| Top machining |

Assembly, Calendering, Carpentry, Bending, Wire Bending, Pipe Bending, Welding, Robotic Welding, Deburring, Cutting

|

|---|---|

| Other processes |

Threading, Drilling, Polishing, Tapping

|

| Operating sectors |

Agricultural, food, ventilation, furnishings, sports equipment, automotive, construction, energy, railways, hobby, plant engineering, cycling industry, tensile structures, other sectors...

|

| Work area | 2000 m² |

| Employees | 14 |

| Metals/Materials |

Steel, stainless steel, iron, copper, aluminium

|

VAS has been present on the market since 1992, in the furniture sector with iron and aluminum components for the home, office, community spaces, conference rooms and theatres.

Thanks to the purchase, in 2011, of a CNC wire bending machine, built specifically for the production needs of our company, we are able to work both metal wire that the saucer.

The incredible versatility of this machine therefore allows us to reduce production costs, concentrating the operational steps in a single process (bending, threading, drilling, shearing, etc…)

Upon completion, we also perform some ancillary processes at the request of the customer and once the production is finished we carry out the final check. The goods are then prepared for shipment using thepackaging suitable for shipping, optimizing spaces and volumes.

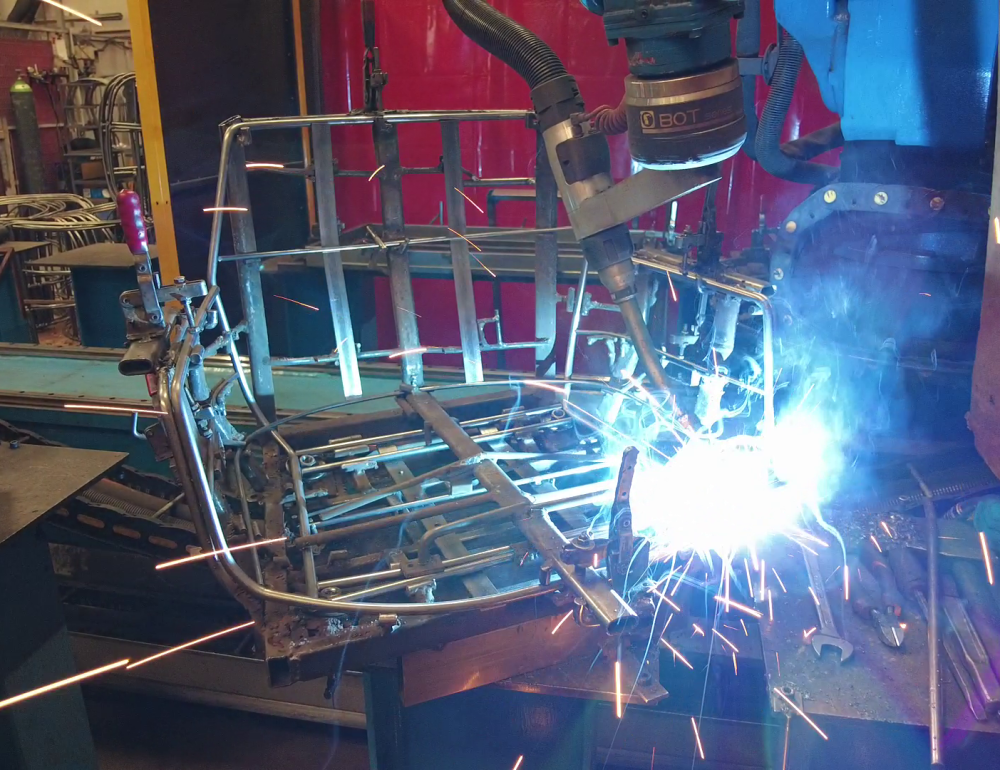

Product: Backrest insert for flexible foam

Description: example of armchair backrest insert for flexible foam, office and home use, with CNC drilled and threaded plates, assembled by robot welding.

Processing: drilling / threading / robotic welding

Product: carpentry details

Description: example of different types of materials and CNC machining, with the possibility of drilling/threading from M6 and M8 at the same time with the possibility of moving in Z and X axis and in different positions of the width of the plate (max. 25mm.)

