| Top machining |

Laser cutting, blanking, milling, welding, robotic welding, bending

|

|---|---|

| MAX. milling |

1000x2000x500 mm

|

| Other processes |

Mold construction, Wire EDM, Marking, Grinding, Blanking, Brushing, Deburring

|

| Services |

Prototyping, Carpentry, Assembly, Mold construction, Testing, Technical drawing, Mold design, Rapid prototyping, Prototypes, Co-design

|

| Operating sectors |

Automotive, Elevators, Lighting, Design, Electromechanical, Boiler production, Food, Ventilation, Furnishings, Construction, Electrical - Electronic, Energy, Other sectors...

|

| Production area | 4500 m² |

| Employees | 50 |

| Metals/Materials |

All types of metal and all thermoplastic materials (Steels, Special Steels, Aluminium, Aluminum Alloys, Bronze, Iron, Brass, Copper, etc) |

| Favorite lots |

Periodic series, Large batches, Small series or limit series, Pre-series prototyping

|

| Certifications |

UNI EN ISO 9001: 2015

|

For over fifty years Terenzi Srl has been designing, producing and assembling components or finished products, whether technical or designer, using molds or laser cutting, punching (including combined cycle), bending and processes typical of precision light carpentry. The molds for blanking, drawing and injection of thermoplastics are made by the internal tool shop.

We take care of all phases of product industrialization: from design or engineering to production and final assembly. We take care of every detail with precision, quality and competence, paying attention to aesthetics and the environment. Our products are 100% Italian and over time we have gained great experience in the processing of metals and plastic materials.

