| Top machining |

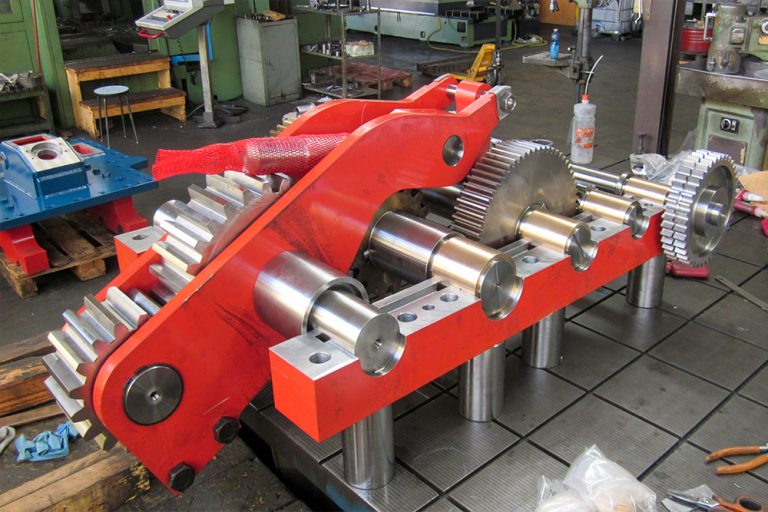

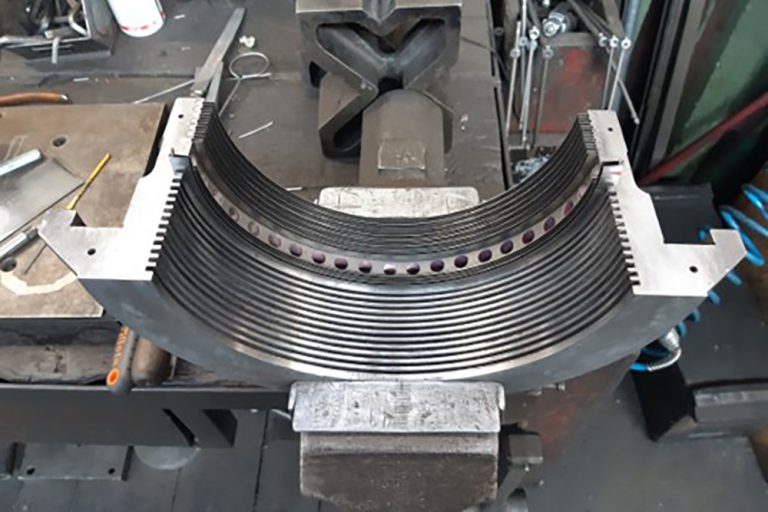

Boring, Technical drawing, EDM, Milling, Lapping, Assembly, Grinding, Slotting, Turning, Painting

