| Top machining |

Turning, Assembly, Milling, Pret-a-porter products, Superfinishing

|

|---|---|

| Max turning |

Max turning 80 from bar, 250 from recovery, max turning length 1000mm

|

| Max milling |

Max milling 800x500

|

| Other processes |

Polishing, automatic warehouse, sandblasting

|

| Operating sectors |

Food, Furnishings, Energy, Plastic processing industry, Micromechanics, Other sectors

|

| Work area | 2000 m² |

| Employees | 16 |

| Metals/Materials |

Steel, Special Steel, Aluminum, Aluminum alloys, Bronze, Iron, Brass, Copper, PVC, POM, Nylon

|

| Favorite lots |

Large lots, Periodic series, Medium series 500/1000/2000/10000

|

| Certifications |

UNI EN ISO 9001: 2015

|

Vitiesse srl was founded with the specific intention of creating a coordination pole for our production units. Primary objectives were the rationalization of resources and the integration of the experiences and potential at our disposal.

We think we have done much more, coming to combine specialization and professionalism with innovation, providing a dynamic and flexible structure, capable of rationally managing the various production, technical and administrative departments.

THEIndustry 4.0 it is the present.

Integration of Automation, Software and Cutting-edge Technology allow us to be a Smart Factory.

Continuous process control represents the future of manufacturing, thanks to integrated digital solutions that minimize risks and maximize productivity.

An innovative automatic warehouse is the heart not only of logistic flows but of all our business. Within Vitiesse we have made precision our mission, integrating an automation solution that is now at the center, even physically and not only figuratively, of all our activities.

The concept of quality is one of the cornerstones of Vitiesse. We continuously invest in people and means to make our management and control systems ever safer and more reliable.

The first quality certification was obtained in 1999 according to UNI EN ISO 9002: 1994.

The company currently operates in compliance with the requirements of the UNI EN ISO 9001: 2015 standard.

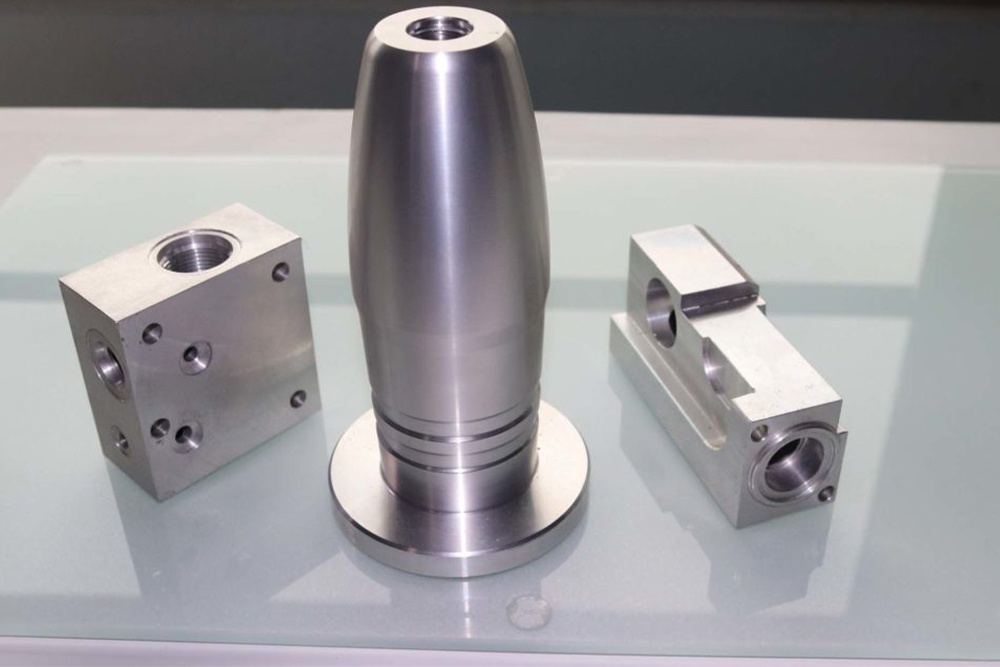

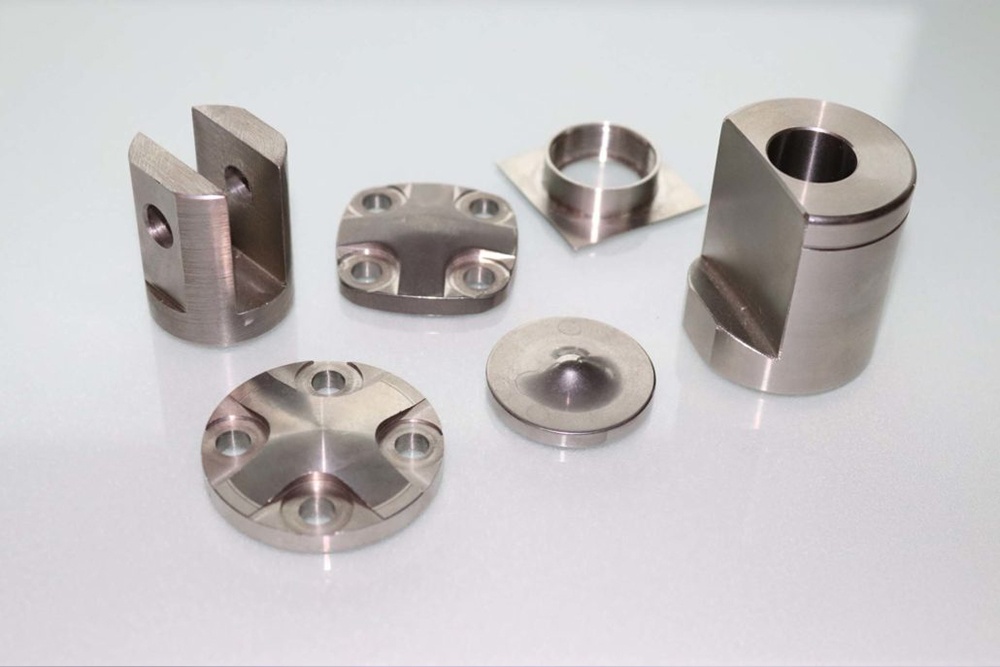

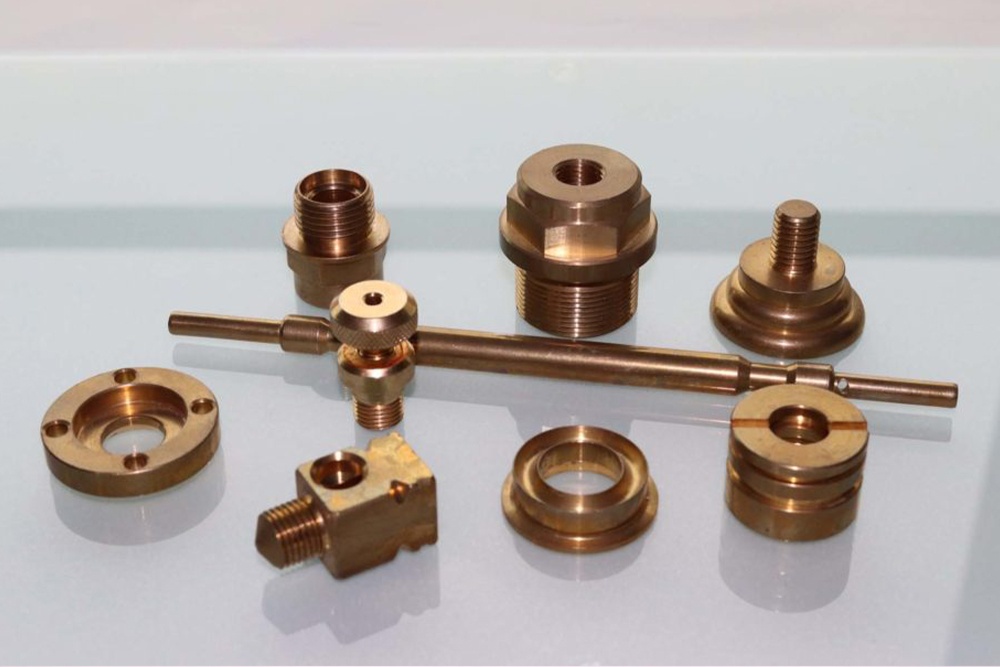

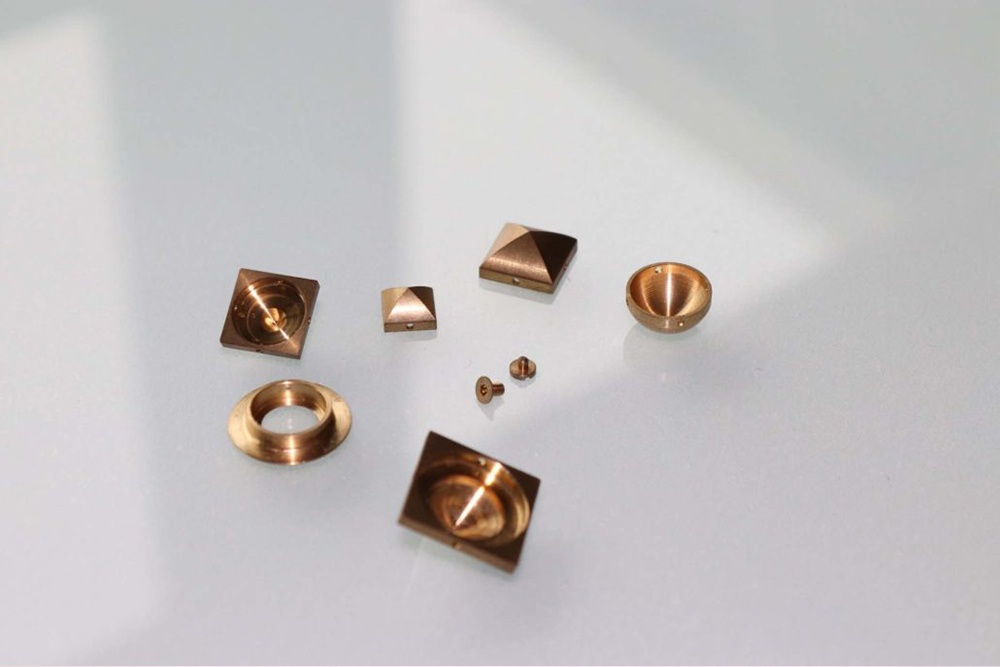

Various Products

Various Products

Various Products

Various Products

Various Products

Various Products

Various Products

Various Products

It is often problematic for a mechanical workshop to manage small assemblies in unsuitable environments. We are able to do this as the whole process takes place in clean and uncontaminated laboratories.

We usually work with alloyed and non-alloyed steels, stainless steels, aluminum alloys, brass and copper alloys, various types of plastic materials, castings and die-castings.

An innovative automatic warehouse is the heart not only of logistic flows but of all our business. At Vitiesse we have made precision our mission, integrating an automation solution that is now at the center, even physically and not only figuratively, of all our activities.

Our service idea pushes us to supply ready-to-use products, complete with thermal, protective, galvanic treatments, grinding, welding, assembly, gaskets, anti-unscrewing treatments and anything else required.

We actively participate in the technical and logistical choices of our customers, managing warehouse and just in time delivery programs, providing pre-assembled groups, packaged kits and specific preparations on request.

We are able to finish the details with tumbling treatments, micro shot peening, post grinding treatments, anti oxidation dewatering.

We have always believed in innovation and high technology, an indispensable condition for being competitive in an increasingly selective and demanding market.

We can produce turned parts from bar up to diameter 80 and on spindle up to diameter 500 in small, medium and large series with automatic single, multi-spindle and CNC machines, complete with drilling, threading and milling.

We produce components of small, medium, large dimensions that meet the demands of the agricultural sector, always keeping in mind the efficiency and resistance of the materials used.

