| Top machining |

Turning, Carpentry, Milling, Heat treatments

|

|---|---|

| Max turning |

pieces from Ø 100mm to diam. 2000mm, lengths from 10mm to 3000mm

|

| Max milling |

pieces from Ø 50 mm to 1000 mm in milling

|

| Other processes |

Assembly, Sandblasting, Painting

|

| Operating sectors |

Food, Electromechanics, Infrastructures, Winches production, Mechanical transmissions

|

| Work area | 9205 m² |

| Employees | 45 |

| Metals/Materials |

Steels, special steels, aluminum alloys, iron, cast iron

|

| Favorite lots |

Small series, unique pieces, lots of 6/8/10 pieces

|

| Certifications |

ISO 9001: 2000

|

LMT Solution was founded in 2002 and has grown from 20 people to 43, continuing to expand over the years. Our most appreciated and valuable feature is that we are able to follow the entire production process starting from casting to painting, passing through all processes up to assembly.

We have focused everything on quality and service and therefore on all the organization necessary to be able to guarantee them to our customers. Furthermore LMT Solution is able to process both pieces in series and single pieces.

Box for planetary gearbox

Material: S35 steel

Dimensions: diameter 1000, h 2300

Weight: 1800 kg

Processing: welding, turning, milling

Sector: mechanical transmissions

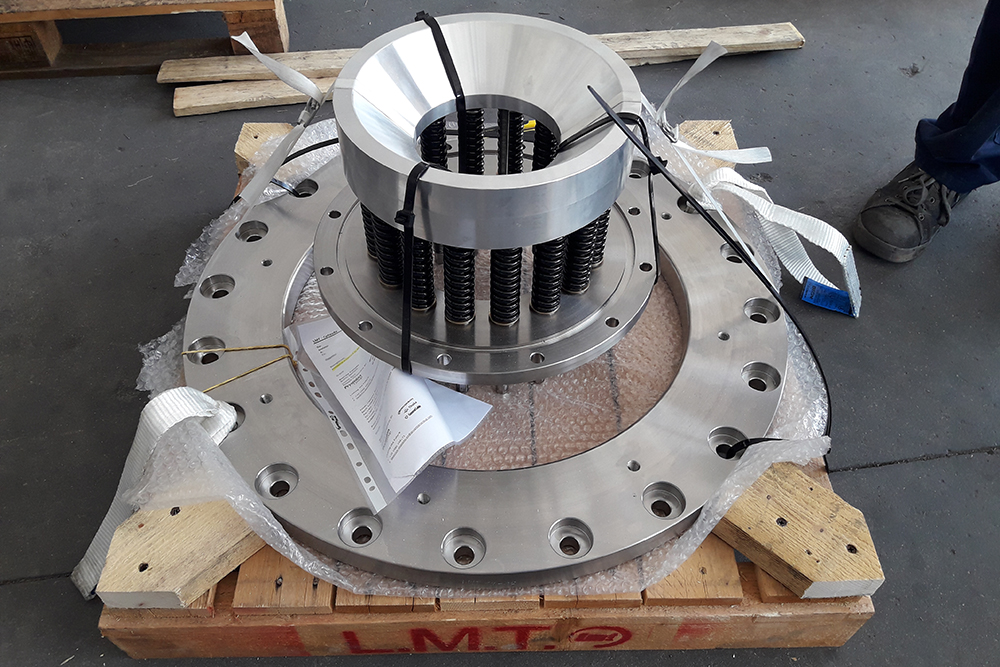

High voltage thrust system

Material: 6082 aluminum alloy, AISI 304 steel

Dimensions: diameter 700, h 400

Weight: 80 kg

Treatments: pickling, anodizing

Processing: turning, assembly

Sector: infrastructure

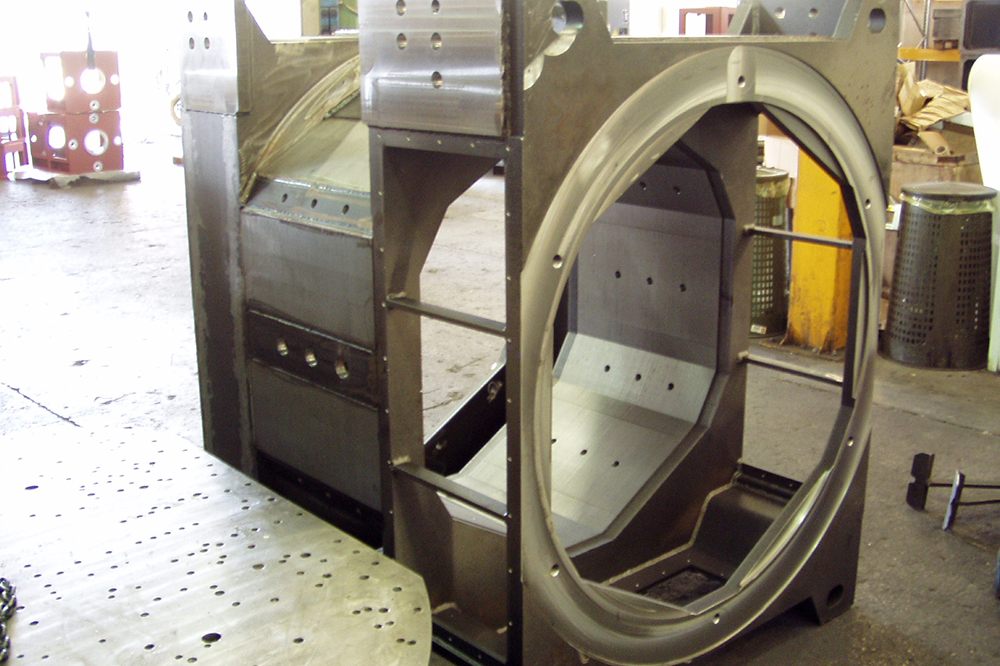

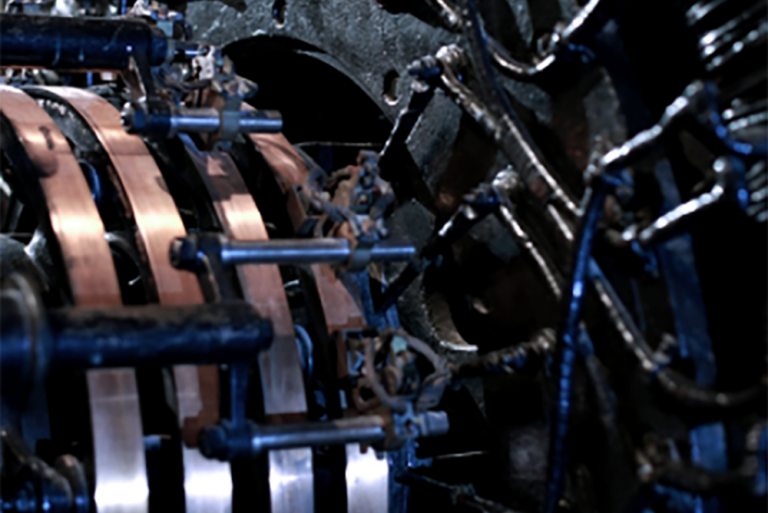

Stator for direct current electric motor

Dimensions: 1750x1600