|

|---|---|

| Max turning |

Max horizontal turning D. 1200mm (640 on the carriage) x 550

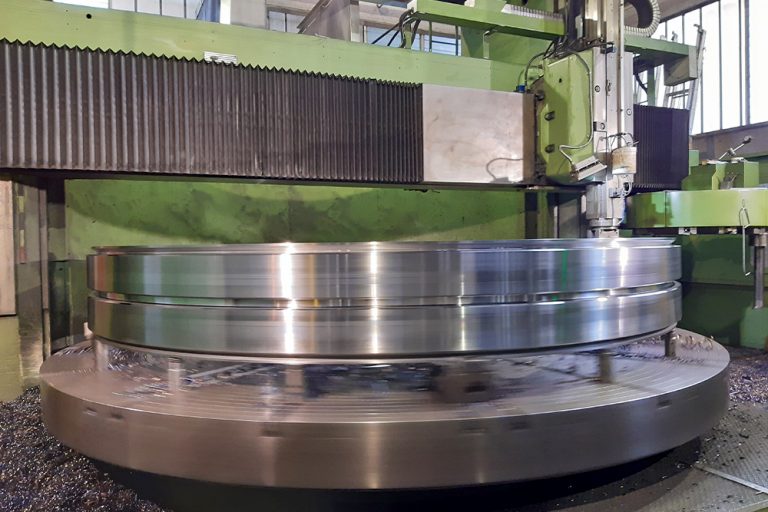

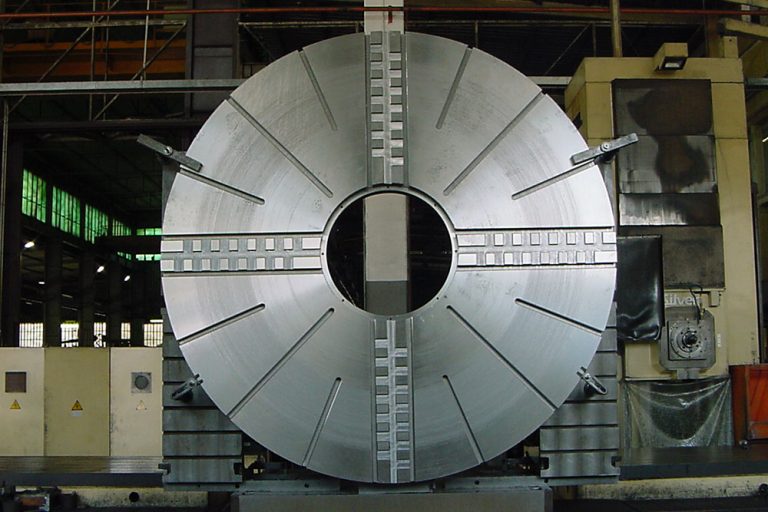

Max vertical turning D. 4200 x 2000 |

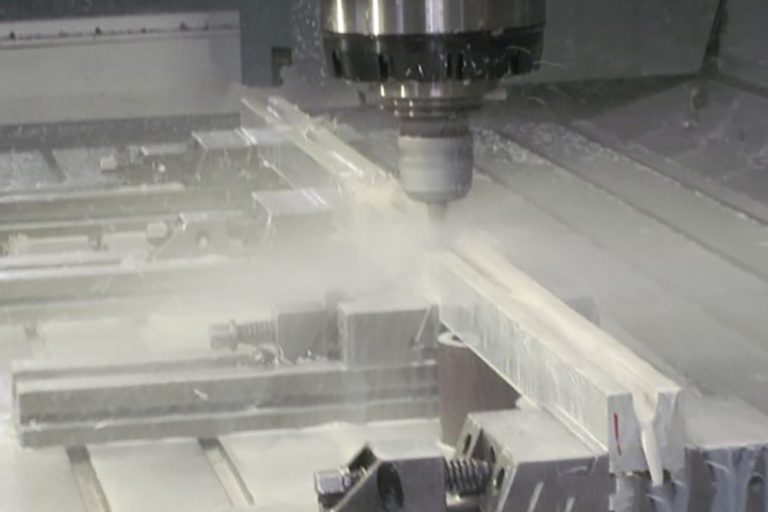

| Max milling |

Max horizontal milling 2500 x 2500 x 11000 - Max vertical milling 6000 x 2200 x 1500

|

| Other processes |

Testing, Polishing, Surface treatments

|

| Operating sectors |

Aggregate grinding, Plastics, Naval, Hydraulics, Prototyping, Other sectors

|

| Work area | 3500 m² |

| Employees | 23 |

| Metals/Materials |

Special steels

|

| Certifications |

UNI EN ISO 9001: 2015

|

Established in 1959 from the experience gained in the mechanical field by the founding members, from an initial repair of mechanical machinery and equipment, Za Ber - Officina Meccanica has developed steadily over the years.

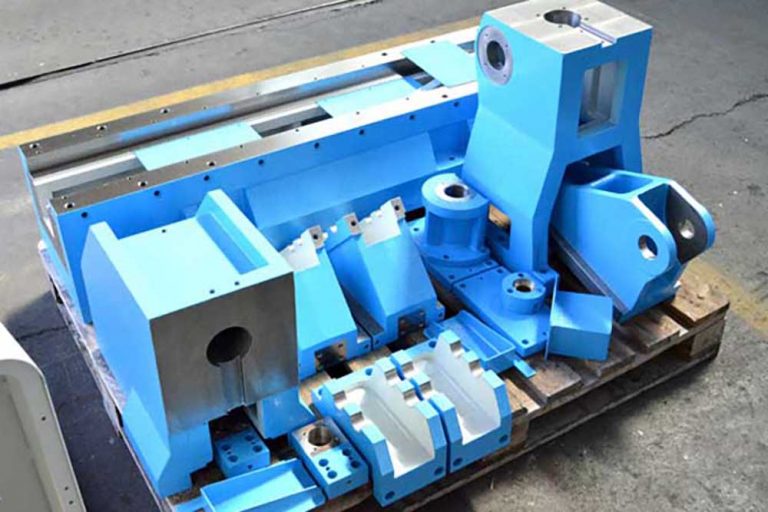

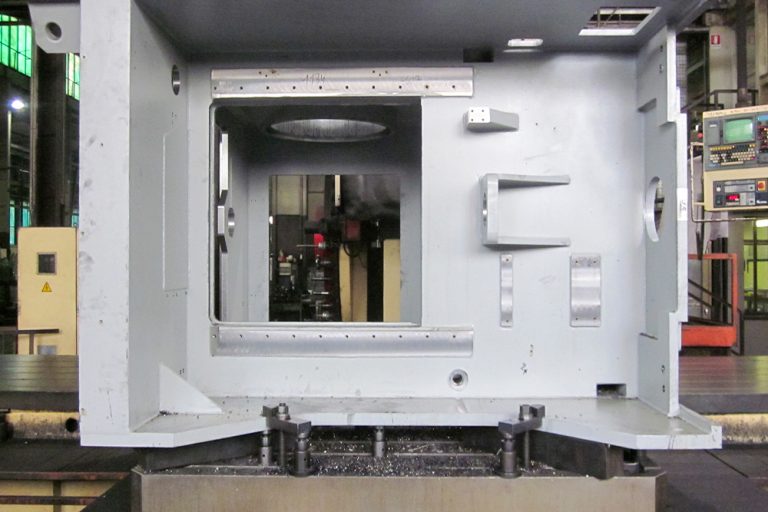

Today it is able to manufacture highly mechanical machines, equipment and parts specialized, manufactured on the basis of drawings provided by customers with modern equipment and efficient. Using a team of expert collaborators, he studies the feasibility of the project even if summarily described by the Customer.

The fruitful collaboration with the major Italian industries allows Za Ber - Officina Meccanica to boast of enviable references, able to guarantee by themselves the very high quality of the products made.

For some years now a system for industry 4.0 application has been operational for the constant improvement of processing programming, optimal control of all data relating to final processing times, machine stops, etc.

