| Top machining |

Milling, Turning

|

|---|---|

| Max turning |

Ø300 x 500

|

| Max milling |

1500 x 700

|

| Other processes |

"done in one" 5-axis multitasking machining

|

| Operating sectors |

Aeronautical, Aerospace, Electrical-electronic, Photographic, Medical, Packaging, Racing, Other sectors...

|

| Production area | 700 m² |

| Employees | 6 |

| Metals/Materials |

Steel, special steel, aluminum, aluminum alloys, bronze, iron, brass, copper, titanium, special metals, all polymers

|

| Favorite lots |

Small series, periodic series

|

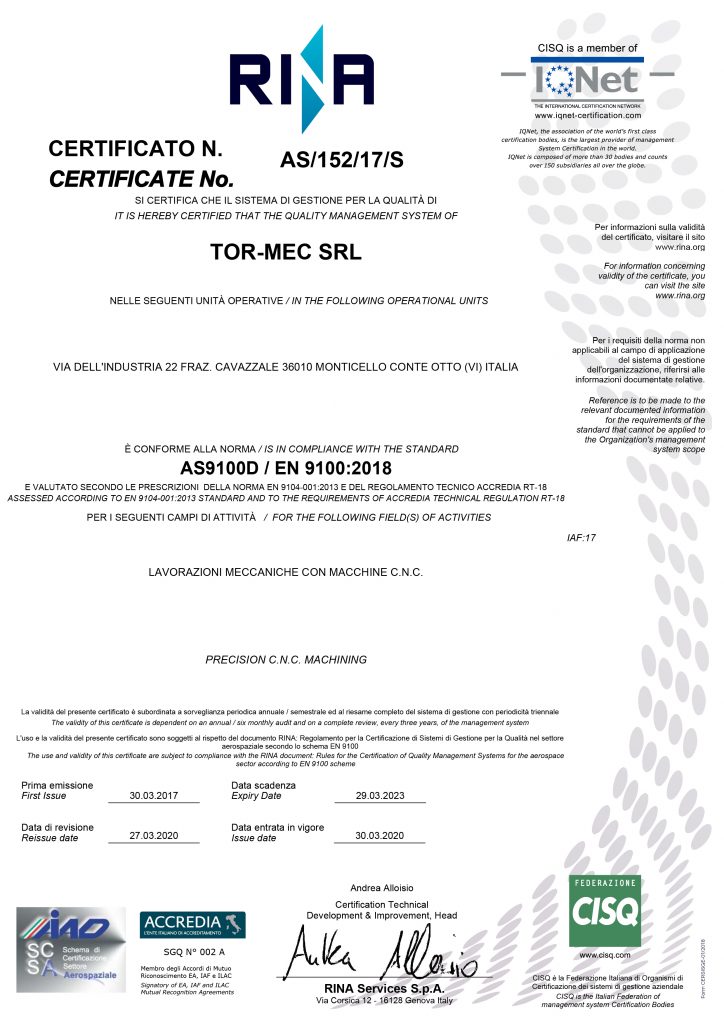

| Certifications |

9001:2015pm - 9100:2018pm - 45001:2018pm

|

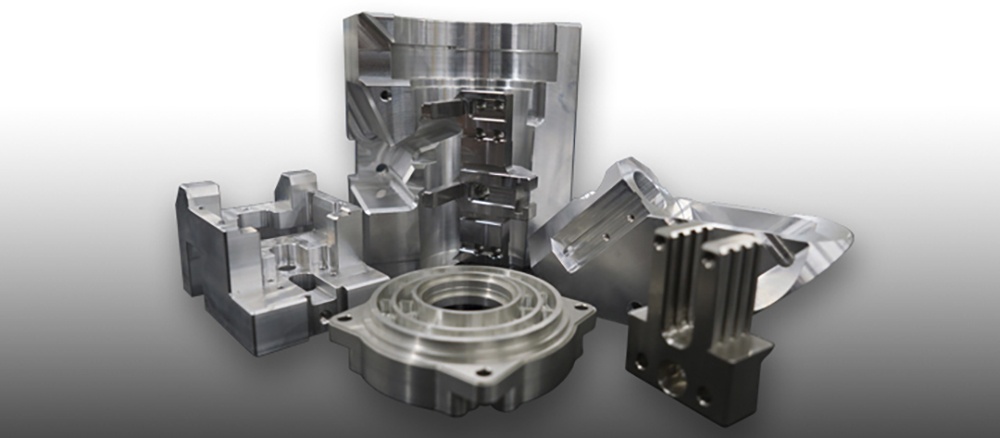

In THOR-MECH we do our best when we receive requests small-medium orders, of size Max 300 × 500 di diameter o 1500 × 700, to high technological content.

Thanks to the presence of multitasking work centers, we can create and deliver from 20 to 1000 pieces per month, managing to be competitive in the market of interest.

Founded in September 1978, with the name of TOR-MEC di Bianchi Luciano, the company proposes itself to the market as a manufacturer of special mechanical parts and small mechanical equipment.

Today the company presents itself to the market as THOR-MECH and has a highly qualified staff and a fleet of high-tech machines and software to meet the customer's needs, from the construction of the prototype to the production of the requested part.

Production

Industrial Automation

Multi-axis machining

Prototypes

THOR-MECH specializes in multi-axis CNC mechanical machining. From the design to the creation of the requested part, we make sure to monitor every process, so that the component created reflects the quality standards and complies with the customer's requests.

Welcoming the challenge of the contemporary market, we decided to support traditional instrumentation centers of multitasking milling, indispensable for machining pieces with more complex geometries.

We can accomplish mechanical components di small e medium size with high technological content, intended for different sectors. Our turning operations are performed with CNC machine tools, multitasking work centers and traditional chip removal machines, following certified procedures.

In addition to the turning or milling of high-tech components, we also take care of making engravings on the pieces made, based on the project specifications.

THE COMPANY

Today the company offers itself to the market with a highly qualified staff and a fleet of high-tech machines and software to meet the customer's needs, from the construction of the prototype to the production of the requested part.

All our service is based on machining performed with CNC and traditional chip removal machine tools, following certified procedures.

Look at the machinery list

Assigning and managing workloads, monitoring progress and delivery dates, having precise control of suppliers of materials and treatments is a necessary requirement to be a reliable partner.

We have CMMs / ALTIMETERS / PROJECTOR / ROUGHNESS GAUGE / MICROMETERS available to carry out careful quality control on the pieces made.

THOR-MECH has the following certifications: