| Top machining |

Milling, CNC Milling, Turning, CNC Turning, Sheet Metal Cutting, Prototyping, Carpentry

|

|---|---|

| Max turning |

Max turning øD 2000x2000

|

| Max milling |

Max milling 2000x6000

|

| Other processes |

Welding, Assembly, Bending, Drilling, Laser Cutting

|

| Operating sectors |

Food,, Energy, Pharmaceutical, Industrial, Medical

|

| Work area | 2500 m² |

| Employees | 32 |

| Metals/Materials |

Steel, special steel, aluminum, aluminum alloys, bronze, iron, brass, copper

|

| Favorite lots |

Small series, periodic series

|

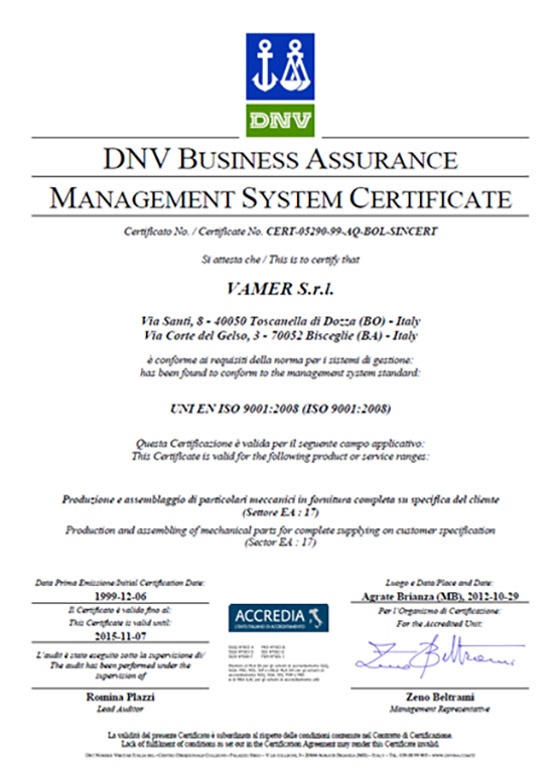

| Certifications |

ISO 9001: 2015

|

Present on the market since 1979, Vamer has gained forty years of experience in the mechanical processing sector, strengthening its skills over time and distinguishing itself for punctuality and quality.

Vamer specializes in the supply of complex and high-precision components, with unit quantities or small series, formats for automatic machines, machine groups and / or complete assembly systems, with sales management as prime contractor.

The company is able to guarantee a spare parts service within 48 hours for each sector, thanks to the use of its own means of transport.

Product 1

Product 2

Product 3

Product 4

Product 5

Product 6

Product 7

Product 8

Product 9

Product 10

Product 11

Product 12

In the video it is possible to view an example of execution of an assembly of a turnkey automatic machine.

Here, our technicians deal with the assembly of turnkey sorting machines.