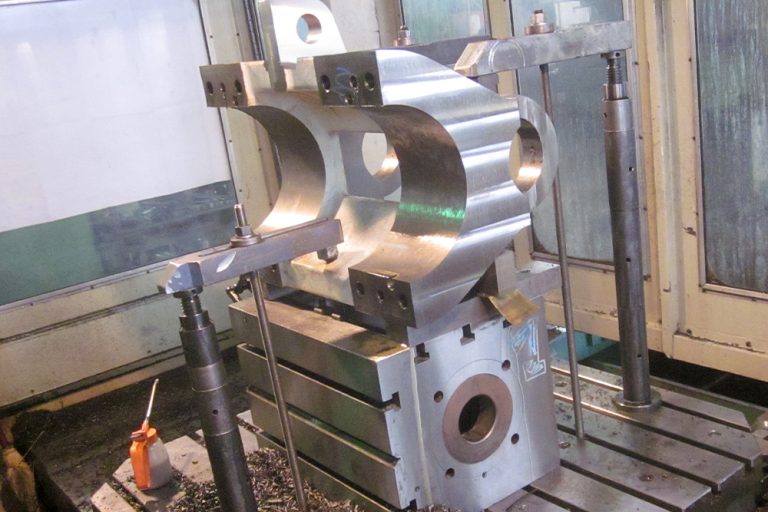

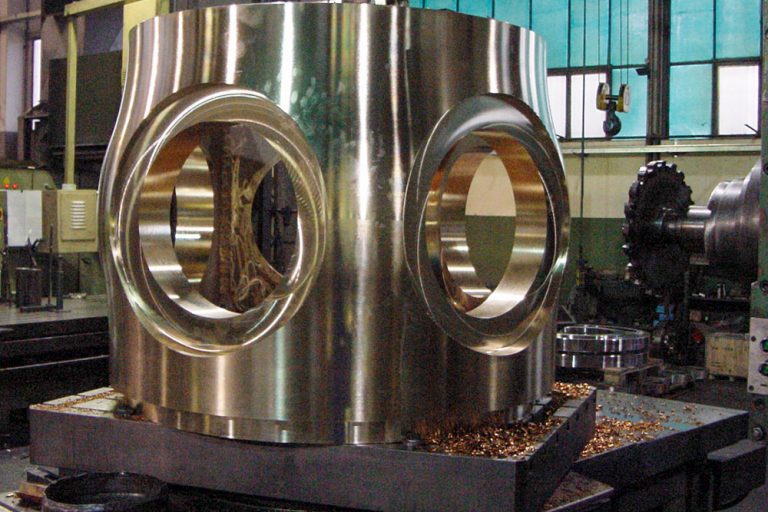

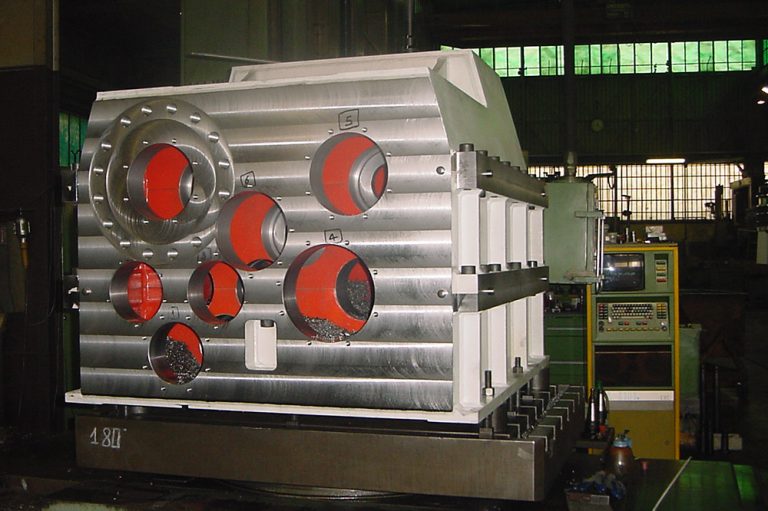

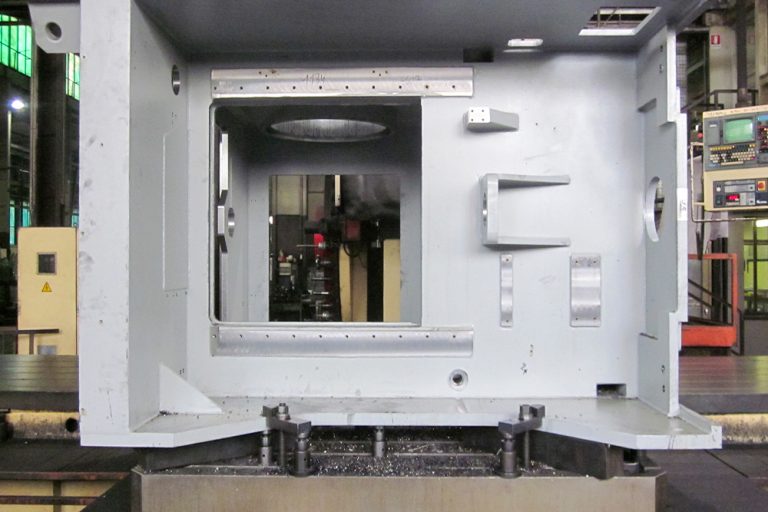

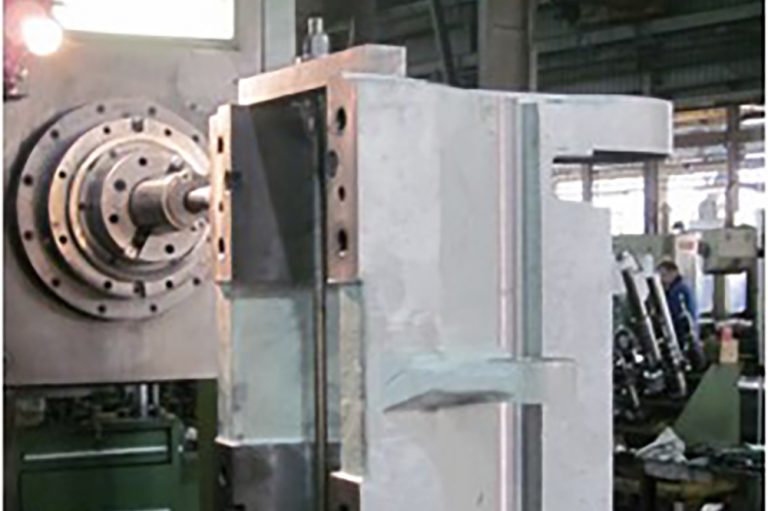

