| Top machining |

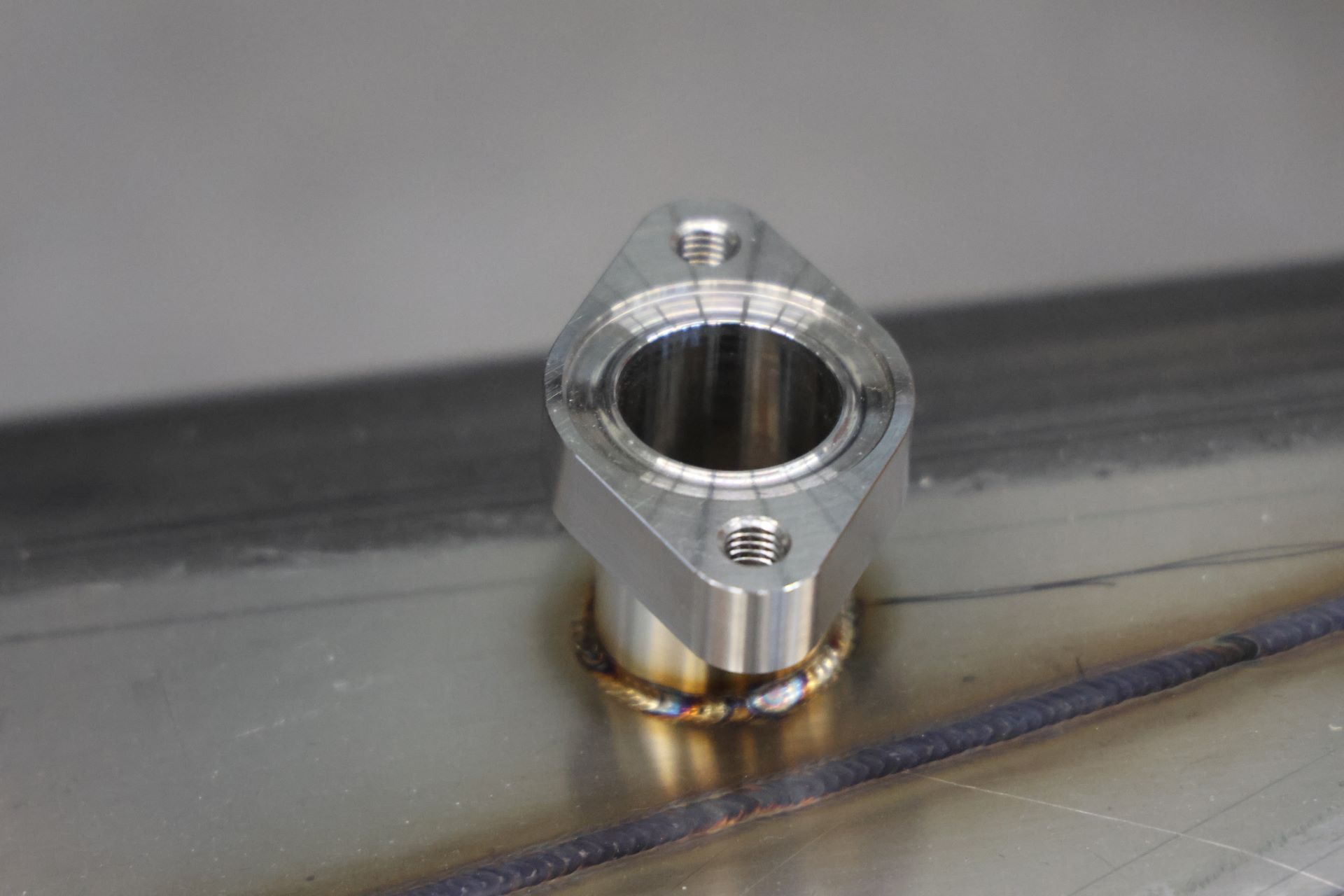

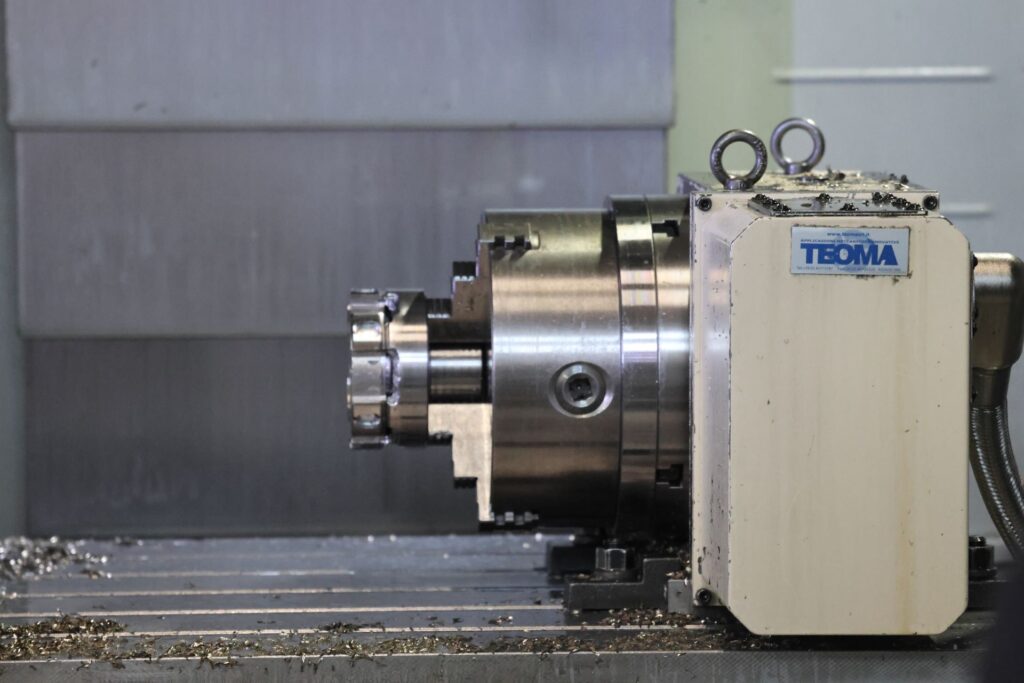

Turning, Milling, Welding, Bending, Surface Treatments, Assembly, Laser Marking

|

|---|---|

| MAX. turning |

Ø400

|

| MAX. milling |

1300X600X400

|

| Services |

Testing, complete supply of carpentry, CAM programming, logistics, warehouse

|

| Operating sectors |

Food, Bottling, Packaging, Conveyors, Industrial Machinery, Packaging, Other sectors...

|

| Work area | 1600 m² |

| Employees | 40 |

| Metals/Materials |

Steels, Aluminium

|

| Favorite lots |

Single piece, small series, plates, small pieces, shooting pieces

|

| Certifications |

