| Top machining |

Turning, Milling, Production of dissipation systems, Extrusion technology, Heat Sink Technology, Cold Plate Technology, High power heat sinks, Electronic components, Prototyping, Assembly, Boring, Laser cutting

|

|---|---|

| MAX. turning |

Ø 700

|

| MAX. milling |

5000 mm

|

| Services |

Testing, Technical Drawing, 3D CAD & CAM Design, Rapid Prototyping, Prototypes, Replication of advanced parts, Dimensional surveys

|

| Other Processes |

Surface treatments, anodizing, burnishing, tumbling, chrome plating, lapping, polishing, marking, sandblasting, galvanizing, extrusion, oxidation, painting

|

| Operating sectors |

Aeronautical, Aerospace, Agricultural, Urban furniture, Astronomical, Equipment, Power electronics, Military, Mobility, Renewable energy, Other sectors...

|

| Work area | 6000 m² |

| Employees | 70 |

| Metals/Materials |

Steels, Special Steels, Aluminium, Aluminum Alloys, Iron, Brass, Copper, Special Metals

|

| Favorite lots |

Large lots, periodic series

|

| Certifications |

Certificates: IATF 16949, ISO 9001, ISO 14000

|

MG ITALY is your ideal partner. The facility is built to provide large and repeated production batches over time.

With a machine park made up of over 15 high-level machining centres, MG offers itself as a prime contractor for carrying out mechanical processes based on customer designs, guaranteeing the production of extremely high precision parts with limited times and costs.

MG Italy Srl deals with the production of high quality electromechanical components and precision machining. The company focus is to establish a solid and recognized presence worldwide. The forty-year history of the MG group has allowed it to develop considerable know-how in technical thermals.

MG Italy Srl boasts the production of highly efficient performance parts. Our organization is involved in different sectors: Continuous facades, Furniture, Transport, Cooling company, Automotive, Electronics, Civil and Military Defence, Design Lighting, Engines, Aerospace, Dissipation, many others.