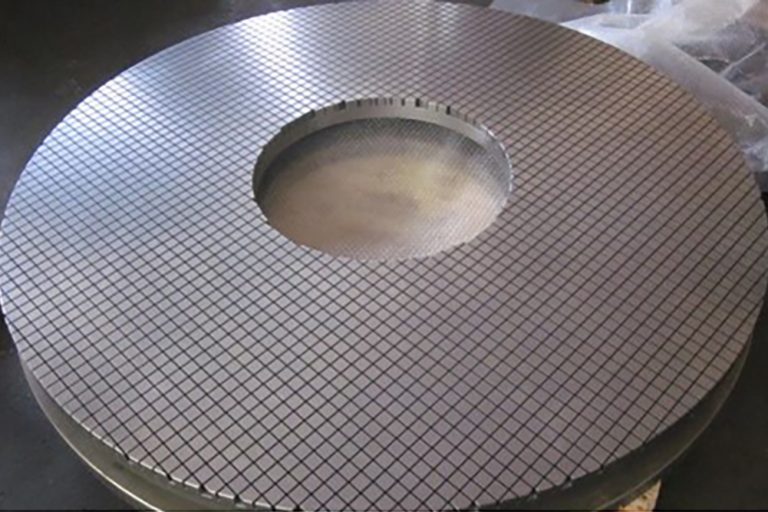

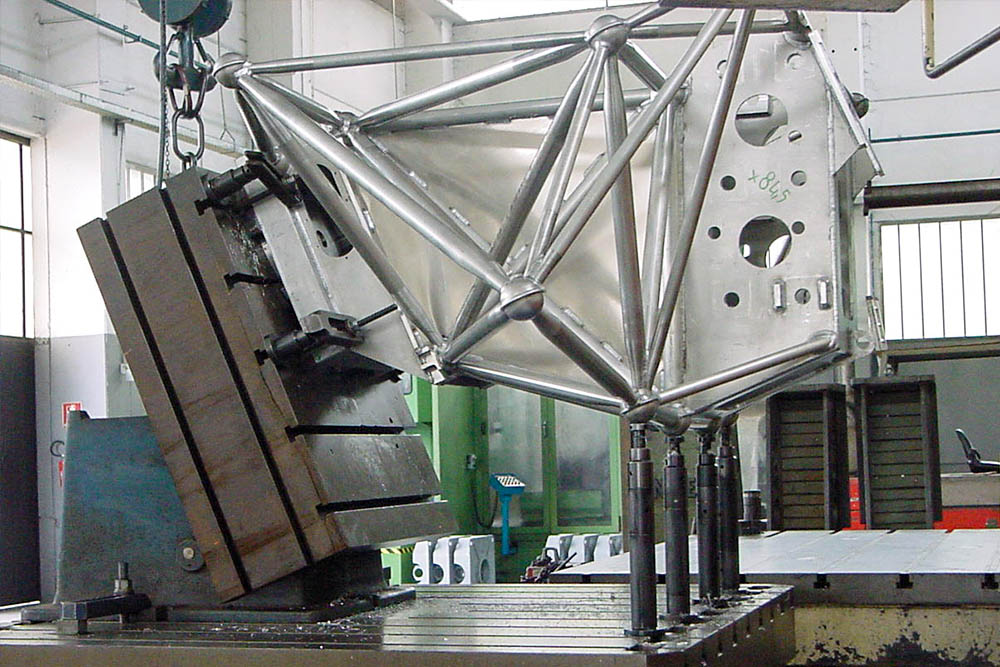

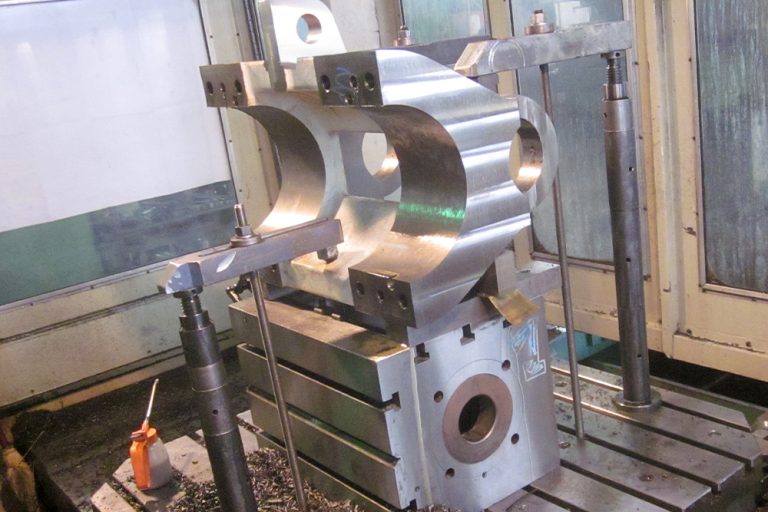

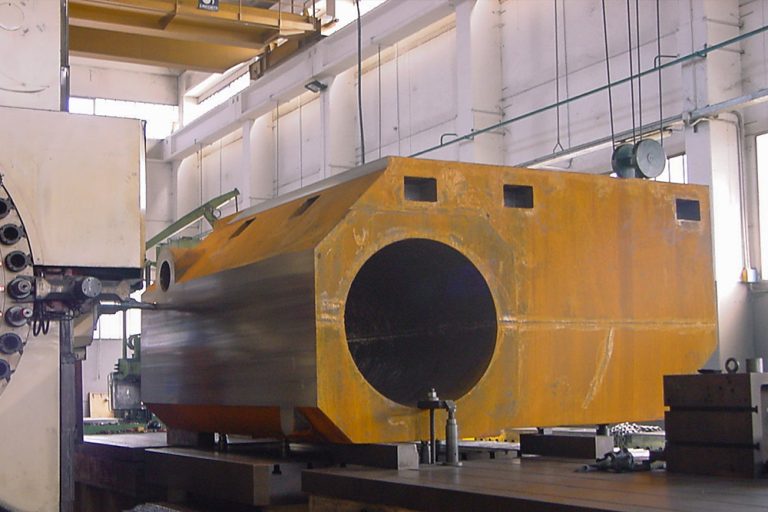