Weight: 5600 kg

Material: Fe355

Processing: welded carpentry; milling and drilling

Sector: electromechanics

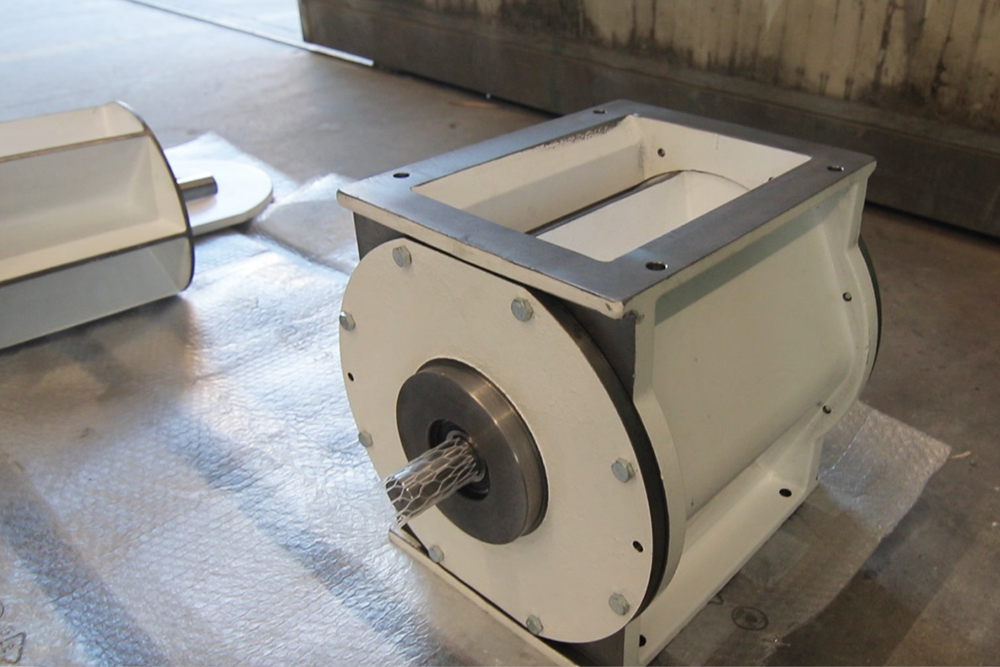

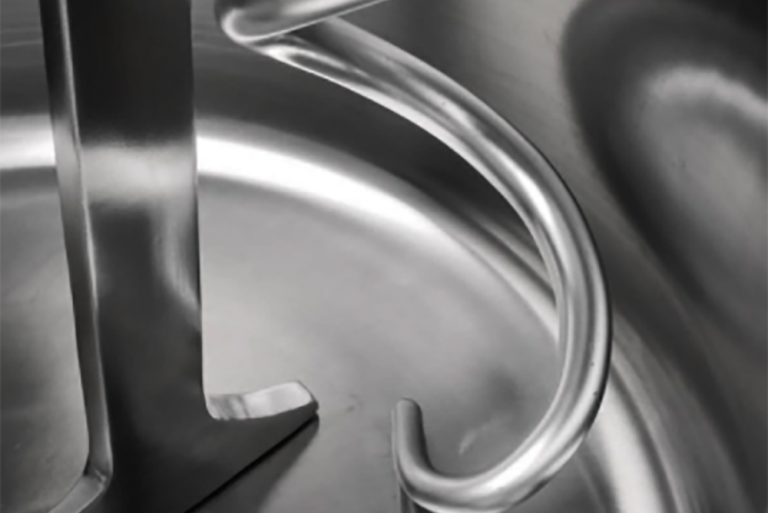

Star valve for flour and grain processing

Dimensions: 450x320

Weight: 80 kg

Material: cast iron G25, Fe 355, bronze B14

Work undergone: turning, milling, painting, assembly

Sector: feed

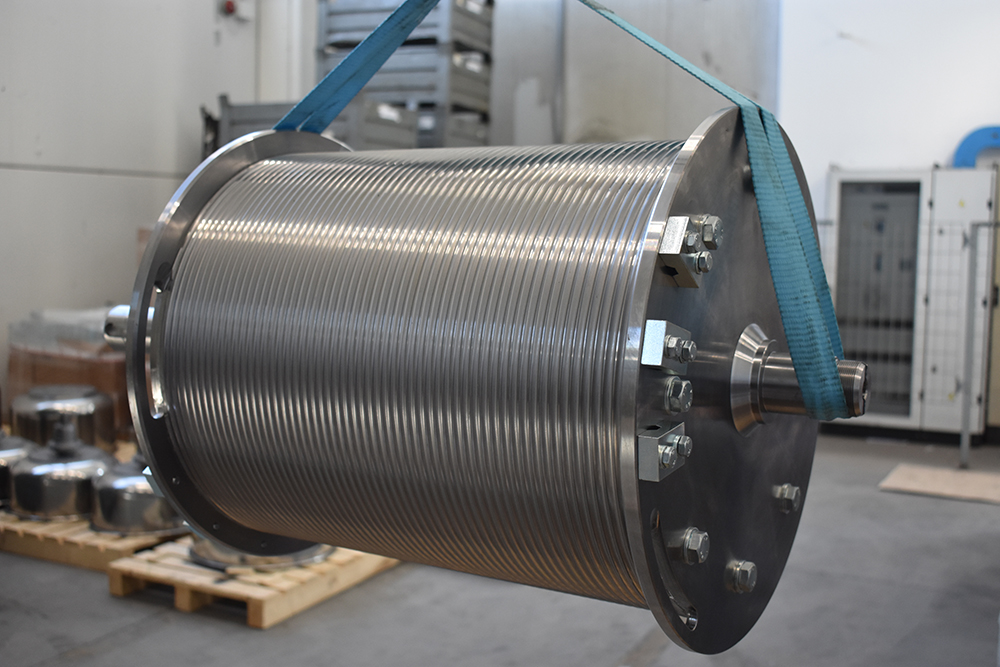

Rope winding drum for winch

Material: S355 steel

Dimensions: diameter 450, h 480

Weight: 150 kg

Work undergone: turning, assembly

Sector: winches production

Construction of medium-heavy metal structures based on the customer's design with welding, NDT controls and welding processes according to UNI EN ISO 15614.

Annealing, stress relieving and normalizing on request.

Cluster sandblasting, max dimensions 3,000 x 3,000 cm.