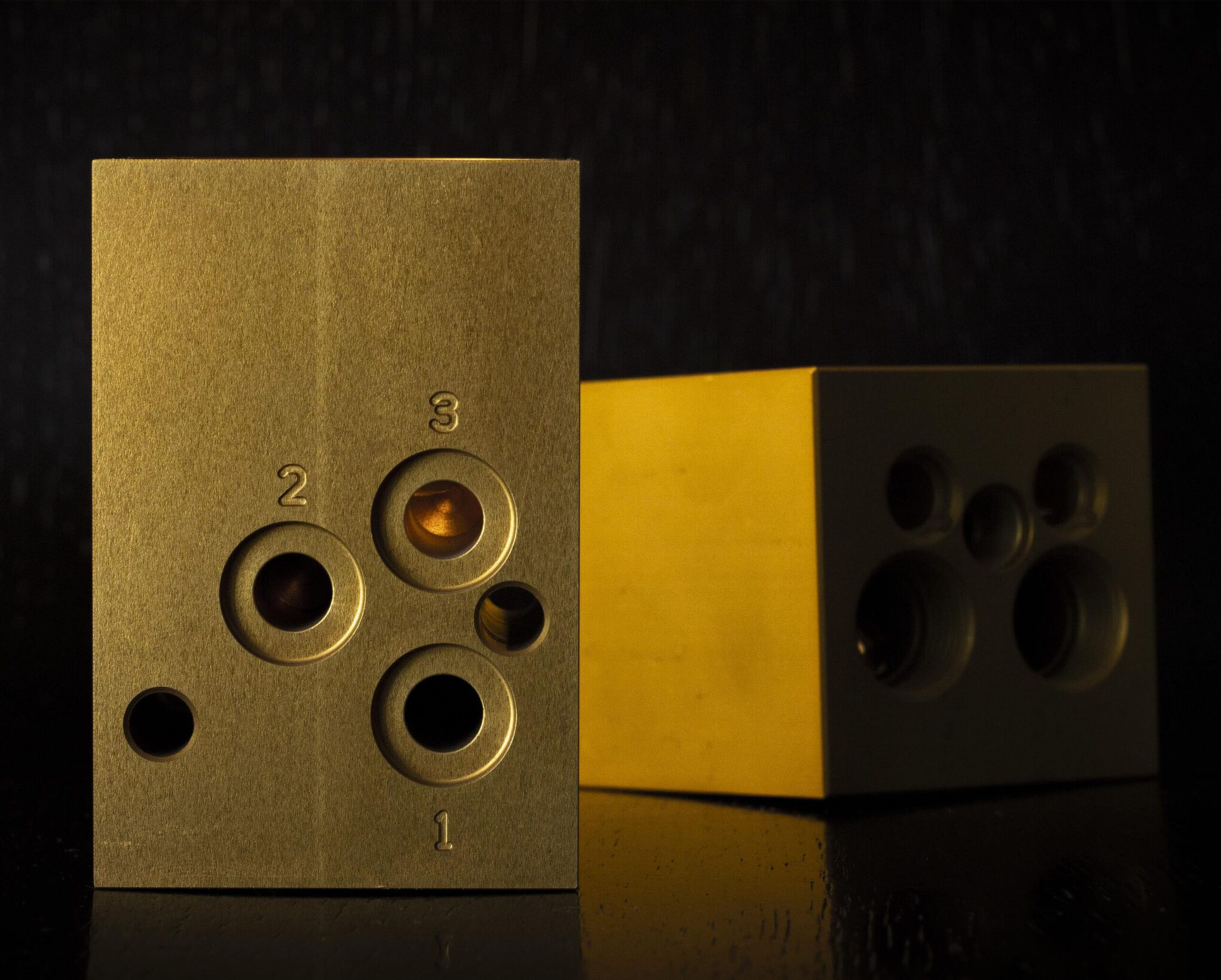

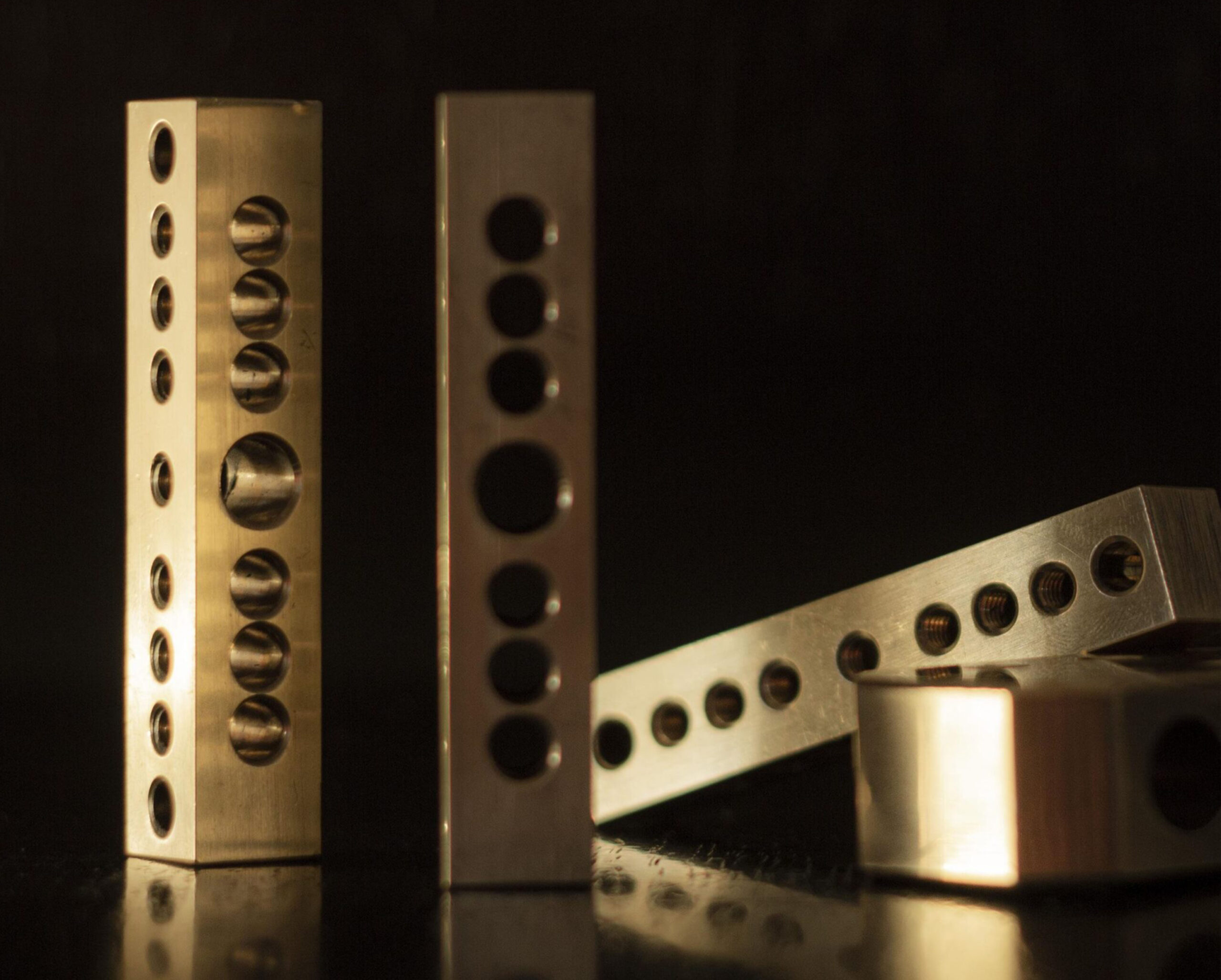

Hydraulic systems

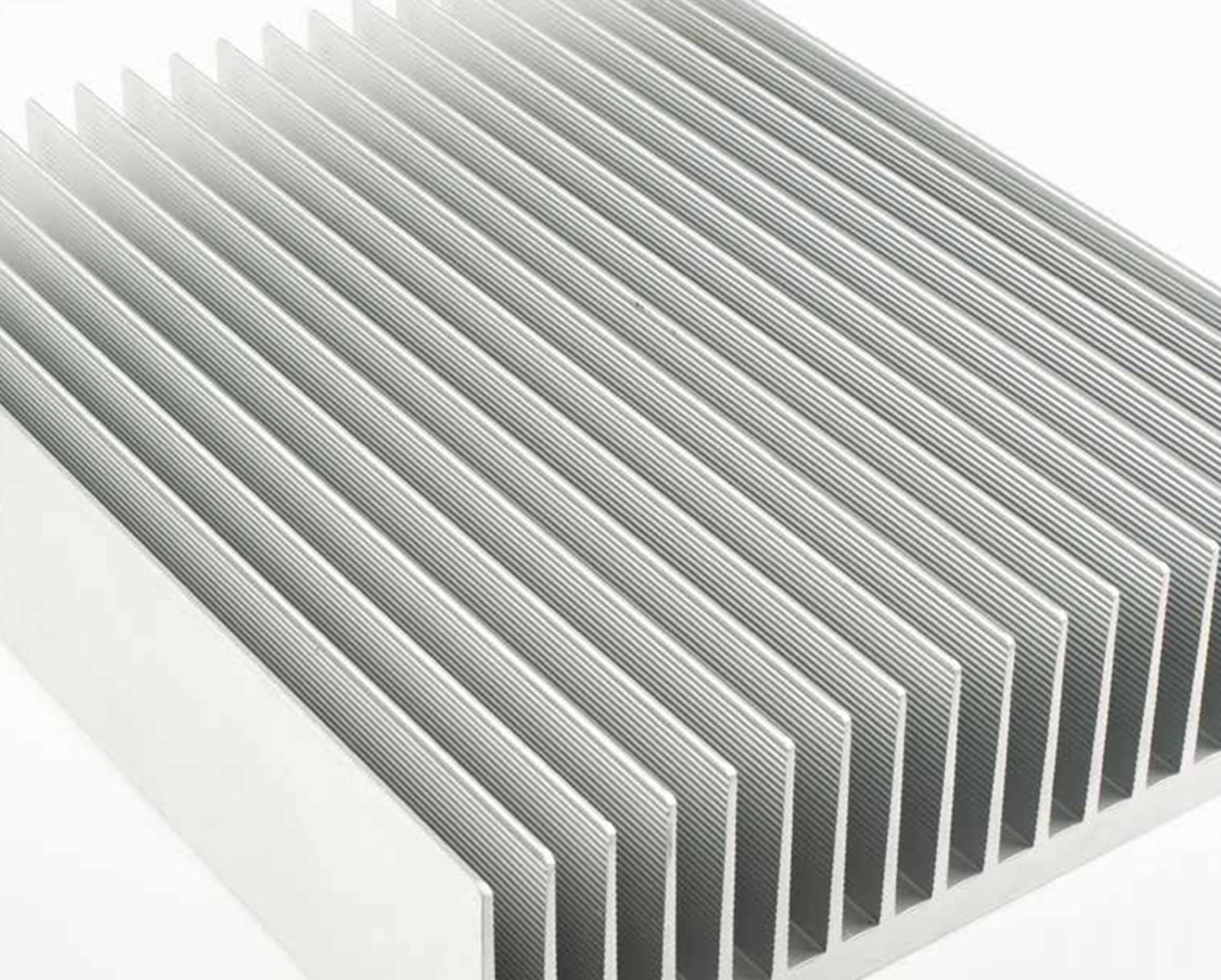

Extrusion cooling systems for electronics

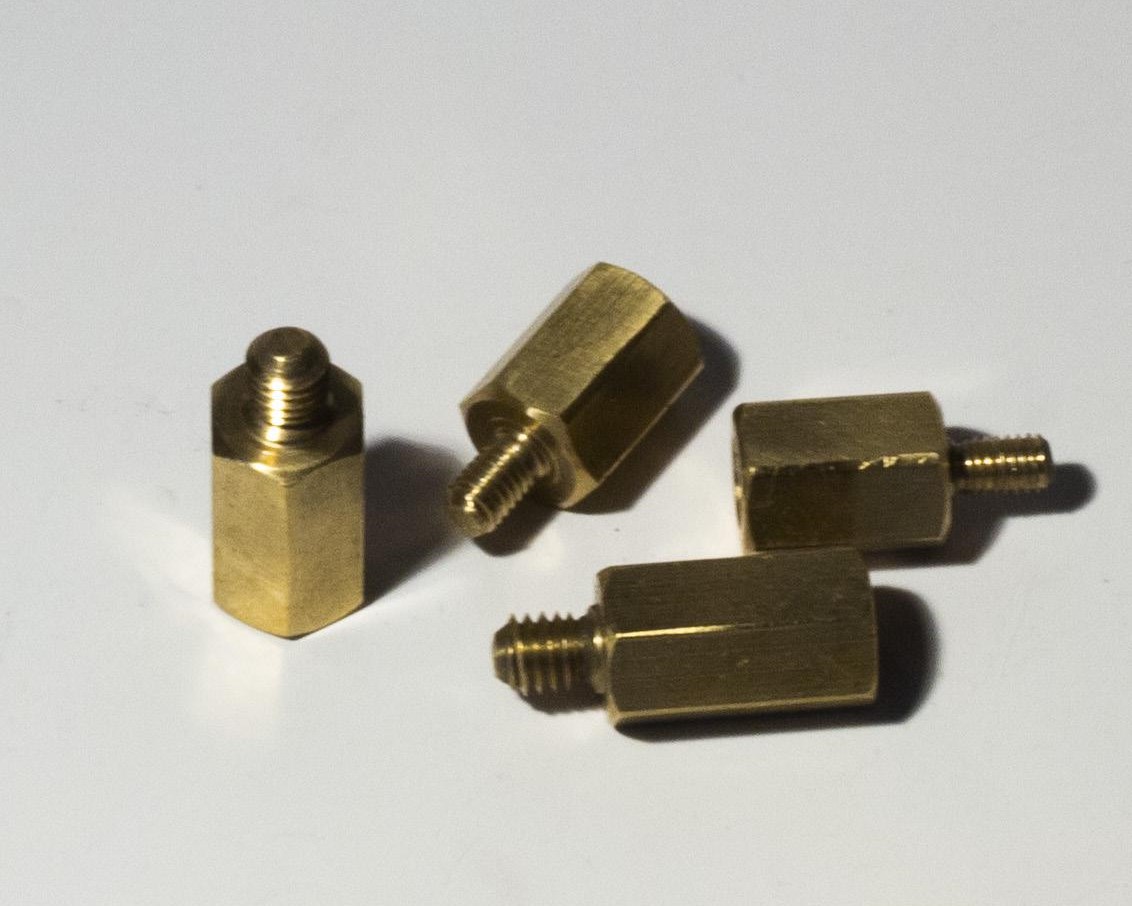

Turned parts for the avionics sector

Turned parts for the furniture sector

Detail milled with 5 axes for the military sector

Turned part for the electronics sector

High power cooling system with heat sink technology

Copper connections and flexible bars

Milled detail in plastic for the medical sector

MG ITALY has cutting-edge machines for CNC turning, including 10 CNC lathes, equipped with motorized tools with C axis and Y axis, with working fields up to diameter 600 with bar passage d.116 mm, for a turning length of up to 1200 mm, also served by bar loaders, lunettes and tailstocks in cycle.

With a machine park made up of over 20 high-level machining centres, MG offers itself as a prime contractor for carrying out mechanical milling operations to customer designs, guaranteeing the production of extremely high precision parts with limited times and costs.

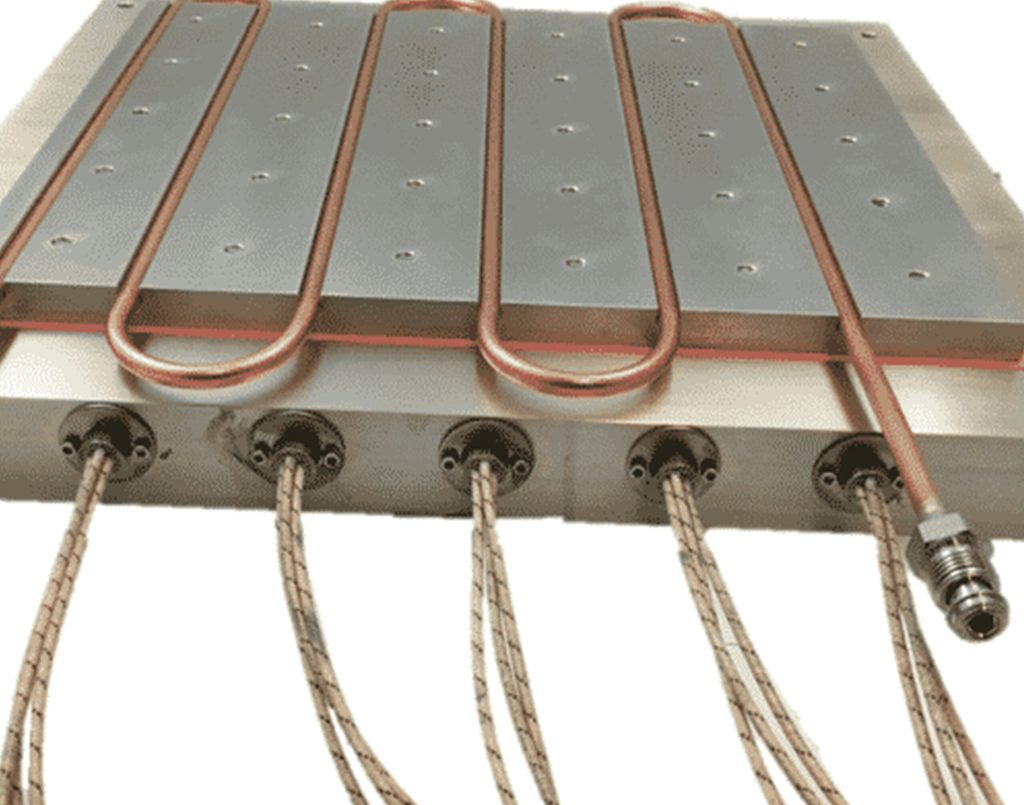

MG develops and produces heat dissipation systems with different technologies, air, liquid, and many others. We are one of the leading companies in the world in the production of aluminum heat sinks.