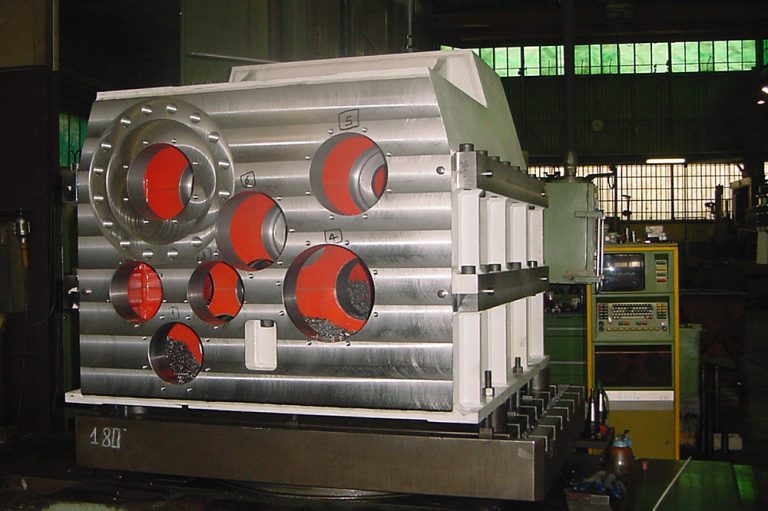

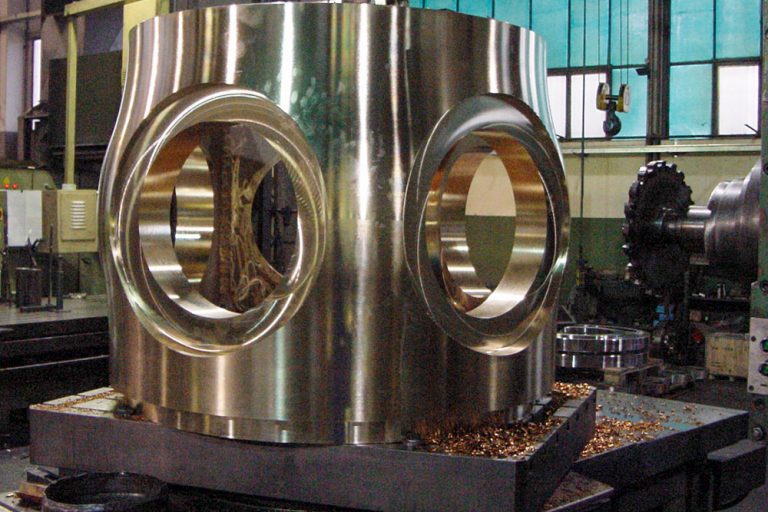

In our departments specialized in precision machining, we are able to create pieces of various sizes, up to 2200 X 6000.

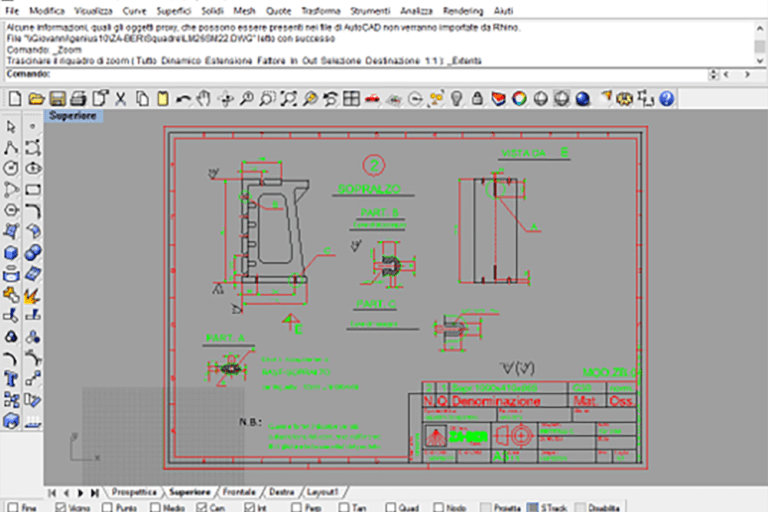

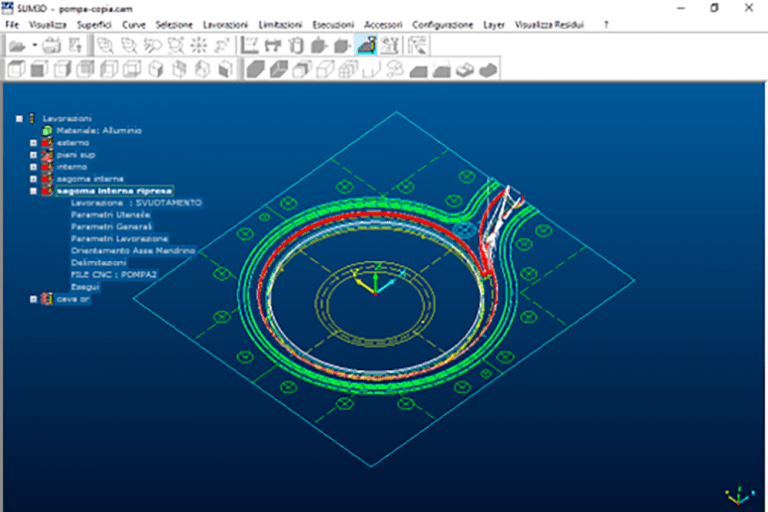

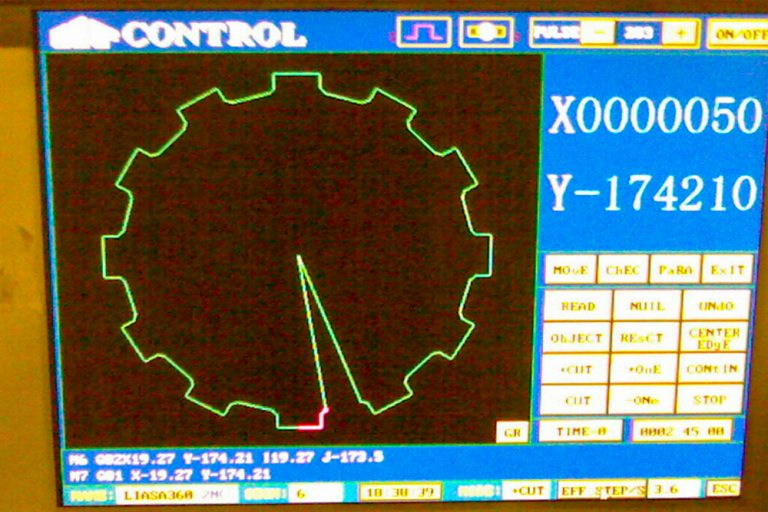

Za Ber - Officina Meccanica is equipped with a modern 3D CAD / CAM computer system made up of various networked stations.

We can make parts up to dimensions of 2.500 X 2.500 X 11.000 even with CNC machine tools.

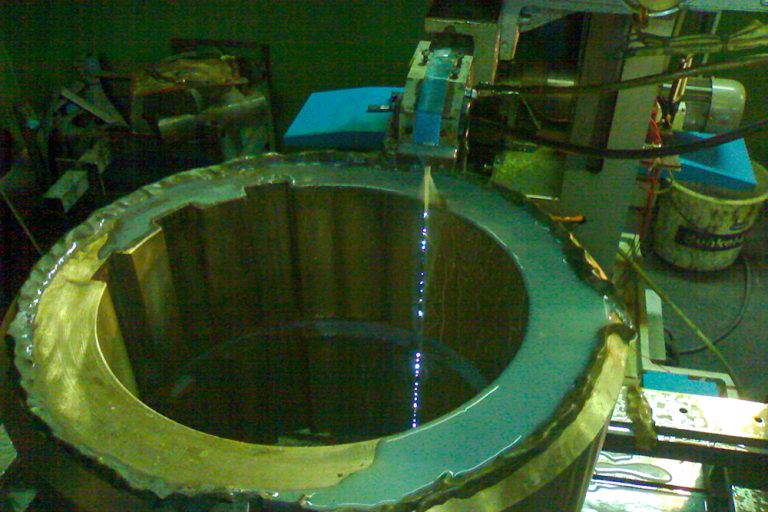

Za Ber - Officina Meccanica is equipped with a modern wire EDM machine with capacity up to 1600 mm x 1200 mm x 800 mm.

We also perform hole lapping, and we are able to lap holes up to D.600 x H.2000.

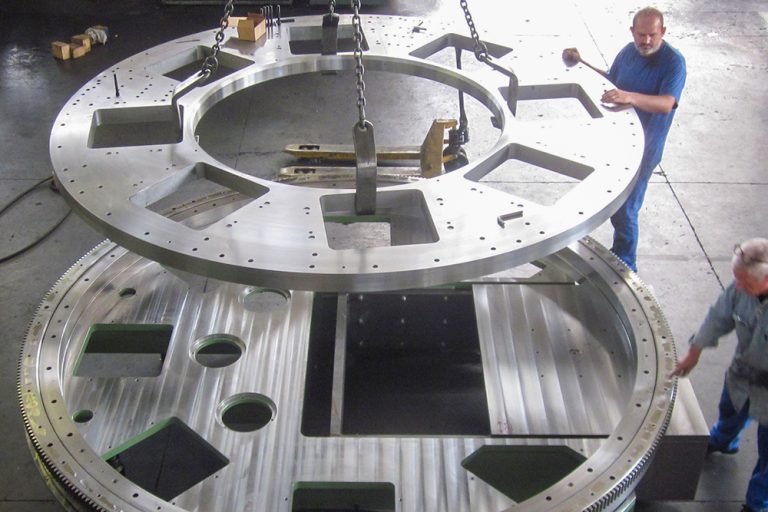

In our company, we have a large department dedicated to the assembly of more or less complex parts.

We can grind pieces with dimensions 1000 x 1000 X 4000.

We grind in the round D.600 X 2500. We can rectify holes D.150 X 300.

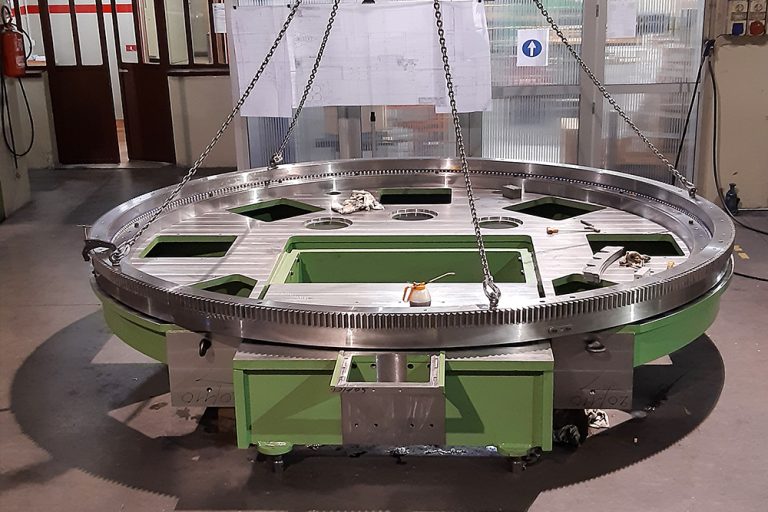

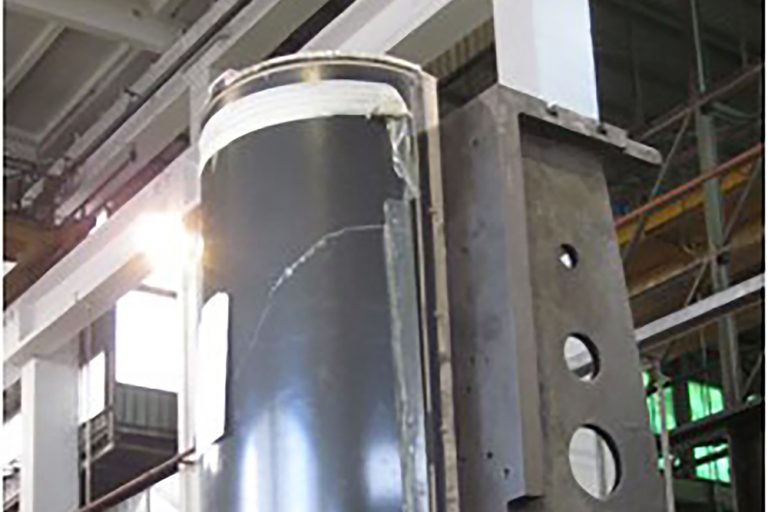

We make slots on pieces with dimensions D. 2400 x H. 1000 and slot length 1000.

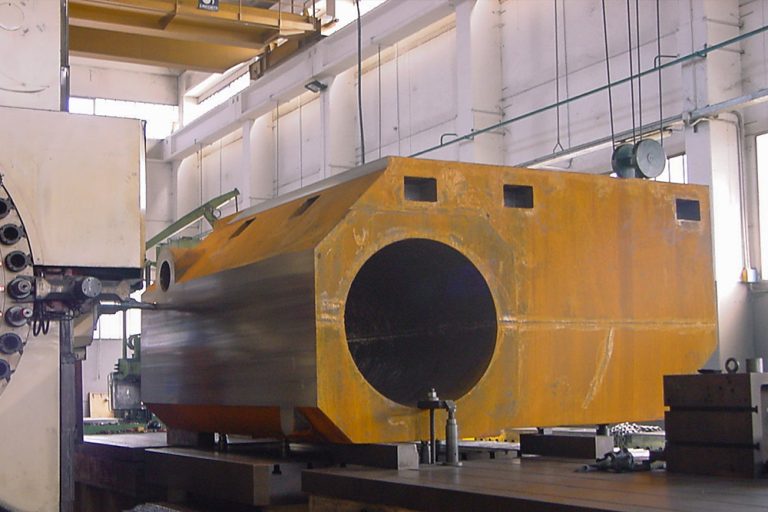

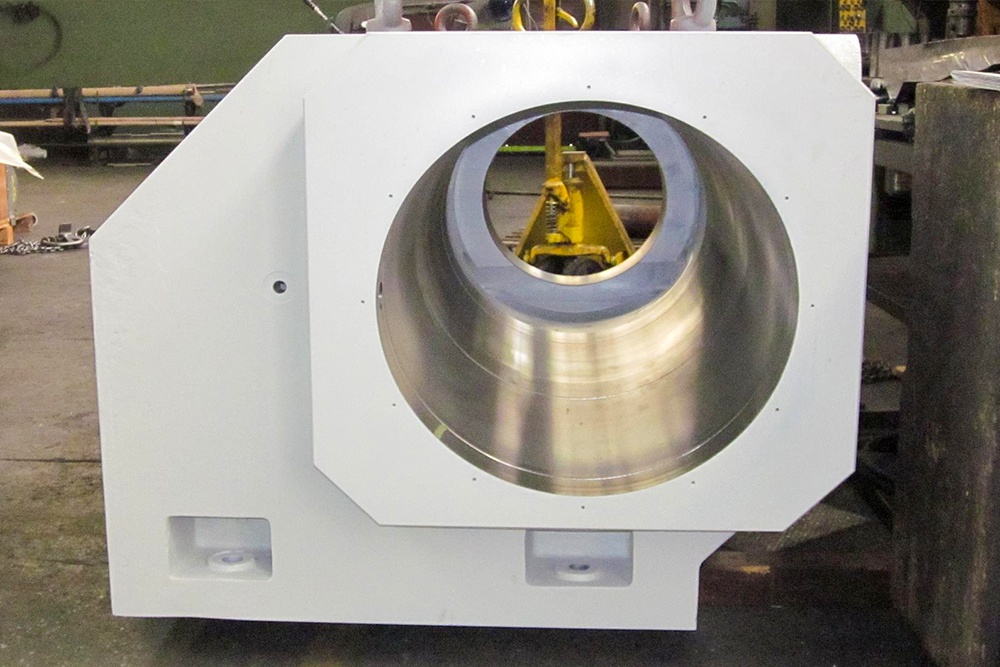

We are able to make pieces up to dimensions of D.4000 x H.2200 with vertical lathes.

D.1200 x L.6000 with CNC parallel lathes.

We are equipped with a large spray booth with dryer.

We work radar antennas and satellite components.

We also perform precision machining on parts for the food industry.

We work components for the large, small and medium-sized energy sector.

We are also specialized in the machining of parts intended for the pharmaceutical sector.

We work components for various types of systems.

We carry out precision machining on various parts for machine tools, uprights, tables, etc…

We also deal with components for plastics processing, extrusion, etc…

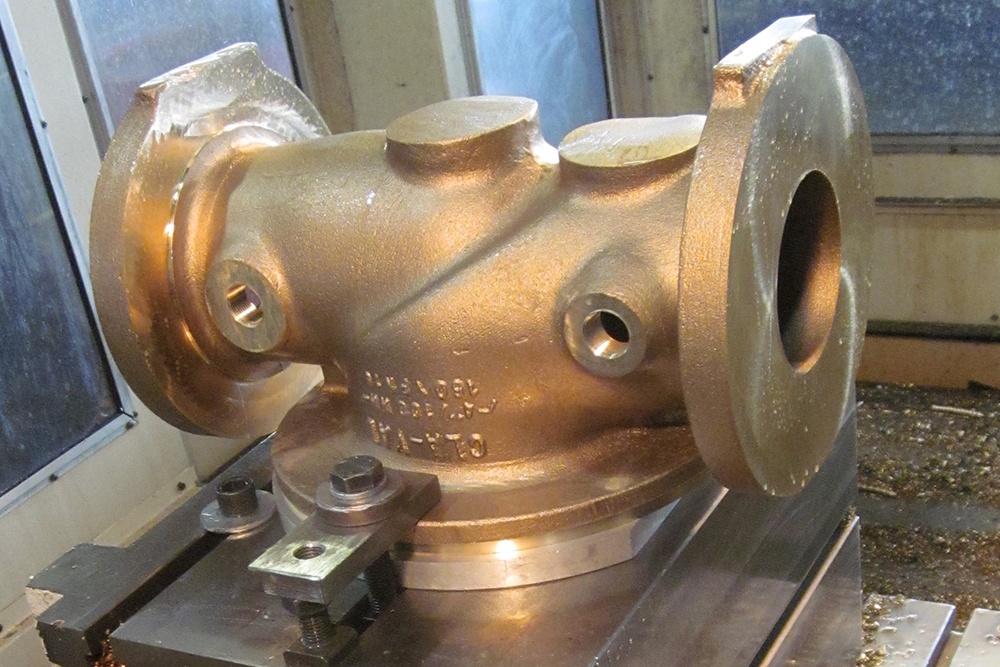

Production and processing of details for the naval sector.

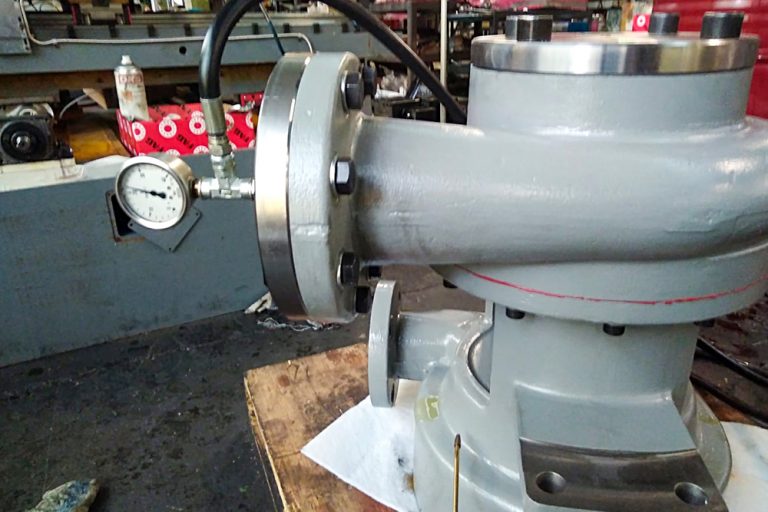

We also perform precision machining on components for hydraulic presses, cylinders and actuators.

We work parts for this specific sector, such as carbon moulds.

We are able to produce small batches of components for small, medium and large valves.

Machinery 1

Machinery 2

Machinery 3

Machinery 4

Machinery 5

Machinery 6

Machinery 7

Machinery 8

Za Ber - Officina Meccanica is equipped with more than 300 measuring instruments. Za-ber also uses the mLeika AT400 laser dimensional sensor

All staff are trained to comply with ISO 9001.