Liquid painting.

Horizontal and vertical CNC turning with 2,3 and 5 axes, max 2000 turning, max length 3,200 mm.

Vertical and horizontal CNC milling on continuous tables, max dimensions 6,000 x 1,500 x 2,200 mm.

Assembly of parts of our production also with commercial parts.

LMT Solution follows a precise intervention program to guarantee customer satisfaction from every point of view: product quality, production times, cost-effectiveness of procedures and processing.

From an initial consultancy phase in which the feasibility study is elaborated together with the customer, we move on to the project development, through which it is possible to establish the entire production path from the raw material to the finished product. At this point, prototypes are made, their compliance is checked and any changes are made. The product is then introduced into the production flow using advanced numerically controlled machining centers. To guarantee a high level quality, LMT Solution also has a metrology room. In addition, the component assembly service is available to provide finished and ready-to-use products. Finally, logistics implements the kanban * approach to provide a personalized service to the customer and ensure maximum compliance with deadlines.

* kanban: Japanese term meaning "teaches". Logistics method used by Toyota to replenish stocks as they are consumed.

The food sector is one of the main recipients of LMT SOLUTION products. The company is able to meet the needs of customers who operate according to high quality and safety standards. Components of bakery machines are manufactured and assembled, as well as star valves used in dosing systems.

LMT SOLUTION has always operated in the electromechanical sector, producing components for electric motors, such as casings for DC motors with shaft heights from 132mm up to 900mm. The carpentry, the packing of the sectors and the final processing are supplied. We also produce motor and shaft attachments for AC motors.

Our company has a consolidated experience in the production of components for large infrastructures such as bridges, stadiums and works for the transport of energy sources. The most stringent standards required are scrupulously observed, starting from the raw material and for all subsequent processing phases, through destructive and non-destructive tests.

For years we have been alongside important manufacturers of lifting winches. Based on customer specifications, numerous carpentry or casting components are produced and processed. The long experience in the sector allows us to tackle even large projects, providing a consolidated wealth of knowledge and skills.

The long-standing collaboration with leading manufacturers of mechanical transmissions has allowed LMT SOLUTION to specialize in the production of components for gearboxes, such as bodies, covers and supports and torque arms for gearboxes up to 2.500.000 Nm. Pre-assembly can also be supplied on request.

Machine name: DOOSAN NHP8000

WORKING DIMENSIONS: equipped with N ° 2 pallets (pallet size 800x800 mm; admitted load = 2.000 kg .; max dimensions in rotation ø 1.450 xh1.550), continuous rotating table, Renishaw probe for pallet self-centering, spindle with 10.000 rpm, pallet changer; internal coolant supply, X axis travels = 1.400 Y = 1.050 Z = 1.200, 90 tools magazine

Machine name: MAZAK FH 880

WORKING DIMENSIONS: with Mazak FMS (palletizer) of 16 pallets and 2 loading / unloading stations (pallet size 800x800 mm; max piece weight = 1.500 kg .; max piece size ø 1.250 xh 1.250), Mazatrol MPLUS control unit, presetting, Renishaw probe for pallet self-centering and workpiece measurement in the machine, spindle with 7.000 rpm, BT50 spindle connection, X = 1.300 Y = 1.100 Z = 1.000 axis travels, 160 tool magazine, chip conveyor

Machine name: LAGUN GMM6

WORKING DIMENSIONS: longitudinal axis strokes X = 6.000, transversal ram Y = 1.200, vertical Z = 2.000, transversal table movement V = 1.500, N. 2 continuously rotating roto-translating tables, 1.500x1.500 mm worktop with a capacity of 10.000 kg universal automatic bi-rotary, rotation speed 4.000-5.000 rpm, Renishaw three-dimensional probe for centering, alignment and inspection of the piece, magazine with 60 tools, pendulum machine management (2 separate work areas)

Machine name: DOOSAN PUMA 1000M

WORKING DIMENSIONS: inclined bench in cast iron, max. swing over bed 1.000 mm, max. bar turning 375 mm, max. rotating on 1.250 mm bed, max. rotating on carriage 950 mm, max. turning between centers 2.040 mm, tool turret with 12 stations, motorizable turret stations = 12, pneumatic self-centering with built-in cylinder BB-N 800/410, spindle hole diameter 375 mm, maximum permissible cantilever weight 3.000 kg. tailstock 7.000 kg.