Our main activities include study, design and development of profiles aimed at creating finished products with the possibility of using different technologies that allow improving dissipation efficiency.

Extruded products are generally used in medium power systems in both natural and forced convection.

The extruded technology products are presented divided by shape (T, H, L, K, E, U, P), width and height, and organized in ascending order of size.

Totally innovative product lines with completely custom heat sinks and, at the same time, with all the features of a standard solution.

Made through the mechanical assembly of the base and fins, or in a monolithic version with the use of exclusive and patented Ultra Heat and Heat Plus technologies, they guarantee superior thermal performance and mechanical characteristics of absolute excellence, ensuring an average decrease in thermal resistance between 7 and 10%.

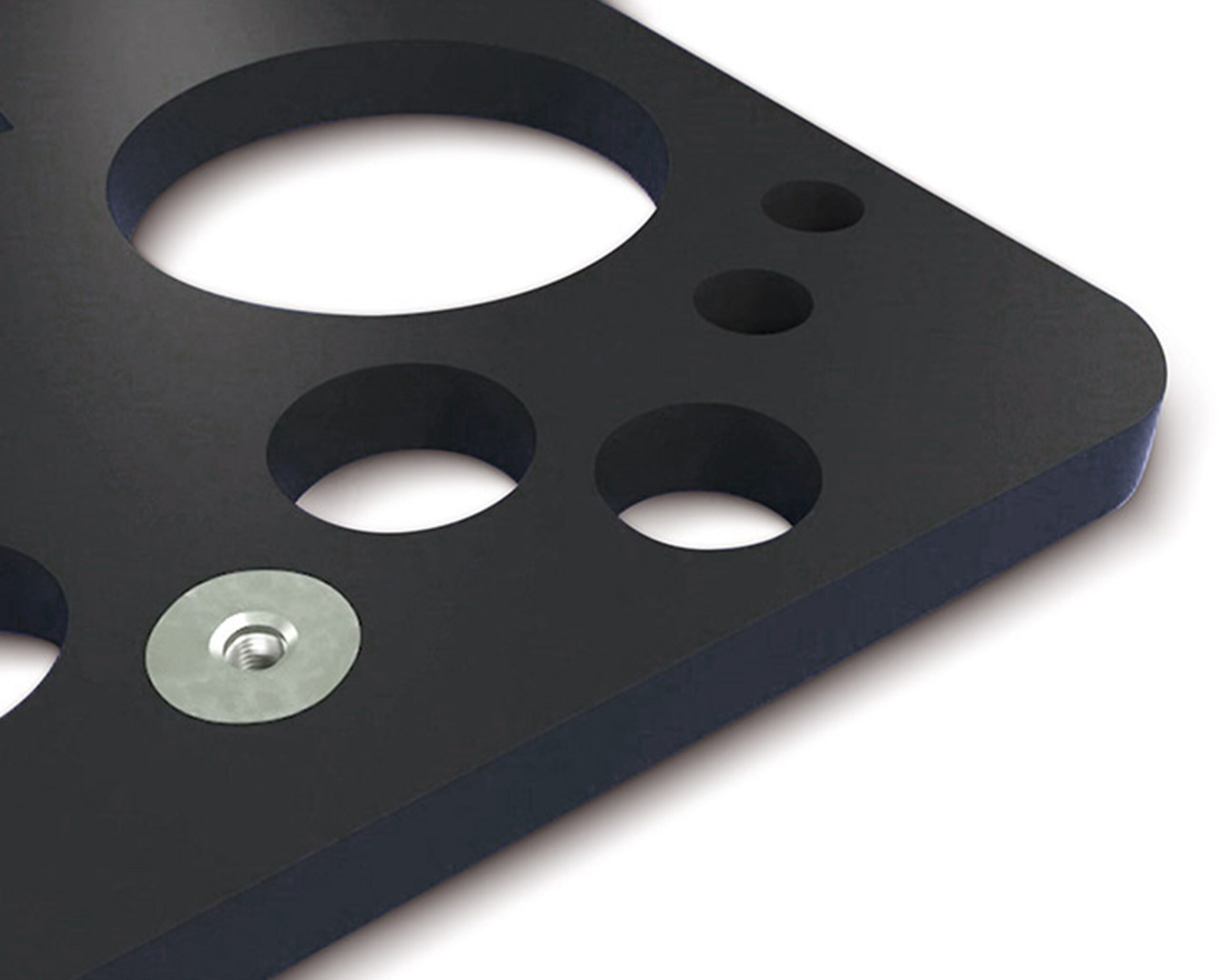

COLD PLATE technology is optimal for efficiently managing complex systems with

high concentrated powers.

This system allows you to avoid noise and problems due to vibrations, considering that

this dissipation system can also be used in dusty environments where it is not possible to use forced air.

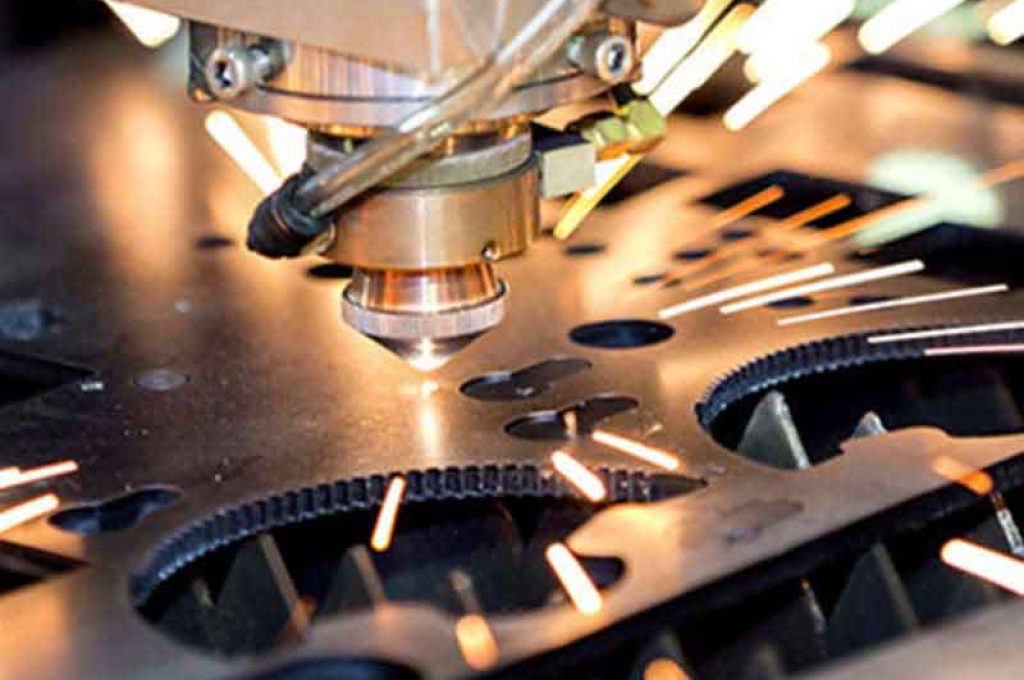

MG ITALY boasts long experience in sheet metal laser cutting, we work sheets with maximum dimensions of 4040 x 2000 mm. The targets that the company addresses for sheet metal laser cutting are companies in the agricultural, food, furniture, automotive, chemical, construction, earthmoving, household appliances and oil sectors.