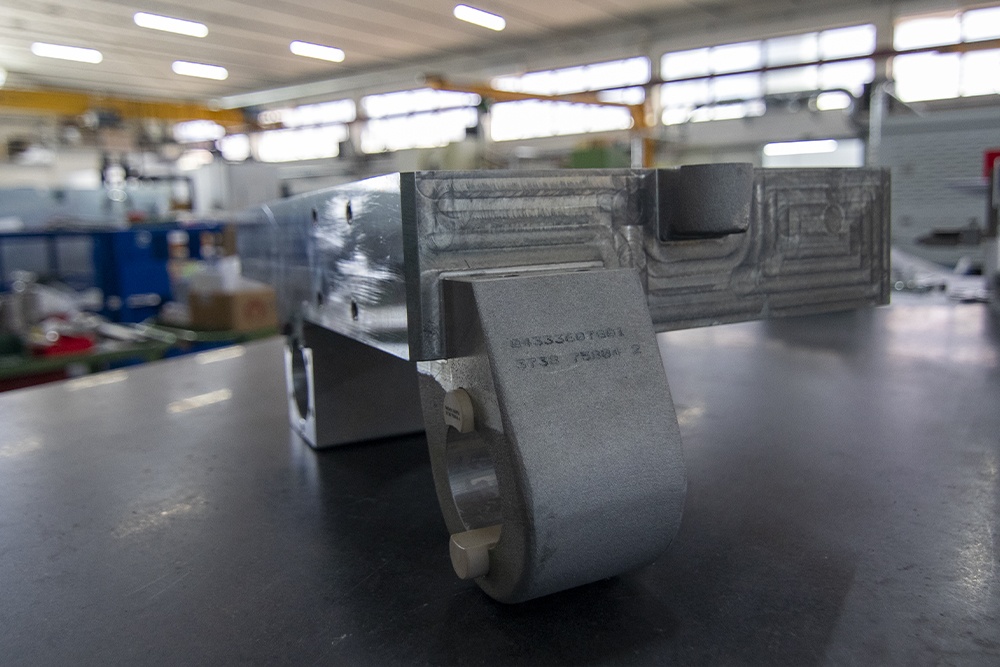

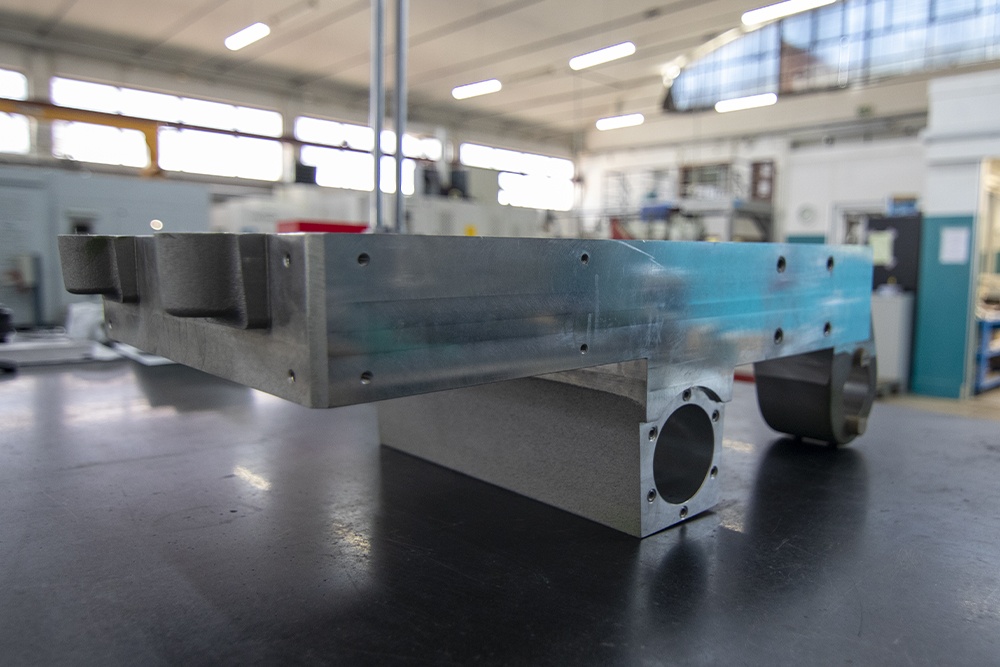

We carry out various carpentry works. Here is an example of a welded, normalized and galvanized SJ235 base.

We are able to make deep holes up to a diameter of 80X2000.