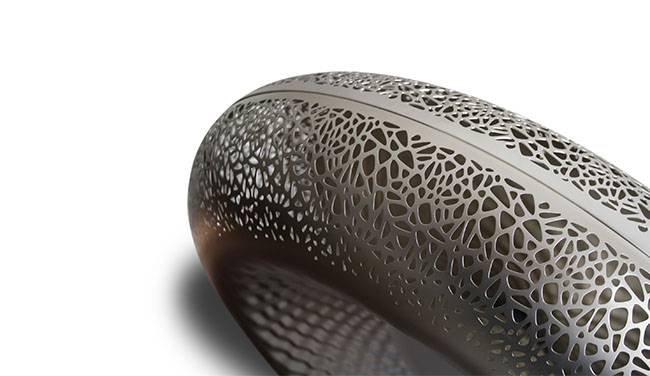

Pendant lamp body in anodized aluminium

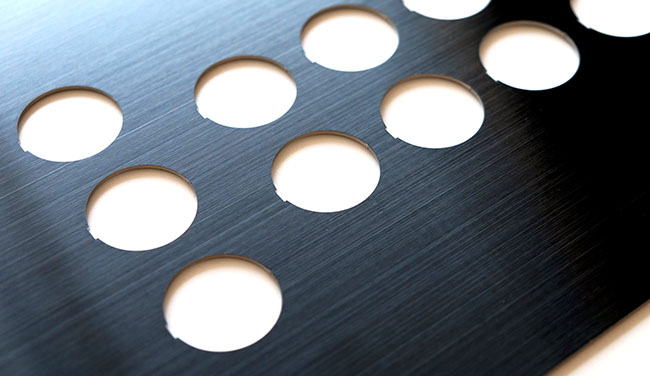

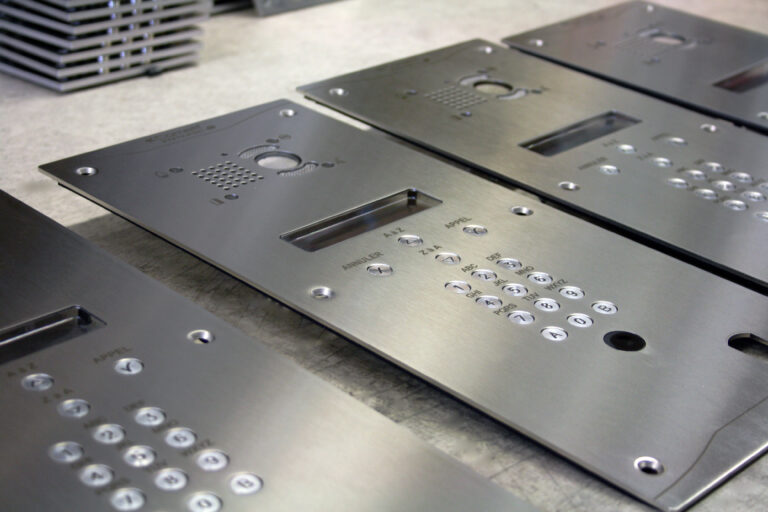

Front panel for elevator pushbutton panel in steel

Stainless steel espresso machine front

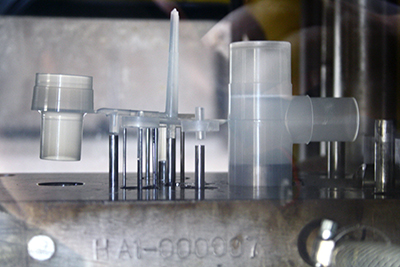

Lighting element in plastic material

Green disc in recyclable ecological plastic material

Aluminum bulb cover

Case for electronics, stainless steel meter counters

Automotive battery case plastic overmolding on metal

Steel electromechanical valve bush

Copper boiler components

Stainless steel analogue intercom front panel

Stainless steel boiler component

Cold rolled electric broom semi-cassette