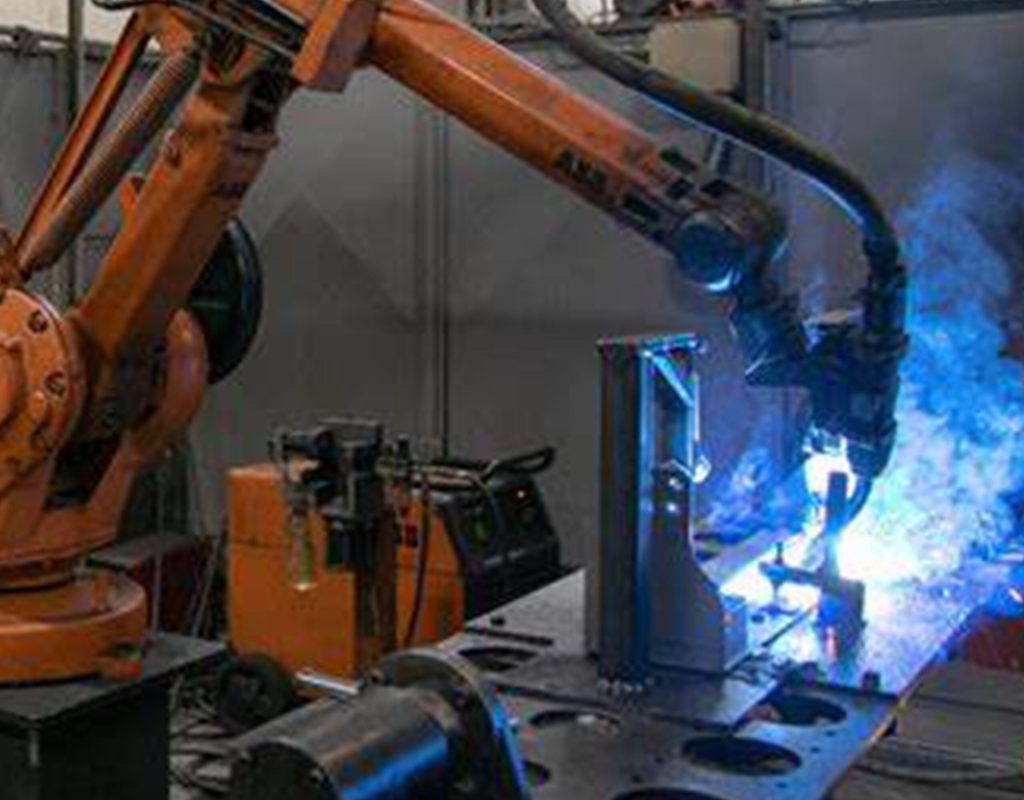

MG ITALY is specialized in the creation, assembly and assembly of groups for industrial plants and machinery. We carry out assembly of groups of equipment internally, following the specific requests, guaranteeing care, attention and quality that our major customers recognize in us after years of collaboration.

The company also has a well-equipped metal welding department, capable of successfully tackling any type of work.

The specialized staff deals with both the welding of metal parts and general welding for third parties, operating with great precision and efficiency.

Chrome plating is the industrial process of coating a metal article with a layer of chromium, a steel-grey metal with a characteristic hardness and resistance to corrosion.

Chrome plating is undoubtedly, among all the most used in galvanic processing, the process that has undergone the least changes since it entered industrial practice around 1920.

The galvanizing process is able to guarantee an excellent quality coating.

It serves to protect metals from galvanic corrosion by hindering the formation of electrolytic micro-cells with anodic action in the grain boundaries.

WHY CHOOSE US?

MG ITALY sees its customers as partners, placing them at the center of its corporate vision. The customer's needs prove to be a stimulus to progress in new and increasingly performing technologies. MG places the customer and his needs at the center of company choices.

The corporate philosophy of the MG Group is based on win-win. If the customer wins, MG wins too

The historicity of the group has allowed it to develop considerable know-how in the sector.

Our technical staff, thanks to their considerable experience, will be able to respond to any of your needs in a responsive manner and with excellent quality and innovative solutions. A unique service that has allowed us, over the years, to attract the attention of companies on a global level. We optimize your production with:

We use the latest generation CNC machine tools, CAD-CAM software techniques, traditional control instruments and DEA testing. We also have an organized assembly department with which we can guarantee the complete supply of assemblies or subgroups according to customer specifications.

MG ITALY has obtained the certifications:

A fundamental lever for company development is multi-year knowledge based on continuous technical updating and the maintenance of high quality standards in order to ensure high company competitiveness.

The company management has thought of a flexible and adequate structure built according to customer suggestions.