We perform precision machining and manufacture of metal parts, based on customer specifications, also for the food sector.

We produce metal parts for all furnishing sectors.

We produce ready-to-use products, complete with surface treatments, grinding, welding, assemblies, gaskets, anti-loosening treatments for the automotive sector.

We manufacture small, medium and large components for the energy sector.

We carry out precision machining for the plastic processing industry.

We carry out precision machining and supply products complete with protective treatments, assemblies and so on, for the glass processing industry.

We offer ready-to-use products, complete with thermal, protective, galvanic treatments, grinding, welding, assembly, gaskets, anti-loosening treatments designed for the mechanical sector.

We produce metal components and parts to meet the needs of the medical sector, always keeping in mind the functionality and quality of the materials.

We perform precision machining and manufacture of metal parts, based on customer specifications, also in the micromechanics sector.

We produce small, medium and large parts for the earthmoving sector.

We work components for hydraulic presses, cylinders and actuators.

Machine name:

SOLVENT-BASED VACUUM CLEANING SYSTEM

Specifications:

Recent purchase by our company: it is a vacuum washing system that allows you to degrease, clean and dry every type of detail perfectly, even in the presence of complex geometries, blind and capillary holes. The use of vacuum guarantees the hermetic seal of the system and the absence of any residue on the pieces. Furthermore, this new technology makes it possible to drastically reduce production times and the consumption of washing liquid compared to atmospheric cycle washing machines.

The concept of quality is one of the cornerstones of Vitiesse. We continuously invest in people and means to make our management and control systems ever safer and more reliable.

The first quality certification was obtained in 1999 according to UNI EN ISO 9002: 1994.

The company currently operates in compliance with the requirements of the UNI EN ISO 9001: 2015 standard.