| Top machining |

Adjusting, Anodizing, Assembly, Boring, Burnishing, Threading, Drilling, Milling, Tapping, Taping, Deburring, Slotting, Turning

|

|---|---|

| Max turning |

200 x 350

|

| Max milling |

600 x 1400 x 500

|

| Other processes |

Painting, Galvanic Galvanizing

|

| Operating sectors |

Industrial Machinery, Medical, Construction Racing, Hobby, Mechanical Transmissions, Doors and Windows, Other sectors

|

| Work area | 600 m² |

| Employees | 6 |

| Metals/Materials |

Steels, Special Steels, Aluminum, Aluminum Alloys, Bronze, Iron, Brass, Special Metals

|

| Favorite lots |

Single piece, small series 50pcs, periodic series 250-500pcs

|

| Certifications |

In the process of ISO certification

|

CS Mechanics is a trademark of CHIAROSCURO SAS. CHIAROSCURO since 1998 it has been providing its customers with mechatronic solutions for the automation of doors and windows, actively contributing to the safety and energy saving of the building.

In 2013 the partners Luca and Marco Girelli decided to bring mechanical production home. This has allowed CHIAROSCURO a leap forward for product quality, flexibility and technological innovation.

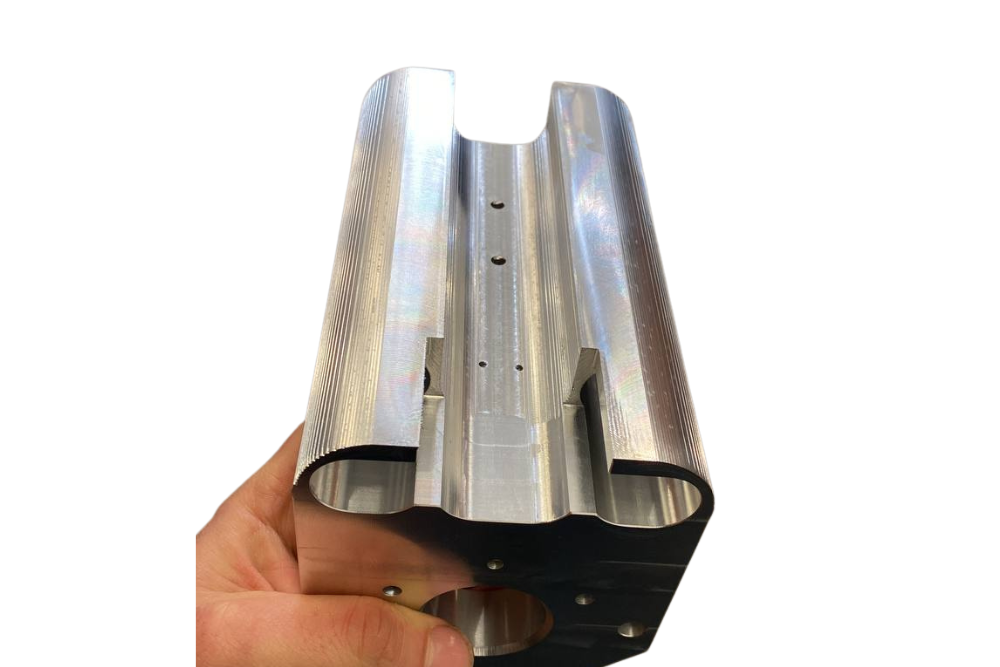

Example of product processed in CS Meccanica - For more information, contact us

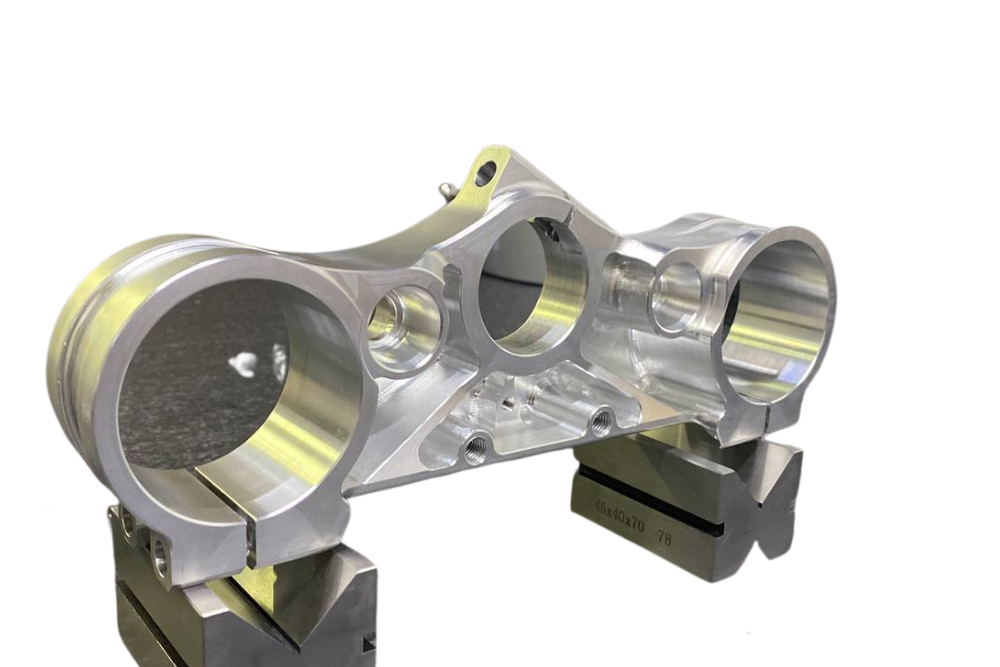

Motorcycle Fork Support - For more information, contact us

Example of product processed in CS Meccanica - For more information, contact us

Example of product processed in CS Meccanica - For more information, contact us

Example of product processed in CS Meccanica - For more information, contact us

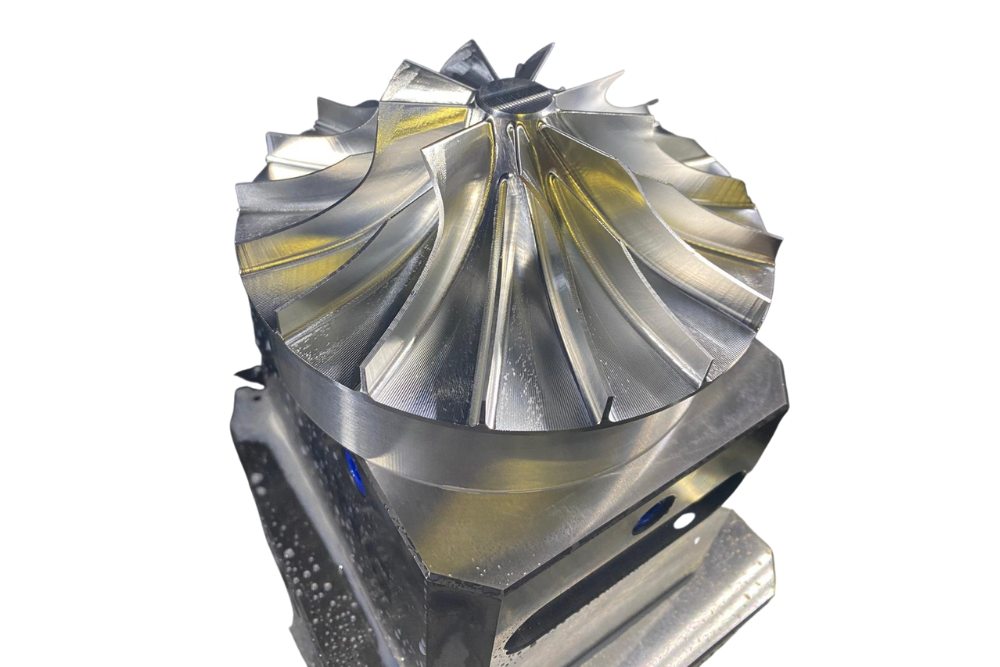

Turbine Section - For more info, contact us

Complete Turbine - For more info, contact us

Our technicians carry out precision adjustment operations by hand, on the bench, to always offer top quality. (traditional lathes and cutters)

To carry out anodizing processes, we rely on expert external partners.