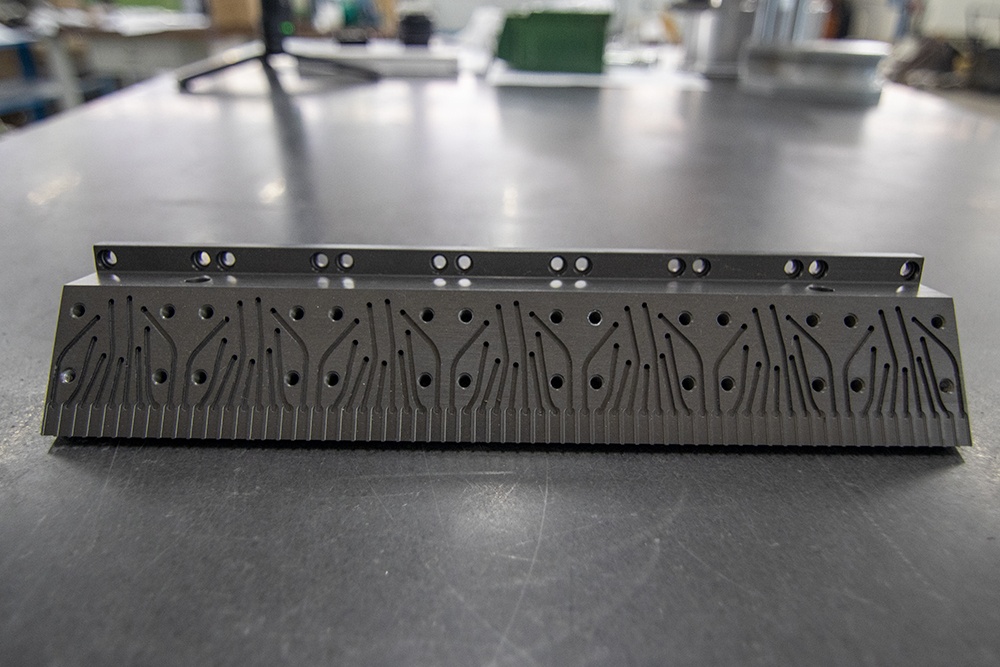

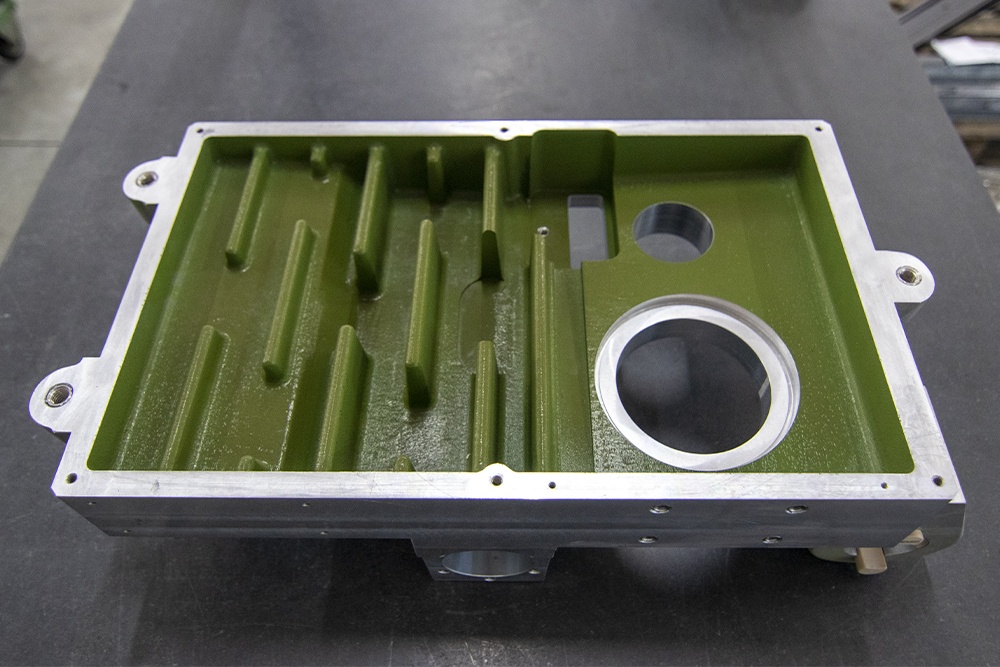

We carry out 5-AXIS milling/boring operations with internal cam execution.

We carry out laser marking of all components to identify the production batch and traceability of the components produced.

Our machines allow us to carry out bending operations of 3000 X 175 TON 6 CNC axes.

N 3 automatic cutting lines DIA 400, department equipped with a barcode system for the identification and traceability of materials.

We are able to perform 2000×4000, 4000 Watt laser cutting operations.

