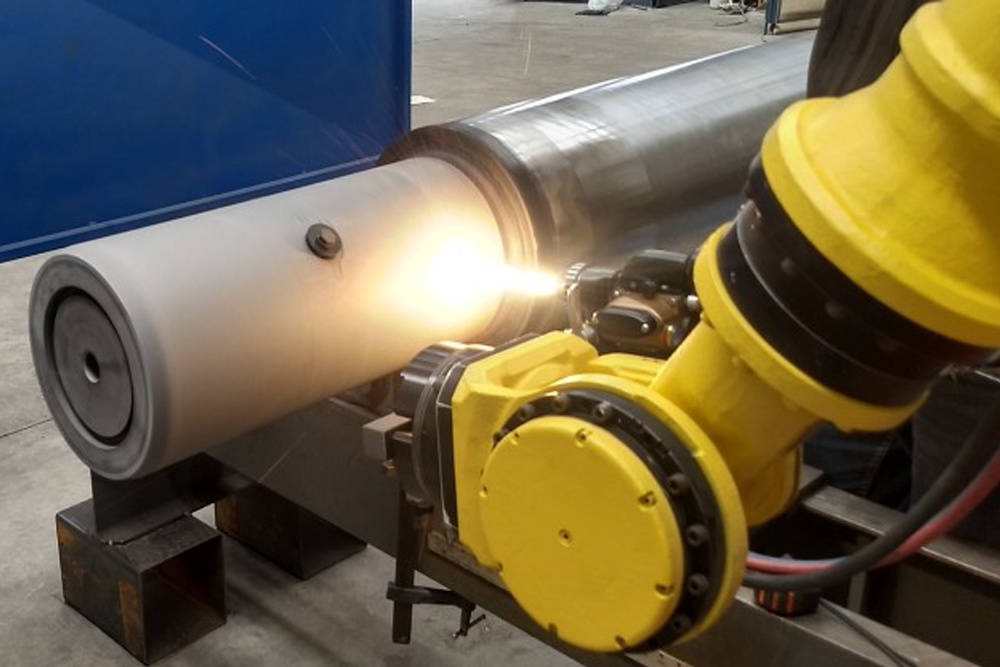

Anthropomorphic robotic arm

Kawasaki robotic arm with 6 controlled axes with a carrying capacity of 165 kg at the wrist with a repeatability of 0.3mm, remote programmable digital control and for self-learning by means of an LCD touch screen panel

Fanuc robotized arm with 7 controlled axes with a wrist load of 165 kg, digital control programmable remotely and for self-learning by means of an LCD touch screen panel used for surface finishes by means of recovery sandblasting, taping and super-finishing by means of diamond abrasive belts.

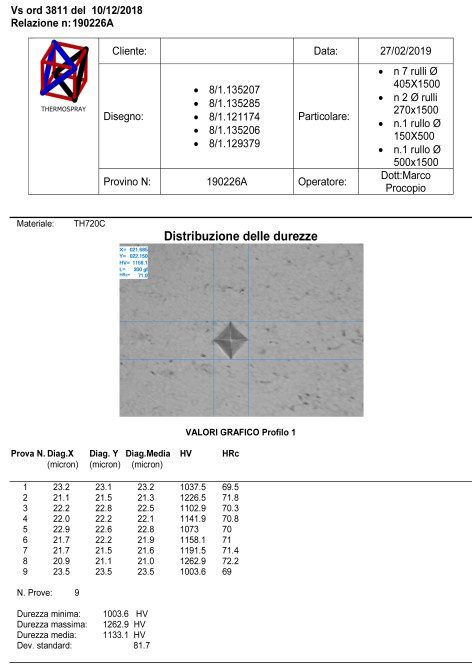

The metallographic laboratory inside Thermospray SRL allows us to provide the required certifications on all our products according to the current legislation on the type of production performed.

We have tools to carry out metallographic analyzes, hardness tests, mechanical tests and shape measurements.

Contact us for more information.

Thermospray SRL provides certifications for all the work performed.