We take care of the assembly of our products and carry out this process for our customers as well.

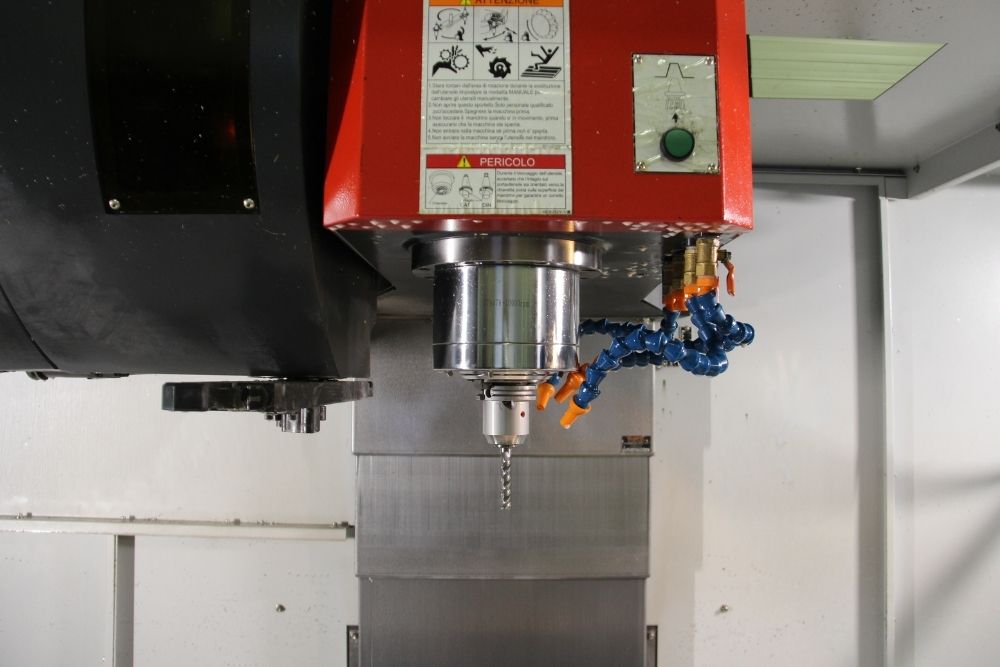

Our latest generation numerical control machines carry out very high precision boring operations.

For the bluing operations we rely on expert external partners to obtain the surface coloring of the metals.

Our latest generation numerical control machines carry out very high precision threading operations of all types (ASA, ISO, NPT etc ...)

Our CNC machines perform very high precision drilling operations.