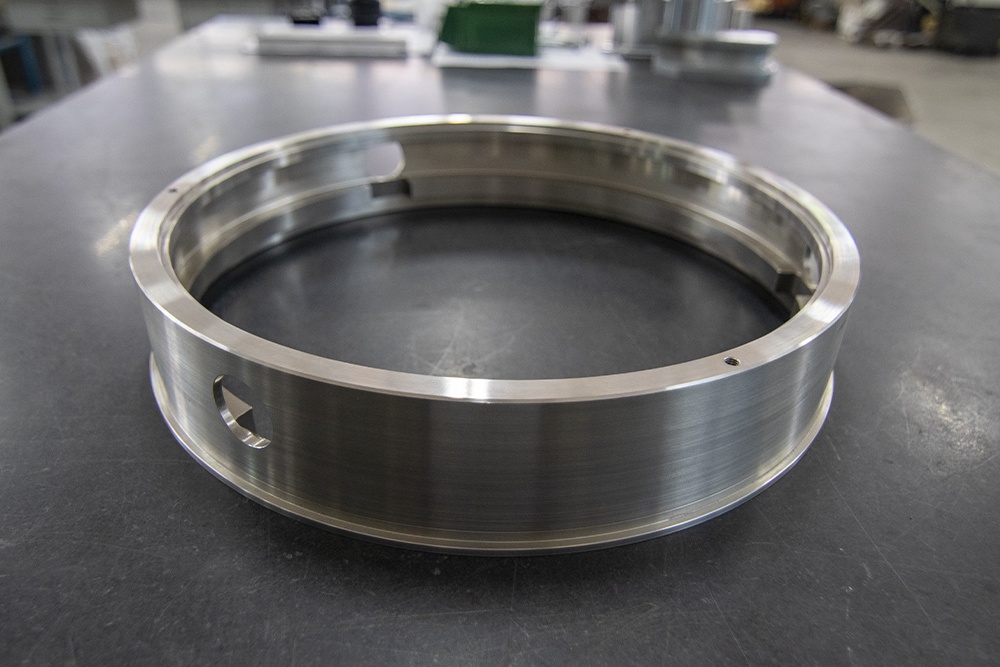

We carry out CNC turning up to DIA 700X1500 with motorized and Y axis, series turning with motorized automatic loader, counter spindle and Y axis, CNC vertical turning 2000X2000.

Our processes are intended for various sectors, including the food sector. Here is an example of a food column.

We deal with the processing and production of wind turbines up to 100 kW.

For the pharmaceutical sector production of groups and conveyor belts.

In addition to the pharmaceutical sector, our production is also aimed at the medical sector for which we produce medical components and assemblies.

We also deal with the construction of components for special vehicles. In particular of platforms and ladders for firefighters.

The cutting department is equipped with a scanner for reading the bar code in order to guarantee the traceability of the material used

The department is able to supply high precision parts in single quantities, especially spare parts.

The department is able to produce high precision parts with small-medium series production

The department is equipped to produce high precision parts, in single quantities, especially spare parts.

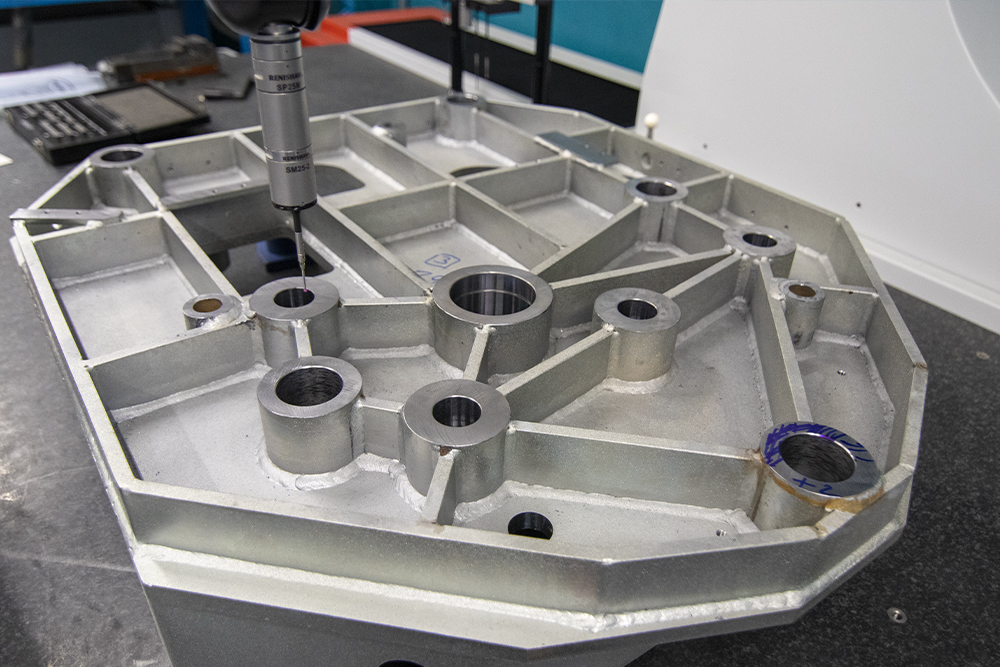

The department is able to produce parts of high precision and complexity, both in unit quantities and in small and medium series.

The department is able to produce all types of parts, in stainless steel - aluminum

The department is able to satisfy any customer need, including plant engineering.

These equipments allow Vamer to be autonomous in processing and able to satisfy requests for deliveries in 48 hours, thanks to the use of its own means of transport.