Processing: drilling / threading

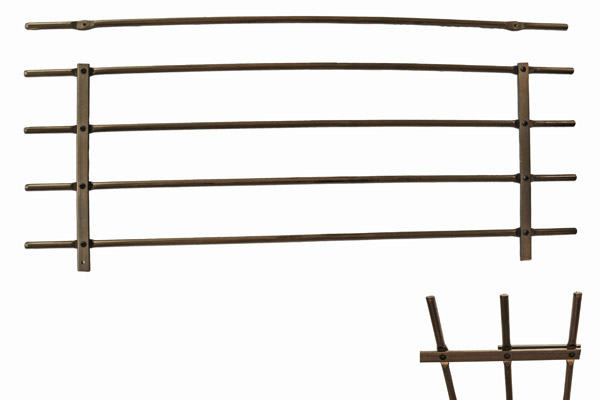

Product: fence components

Description: example of detail for fencing with customized modules according to needs in rod d.12, flattened, drilled, threaded all in a single CNC step.

Processing: drilling / tapping / bending

Product: home accessories

Description: example of non-welded pipe in galvanized FE/360 various lengths, with relative plastic supports to be inserted in the wooden panel.

Product: table ice bucket holder

Description: example of accessory for bar/restaurant/trattoria/winery cellar, in d.10 rod painted with epoxy powder in various colours.

In technical language, the complex of operations necessary to put together the various pre-made parts of a device, a product, and the like (it is also called, less often, assembly).

In VAS srl we assemble parts for the construction of structures and inserts for backrests, footrest ring inserts, etc.

Thanks to the presence of a complete fleet of machines and highly qualified operators, we are able to carry out various processes such as: calendering, threading, drilling, cutting, shearing, welding, bending and bending operations.

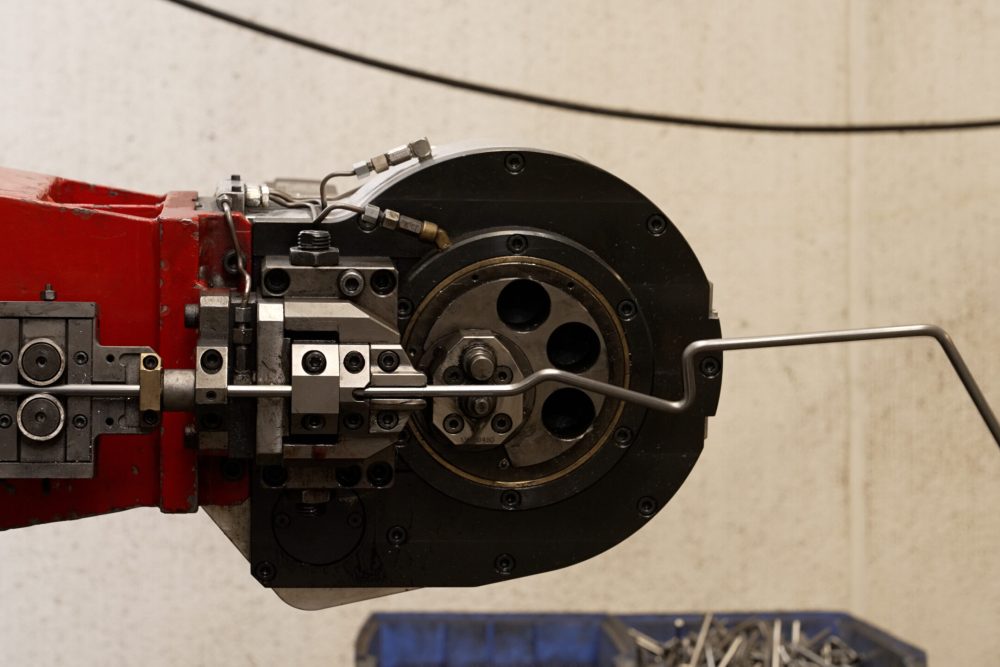

A strong point within our production is given by the presence of a CNC wire bending machine in the carpentry department, built specifically to meet the company's production needs. In fact, the wire bending machine allows us to work metal wires of different diameters more quickly, reducing production times.