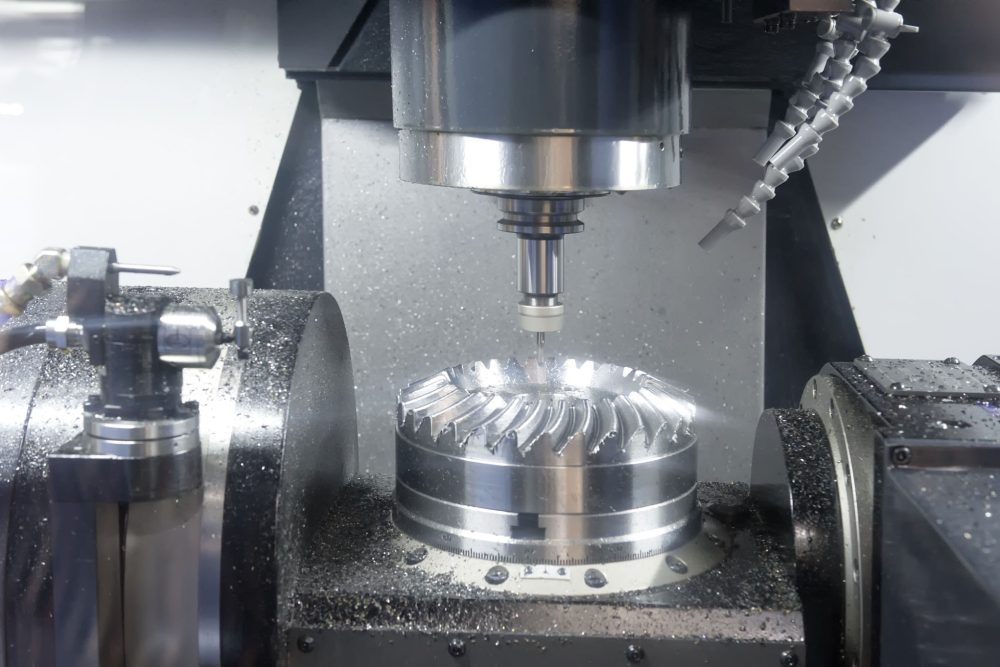

We do 3, 4 and 5 axis milling.

We carry out the threading of holes by means of rolling and removal taps.

We also deal with metal grinding operations.

We carry out removal of metal burrs.

Thanks to our slotting machine, we can carry out workings with rectilinear cutting motion and internal workings.

We carry out precision machining with our 2 and 5 axis lathes.

For the painting operations we rely on expert external partners, to obtain a surface coloring of the metals.

Even for processes that require galvanic zinc plating, we rely on expert external partners, to obtain a suitable surface finish of the metals.

Why choose your company?

In CS Meccanica we take care of producing precision mechanical components according to customer specifications. Passion for quality and precision are the driving force behind our evolution, which is why we are aware that the products we make contribute to the competitiveness of our customers.

We produce precision components for the following sectors:

Agricultural, Furniture, Automotive, Components, Construction, Doors and Windows, (automation components for doors and windows), Electronics, Railway, Hobby, Mechanic, Household appliances, Industrial machinery, Woodworking, Mechanical Transmissions, Racing (production of prototypes and precision components in small and medium series ), Micromechanical.

DOOSAN VC630

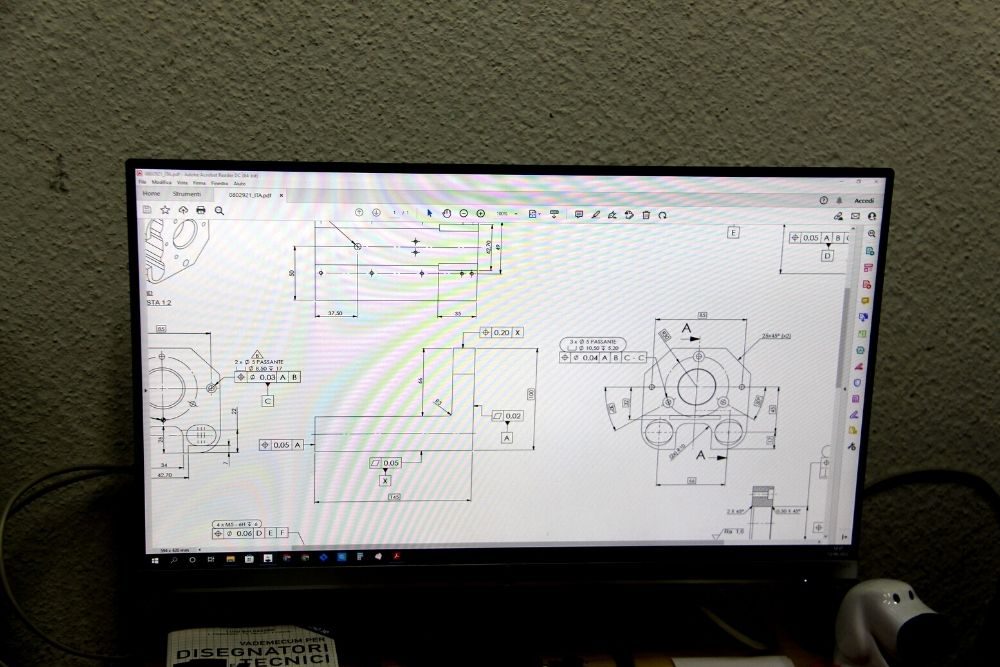

INDUSTRY 4.0: All networked, complete management from CAM programming to CAM simulation to machine production