Front panel for elevator button panel in steel

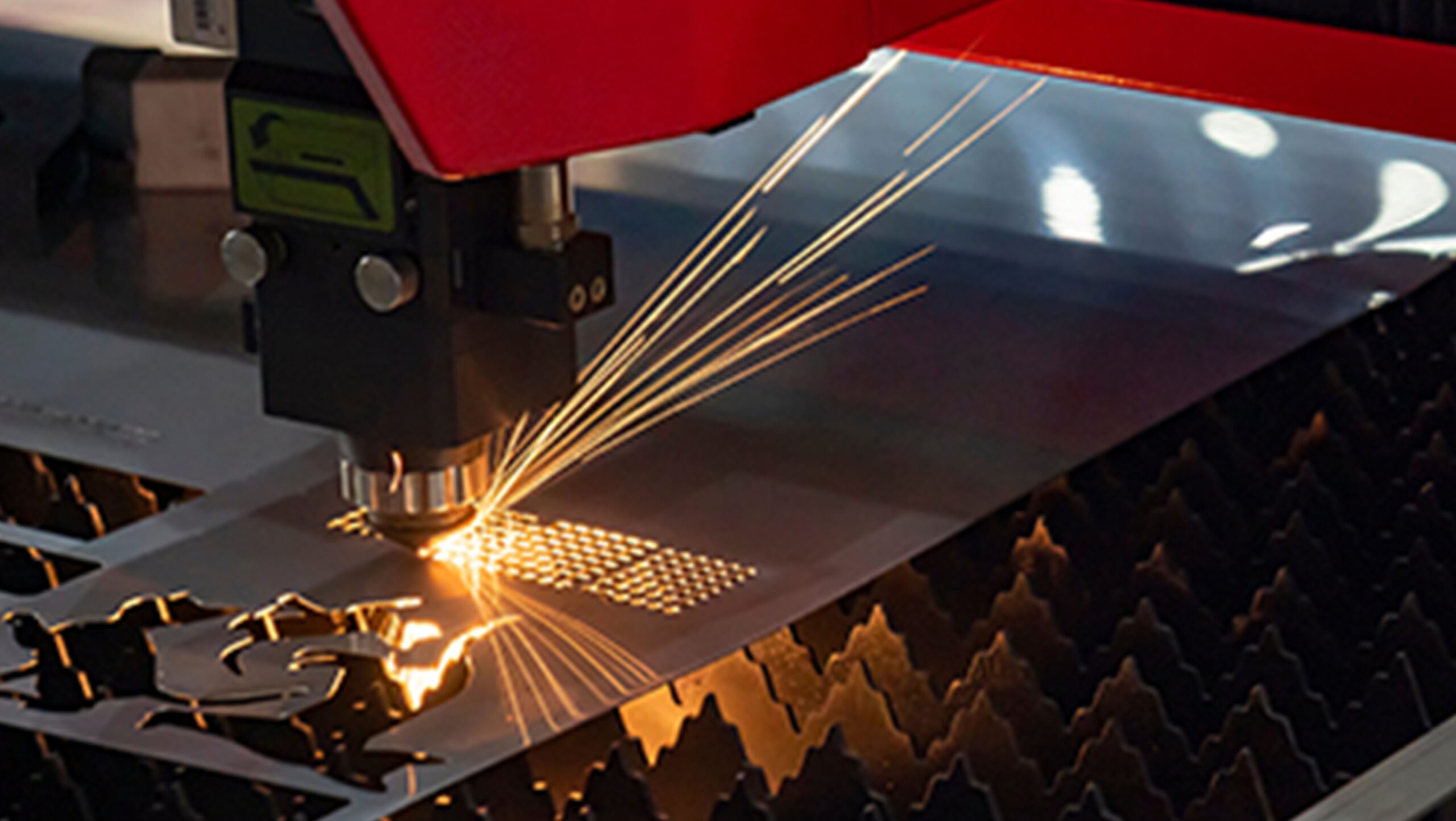

By means of high-tech laser cutting lines, CO2 and fibre, with cutting power of 2000 watts and a working range of 1500x3000 mm, prototypes, samples and pre-series can be created in a very short time and at low costs. Furthermore, thanks to the loading and unloading robots, it is possible to carry out large productions without having to build moulds.

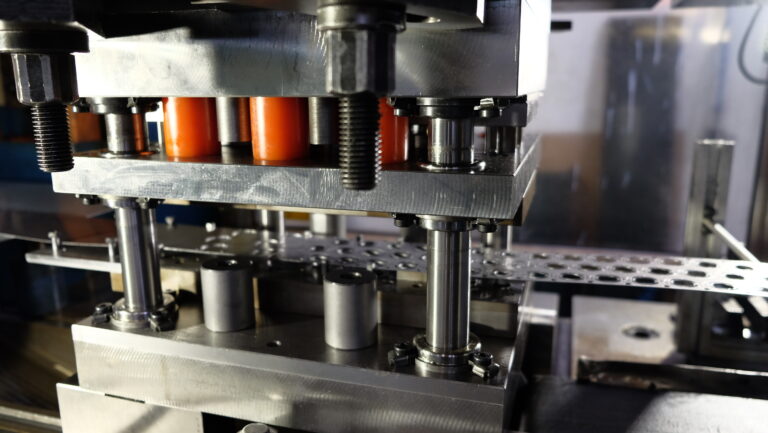

We carry out shearing operations using a complex, step and transfer shearing iron made by our tool shop, which involves a gradual deformation of the piece until the finished product is obtained.

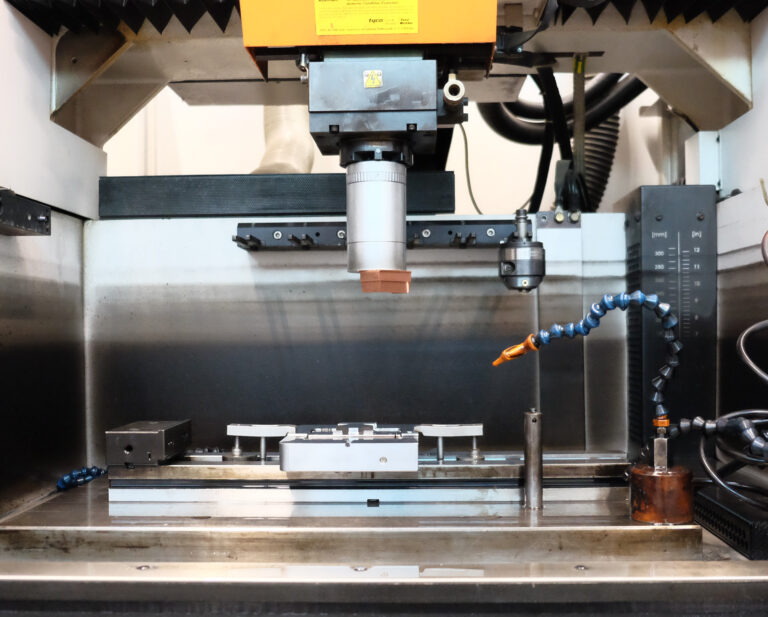

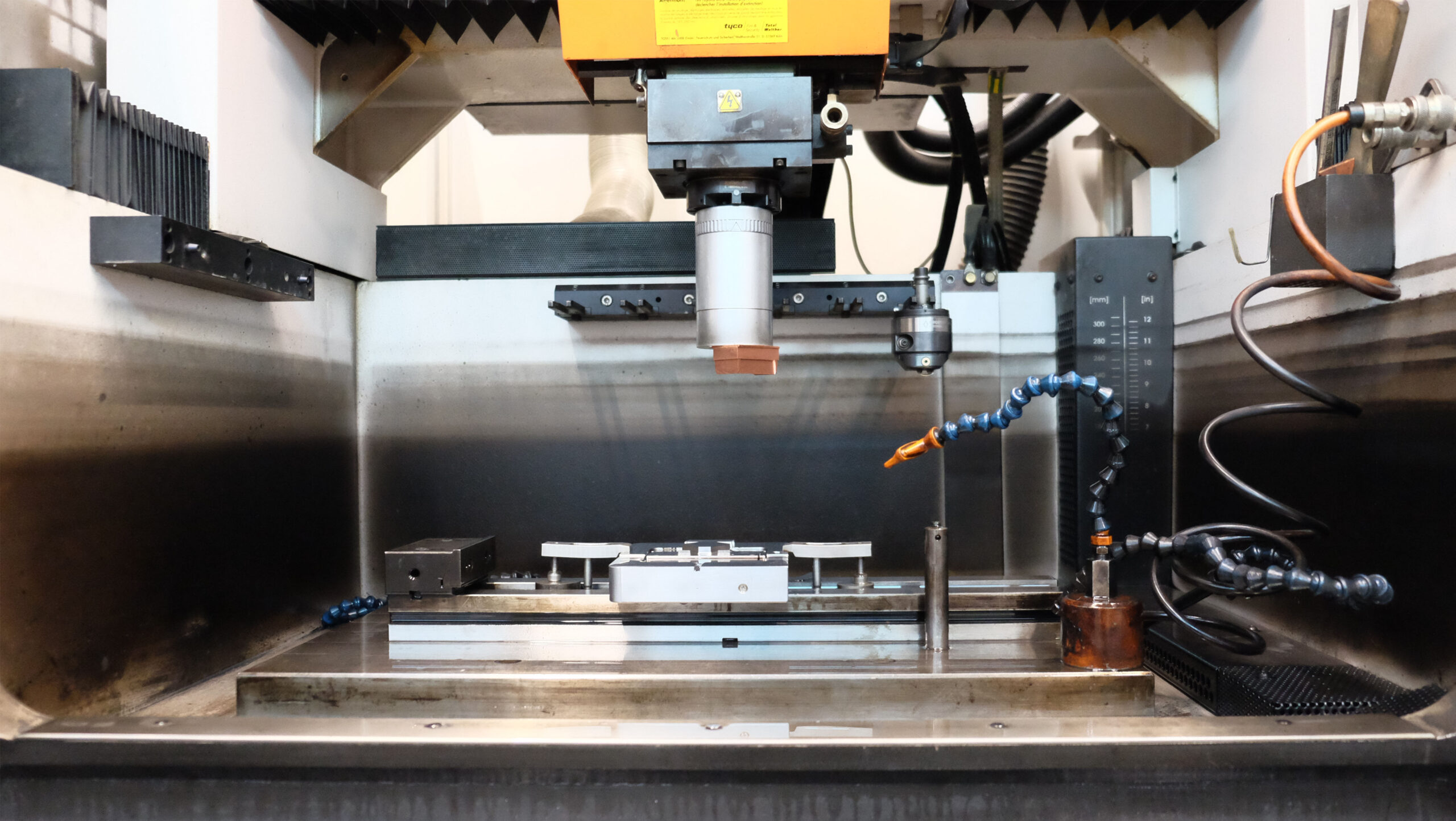

The machine park includes high-speed machining centers for the processing of hardened materials and high-power machinery for large-sized processes (1.000×2.000×500 mm).

The 130 ton press brakes, with a 3000 mm work surface, represent one of the latest technological innovations in the sector, as they are equipped with three-dimensional numerical control for the automatic management of the bending cycle and the verification of interference.

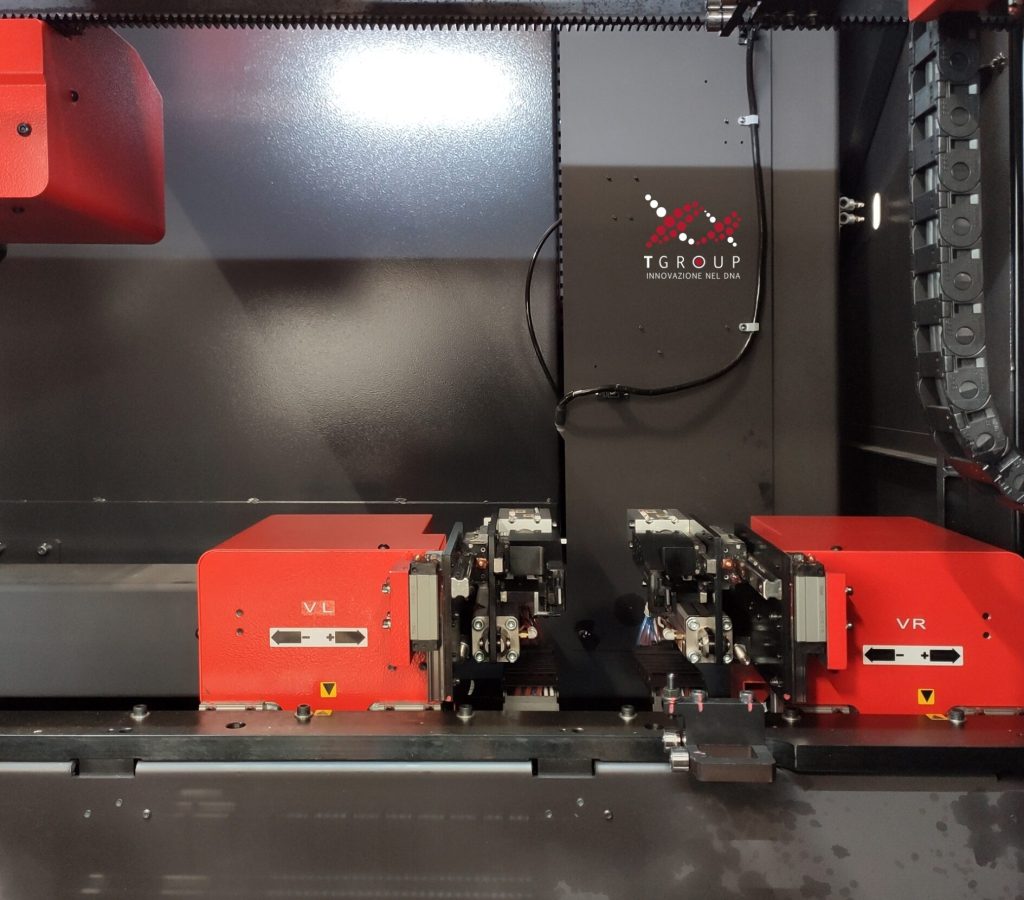

We also boast a latest generation machine, equipped with automatic tooling.