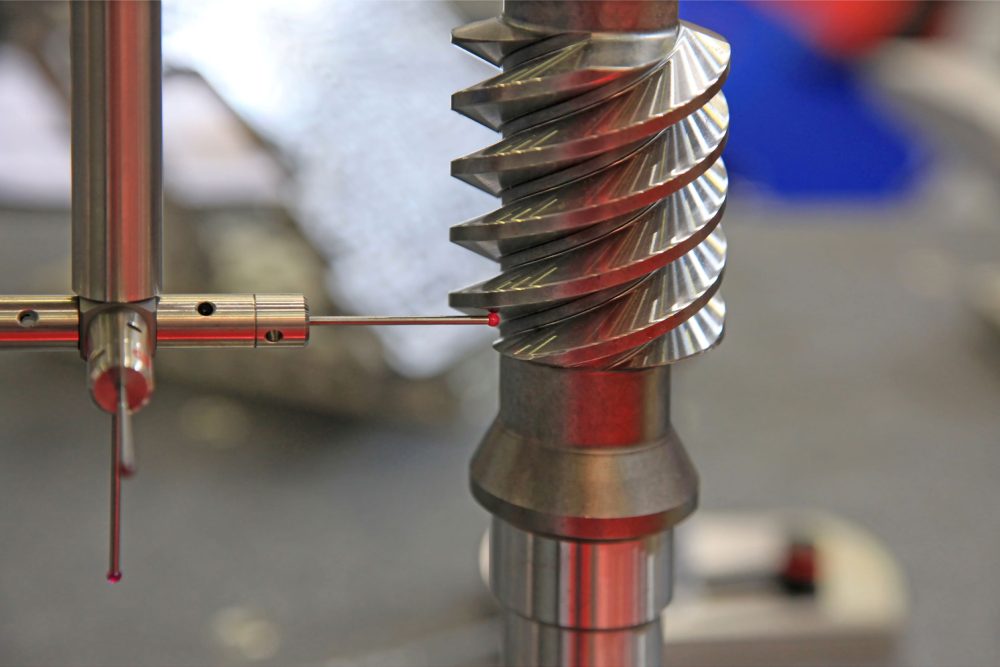

We can work different types of materials and perform various CNC machining, with the possibility of drilling/threading from M6 and M8 at the same time, with the possibility of moving in the Z and X axis and in different positions of the width of the plate (max. 25mm).

We carry out machining on different types of parts, with the possibility of inserting holes/threads in any position, always in a single CNC step.

The term polishing (or polishing or polishing if it refers to gems) means the process implemented to make the surface of an object shiny, so that the body in question shines with reflected light.

At VAS we carry out the polishing of the components intended for assembly.

VAS also boasts expertise in the field of tapping, thanks to the presence of advanced machinery and highly qualified personnel.

Metal bending is used to bend sheet metal by providing it with an angle that varies according to production requirements.

Our company carries out this type of processing on metals such as steel and iron and intervenes on thicknesses that can reach up to 10 millimetres, creating very wide bending angles.

The precision in the execution of the tube bending is guaranteed by the use of bending machines, the introduction of which allows not only the considerable speeding up of the times, but also the extreme precision of the final result.

We are equipped with advanced equipment and operators who have been specialized for several years in welding processes, in order to be able to offer internally, and without recourse to subcontractors, any type of process that requires welding operations.

Two robotic islands allow us to combine speed and precision.

In fact, our welding robots are equipped with a two-station table changer with double lathe, to work bulkier items, and five work stations, for much more manageable items.

Even for deburring we count on the expertise of specialized operators, who allow us to offer internally any type of processing that requires deburring operations.

For the realization of any piece we start from the prototyping to get to the engineering and final production of unique components.

The first phase of each process involves distinct material cutting processes.

Why choose us?

Why we are committed to go beyond the limits of simple processing.

We believe that beauty of an object is given by the beauty of the quality and precision of each one detail and component, that's why we assist well-known designers to make complements furniture solid and elegant.

In addition, asingle bending process of the wire results in a saving of money for ours clients: because we produce less waste and therefore we use less material, we use a single machine for bending the metal wire and we don't have to constantly pick up the semi-finished products.

Machine name:

CNC wire bending machine

Specifications:

In 2011 we purchased a CNC wire bending machine, built specifically to meet the company's production needs. The machine is used both for working the wire (from 8 up to 15 mm in diameter) and for working the strip (from size 15 with a thickness of 2 mm up to size 25 with a thickness of 5 mm).

The presence of highly qualified personnel and cutting-edge machinery have ensured that VAS snc become a modern, serious and reliable company, a valid aid for all those manufacturing companies which need to satisfy specific production standards in an increasingly eclectic and diversified market.

The simplification of production processes in wire bending allows us to offer an even more effective and punctual assistance service, in which attention to the customer always plays a fundamental role.