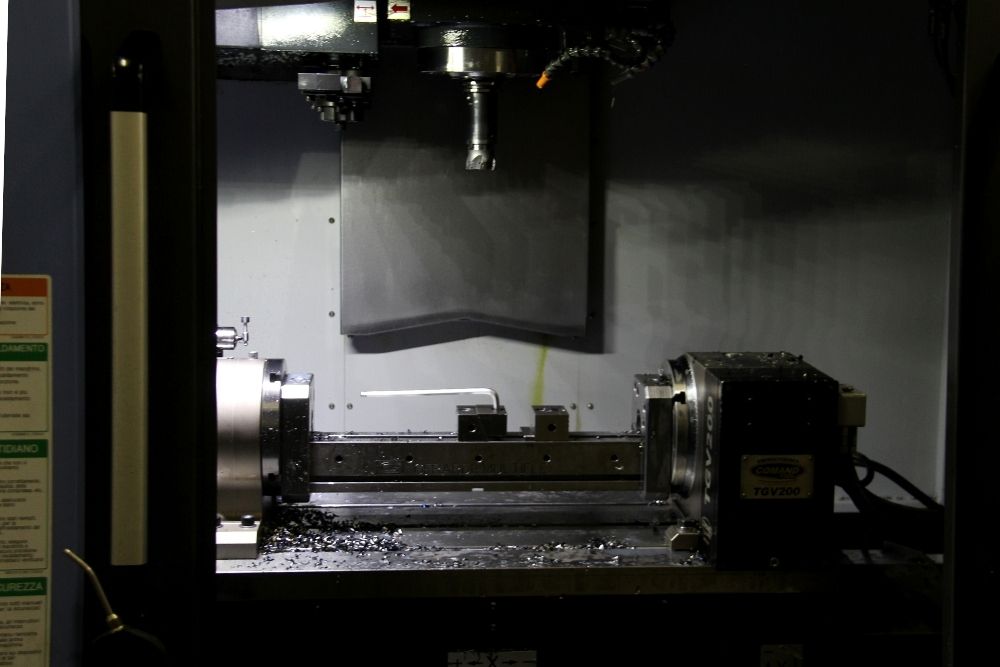

DOOSAN DNM 4500

Versatile - Machine always ready for rapid prototyping

AWEA AF 1460

Thanks to its size we can deal with pieces with important lengths

DOOSAN LYNX 2100LY

We make the most of the lathe's potential with complex turning and milling parts

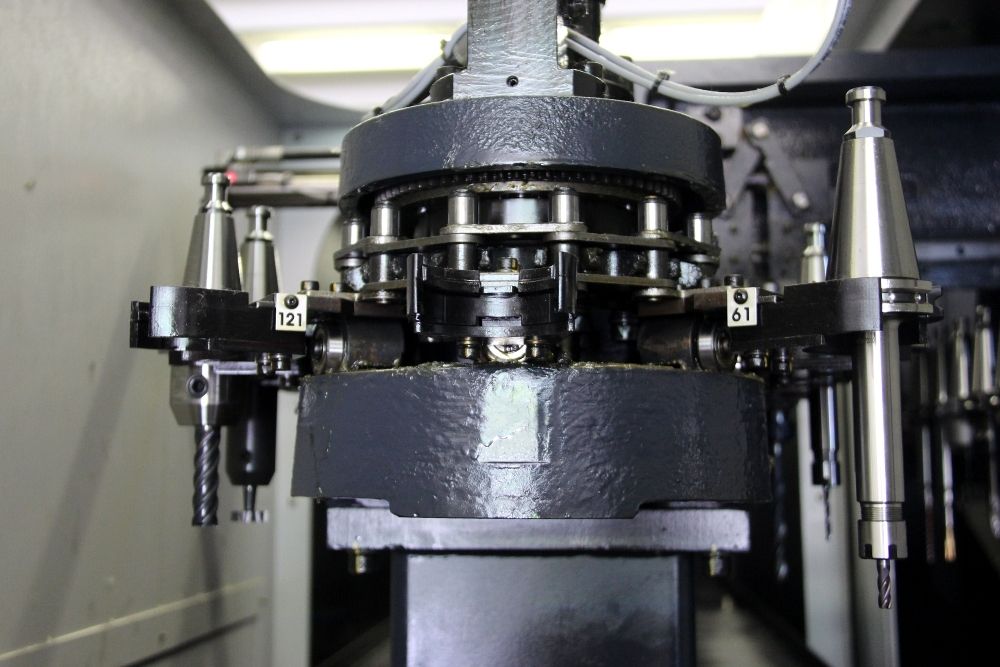

Main machinery detail

Main machinery detail

Paparticular secondary machinery

Detail of secondary machinery

The entire production process is entirely Industry 4.0 with the OSL GP90 management software. Every single process is managed online: from CAM programming, to CAM simulation, to machine production.