Machine name: PUMA 600LY

WORKING DIMENSIONS: max diameter turning 750 mm, max. rotating on 1.140 mm bed, max. rotating on carriage 1.000 mm, max. turning between centers 3.250 mm, X axis travel = 400 Z = 3.300 Y = 200 (+/- 100) C (spindle rotation) = +/- 360 °, motorized turret with 12 tools, self-centering diameter 630 mm (with variations of 2 pressures on the chuck), tailstock with stroke equal to 3.085 mm, self-centering hydraulic steady rest with capacity 85 - 350 mm, maximum permissible cantilever weight 900 kg., Maximum permissible weight with tailstock 5.500 kg

Machine name: PUMA 400LM

WORKING DIMENSIONS: max diameter turning 560 mm, max. rotating 770 mm, length max. turning 2.028 mm, 12-station turret with motorized tools, hydraulic tailstock, self-centering diameter 400 mm

Machine name: KDM mod. KTM 16/20

WORKING DIMENSIONS: table diameter 1.600 mm (6-jaw hydraulic self-centering with variations of two pressures), X-axis cross travel = -250 ÷ +1780 mm, Z axis vertical travel = 1.000 mm, furniture vertical travel = 750 mm, max. rotating 2.000 mm, max. swing 2.000 mm, max. turning 1.750 mm, basket tool magazine 8 + 8 stations, vertical angle head for milling / tapping / drilling with ISO-50 connection, max. permitted load on the table 10.000 kg

Machine name: DOOSAN PUMA MX 3100S

WORKING DIMENSIONS: max diameter turning 760 mm, max. rotating on a 1.000 mm bed, max. rotating on carriage 700 mm, max. turning between centers 1.540 mm, tool change (40 tools magazine), self-centering diameter 450 mm, self-centering counter spindle ø 315 mm

In the quality section work Petra and Kevin, who from the metrology room take care of the whole process of measurement, documentation and preparation of the work for the personnel assigned to the machines.

The pieces are checked both during the processing phase and when the piece is finished to identify any non-conformities. We prepare the documentation required by the customer, sheets relating to the finished pieces and prepare the measuring devices for the instruments on the machine.

DEA measuring machine: three-dimensional, measurable dimensions axis X = 1.450 Y = 1.000 Z = 900. Instrument precision 10 –7 m (10 –4 mm).

Anthropomorphic portable three-dimensional measuring arm: measuring range (spherical diameter) 2,5 m, length measurement accuracy: + - 0,034 mm, repeatability: + - 0,017 mm

TRIMOS horizontal tool reset bench Mod. HORIZON H2000: measuring range 2.020 mm, resolution 0,001 mm

Since 2006, the LMT Srl Quality Management System has been certified in accordance with the ISO 9001: 2000 standard

LMT Solution has customers throughout Italy and Europe and has also worked internationally. It can therefore meet the needs of a new clientele anywhere in the world.

LMT Solution has been supporting the production of kneading machines for bread-making for this strategic customer for years. The service given to this customer includes various stages of the production process. Starting from the casting, we carry out all the mechanical machining of turning, milling and treatments, necessary for the realization of the components, subsequently including painting, assembly and storage. A real full service. The relationship with this customer represents the mentality and the willingness of LMT solution to evolve by continuously putting the needs of its customers at the center.

“In short, we can confidently assert that LMT represents an integral part of our production activity for us. It has long been no longer a simple supplier. "

Production manager

Luca - He has been with us for a couple of years, graduated in Political Science at the University of Padua, speaks 3 languages and is our business consultant. It is helping us a lot in the growth and continuous evolution of our business. Customers can count on Luca and his availability to solve any problem for which LMT can be useful.

- Vittorino Manfro - Owner

Davide - Machining center programmer. Davide has been with us recently and testifies to the constant search for skills that are vital and necessary to give service. Davide has been working in the sector for years despite his young age and has accumulated important experiences that he is putting at the service of our company and our customers, who I am sure will be able to count on Davide for a long time.

- Vittorino Manfro - Owner

To ensure an increasingly complete service to LMT customers, as soon as the health emergency is completely overcome, we will resume the renovation project of our production facilities with the construction of an additional warehouse that joins the two of the Sossano production center. We renovate and optimize spaces in search of more functional logistics.

We continue to invest and believe in the future.

- LMT Solution SRL

LMT was among the first 20 companies to join this digital fair. It was also the first to provide the material necessary for the preparation of the first actual stand. We believe that the world of B to B marketing is evolving and that this initiative is absolutely in step with the times. We want to keep evolving and growing. We are proud to be the first to be published.

We had faith in the specialist marketing team and their idea, their enthusiasm infected us. But in this case, at least, it is a contagion without danger, but only benevolent.

- LMT Solution SRL