We perform:

The department dedicated to these operations was created with a concept of multifunctionality: in fact, numerous pallet areas have been provided for the management of a large and varied warehouse of semi-finished products, a suspended system has been created for the branching of services which allows high flexibility of work islands.

From an initial trance workshop, Terenzi evolves. The design and tooling unit is added for the design and production of molds for metal processing (return, progressive and transfer moulds) and for plastic moulding.

With the importation from the USA of one of the first wire EDM machines with numerical control, the company expands and progressively integrates new services and processes.

Our machine park has stations dedicated to wire EDM (WEDM) and die-sinking (EDM) machining with automatic electrode change.

Terenzi presents itself as a center of expertise, also offering superficial treatments of:

WHY CHOOSE US?

The careful evaluation of all aspects of the orders, the constant updating of skills, the renewal of applied technologies and the careful selection of raw materials, allow the processes to be innovative, dynamic and optimised, reaching high quality standards, also attentive to the theme of environmental sustainability and the future of the planet.

OUR DATA

The co-design, engineering, mold design and automation activities are carried out by the technical office using 3-axis cad-cam software and specific applications for the study and simulation of production cycles. To ensure maximum flexibility, the design stations are able to directly import files generated by various CAD applications. The entire technical department is managed and monitored with a software for scheduling and accounting of orders, accessible via the web also by customers, to check the progress.

Our areas of expertise are 8, to make production processes more fluid and also offer integrated services:

TOOLING: Die-sinking EDM for mold manufacturing

TOOLING: 3D milling for molds

TOOLING: Automatic cutter for molds

CARPENTRY: Automatic bending machine

CARPENTRY: Fiber laser cutting

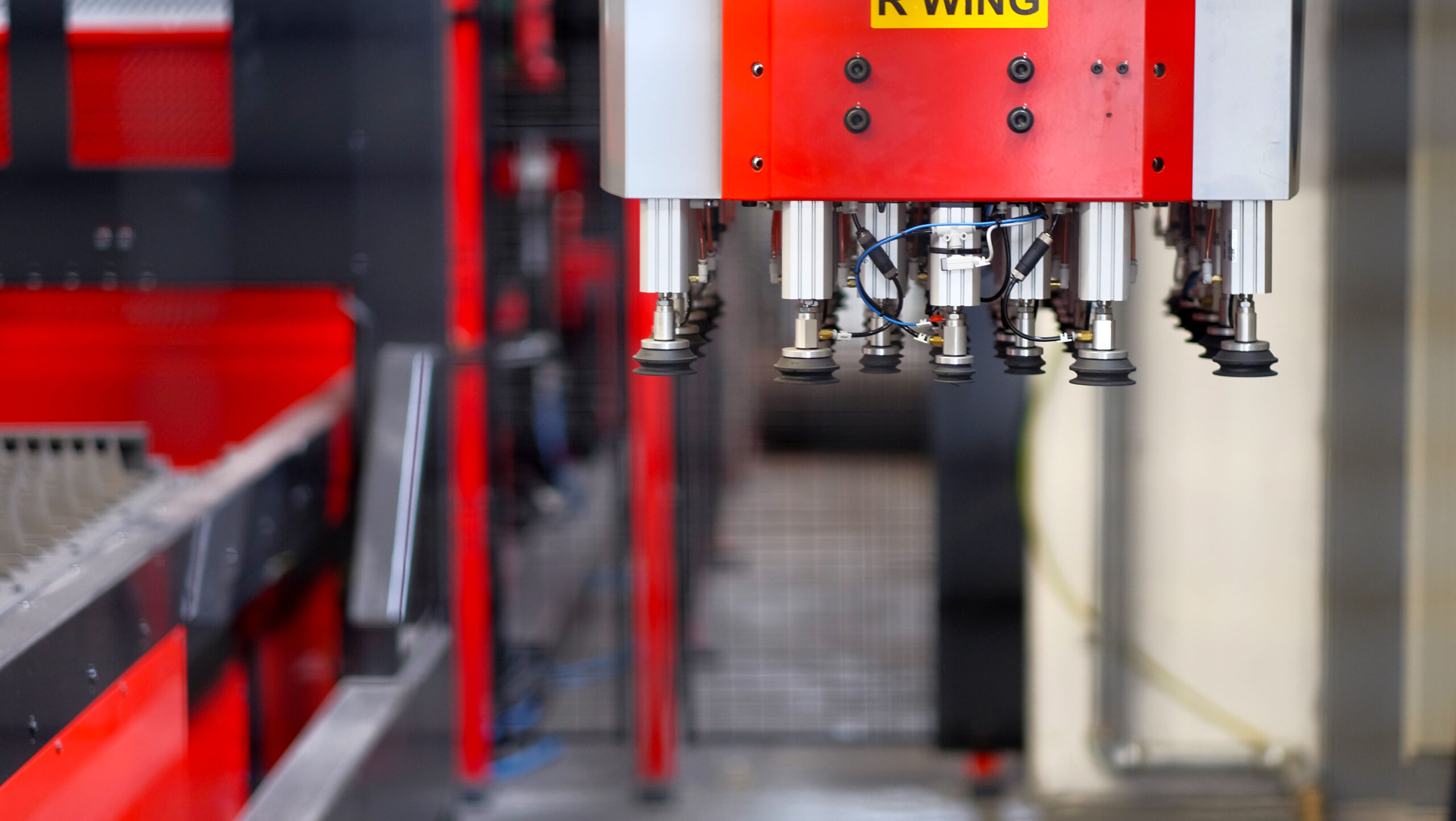

CARPENTRY: Fiber laser cutting / Automatic sheet movement

CARPENTRY: Combined technology: cut and punched stainless steel sheet

CARPENTRY: Combined technology

CARPENTRY: Satin finishing

PLASTIC MOLDING: Injection press

PLASTIC MOLDING: UV printer

SHEARING MACHINE: Fiber laser with plate picking automation

SHEARING: Shearing press with 8-station transfer mould

We monitor waste and seek continuous improvement by verifying production times and methods.

We also take care of the daily monitoring of ongoing productions with dimensional surveys and checks relating to aesthetics.

Terenzi Srl has obtained UNI EN ISO 9001:2015 certification for the design and construction of molds and equipment for metal and plastic, molding of plastic parts, shearing, drawing, bending and cutting of metal parts, assembly of semi-finished mechanical products for third parties .

On 10.06.2021 we received an important award for our company, for all of us at Terenzi Srl – TGroup.

With tenacity, in the midst of the Covid19 pandemic, we reconverted our thermoplastic molding department, producing in a very short time "Safe Breath“, a mask to help the country, reusable, non-disposable to protect the environment, CE certified as a medical device.

At the Terenzi Srl headquarters in San Giuliano, photovoltaic panels have been installed in 2 systems, on the roof of the company's Block 3. Approximately 2000 m² of panels, for a total of 300 kW.

The energy needs that these panels cover can reach up to 70% of the annual energy needed, absorbing solar energy; therefore not all the energy is produced internally, but the majority, and the remainder is purchased by the Terenzi group to cover the total requirement.

Terenzi deals with the ecogreen production of recyclable plastic music records, free of harmful PVC and free of CO emissions2.

The objective is to create a real virtuous circle. We start from the raw material, which is recycled, to create a disc with low environmental impact with processes of proven excellence among those currently known and available.