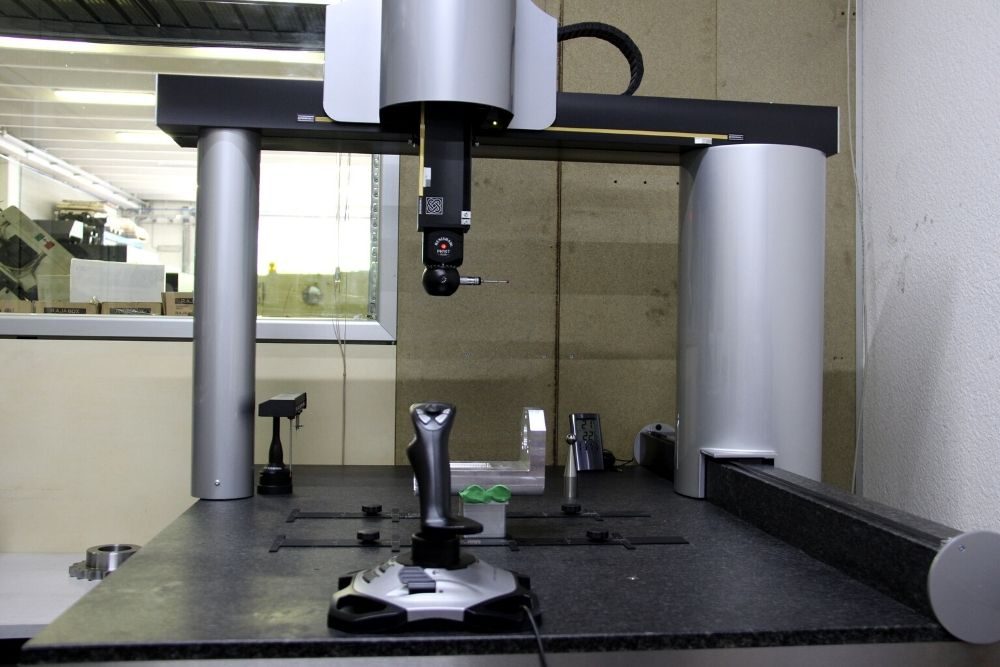

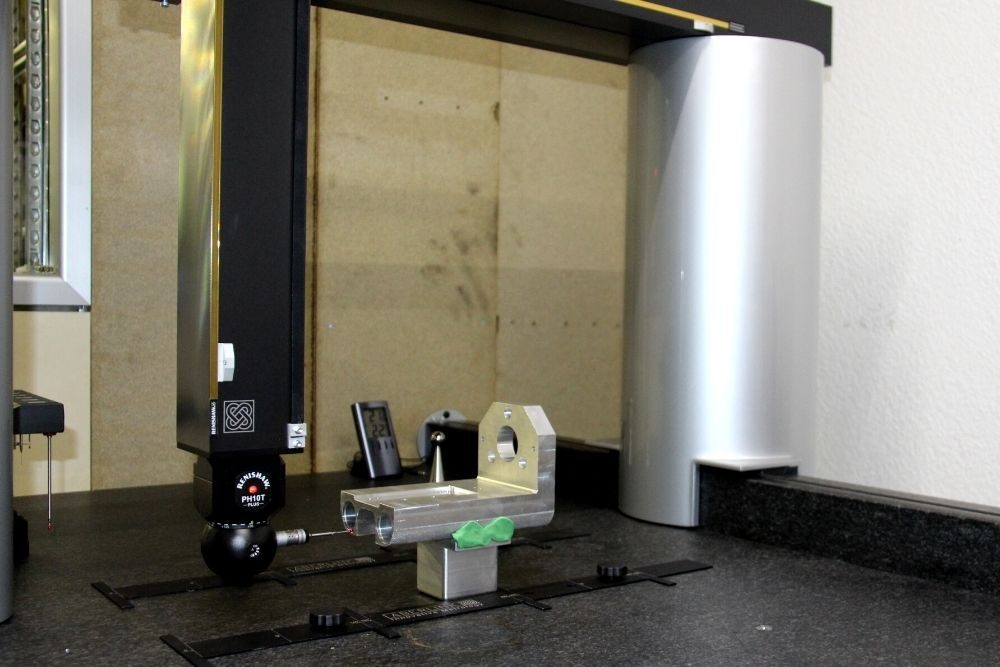

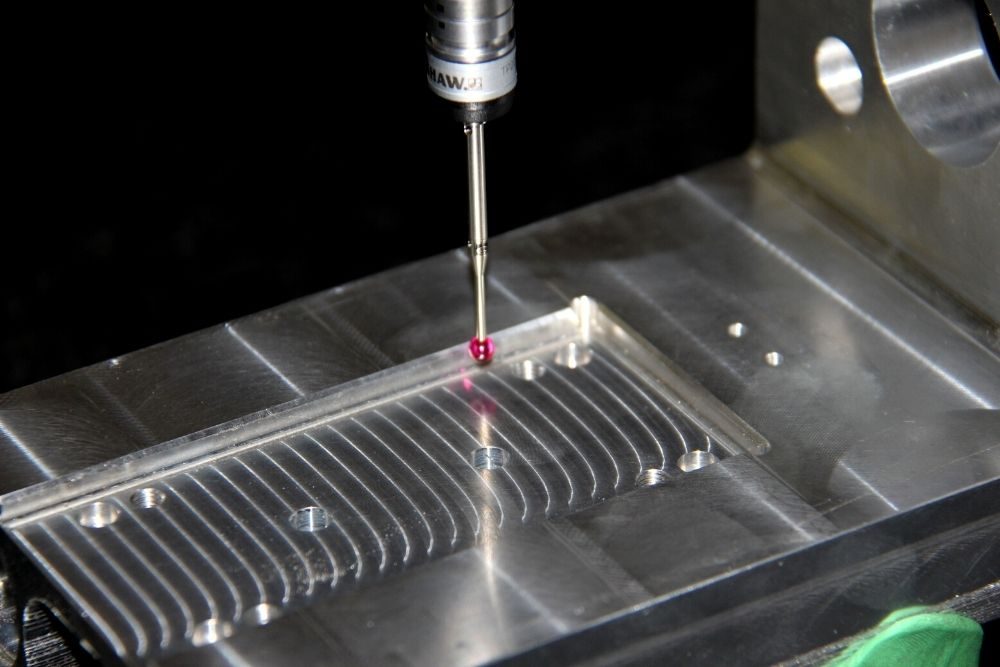

Our quality department, by means of the three-dimensional probing machine, is able to keep the quality of the product under control.

In the process of ISO certification

We have years of experience in production in the mechatronic sector for the window and door sector. We follow manufacturers of CNC machinery for cutting machines, agricultural, hydraulic and pneumatic distributors sector, casting machinery, design studios in the naval and automotive motorsport sector. And thanks to the presence of production process control systems, we are able to be fast and precise.