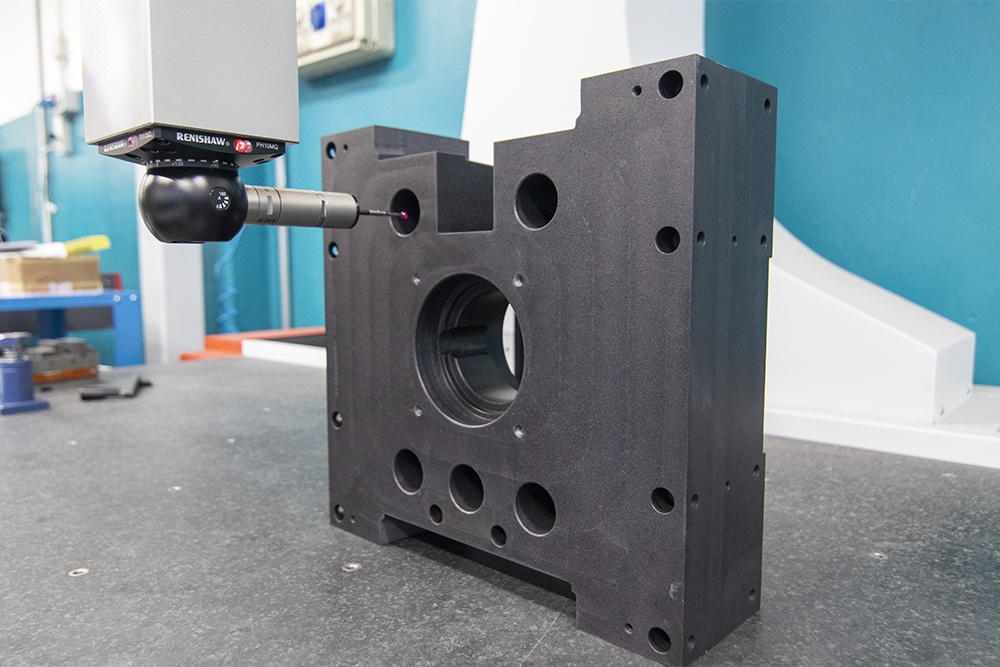

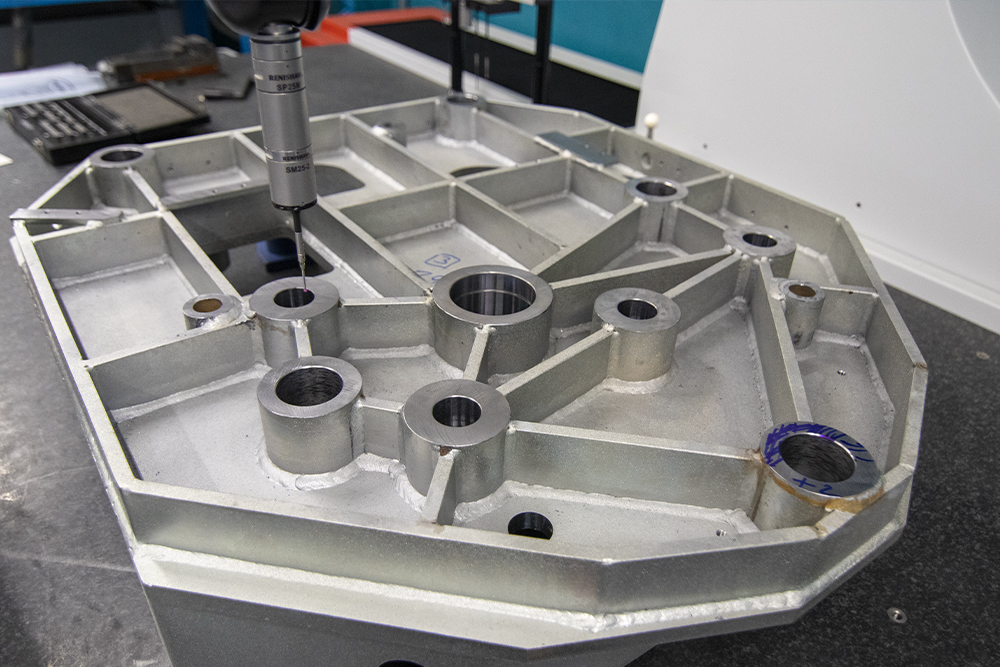

Control during the process and at the end of the process with certificate release upon request

Altimeters - micrometers - 3d cnc measuring machines 1000x1000x1500 with continuous scanning and printing of test report - tar-al for instrument calibration - durometer.

Since 2007, Vamer has obtained ISO 9001 certification, then updated to the 2015 revision, for all production sites, certifying the following corporate purpose "Production and assembly of mechanical parts in complete supply according to customer specifications (EA 17)".

In vamer, particular attention is paid to personnel safety and the environment. The departments are all equipped with air-conditioning and air-conditioning systems. In addition, an 80 KW photovoltaic system was installed to ensure the greatest possible autonomy.