- Welding qualifications - Visual checks - Liquid penetrant checks More info in the quality section |

Active as Firmac srl since 1990 in the manufacturing sector mechanical constructions for the food and beverage industry, we are specialized in the design, construction and assembly of components and machines for third parties.

We address system builders with a complete range of services and products: from the supply of individual parts based on drawings or designed by us, to the design and construction of modules and complete machines. Since the beginning we have worked continuously for leading and historic companies in the sector.

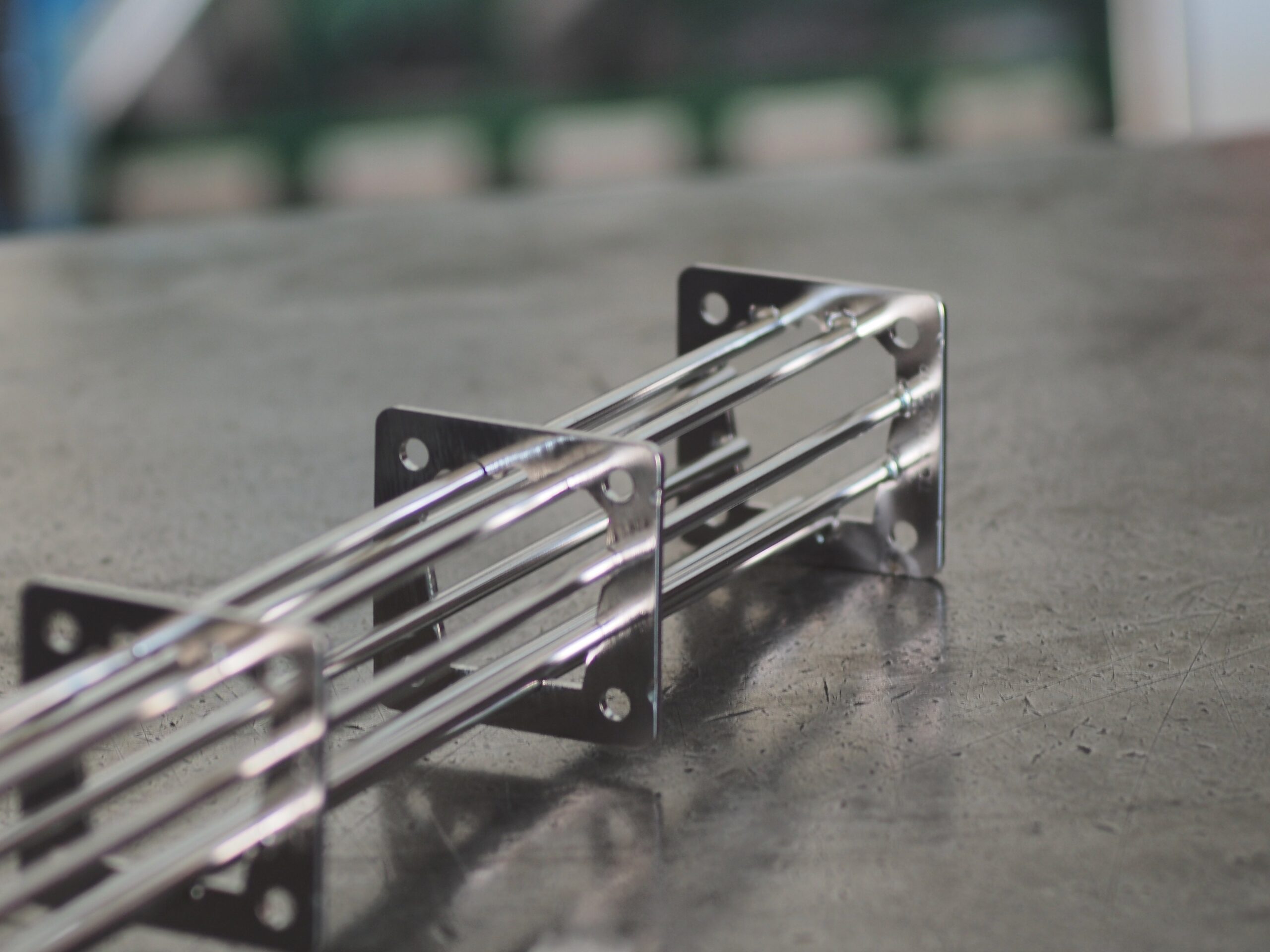

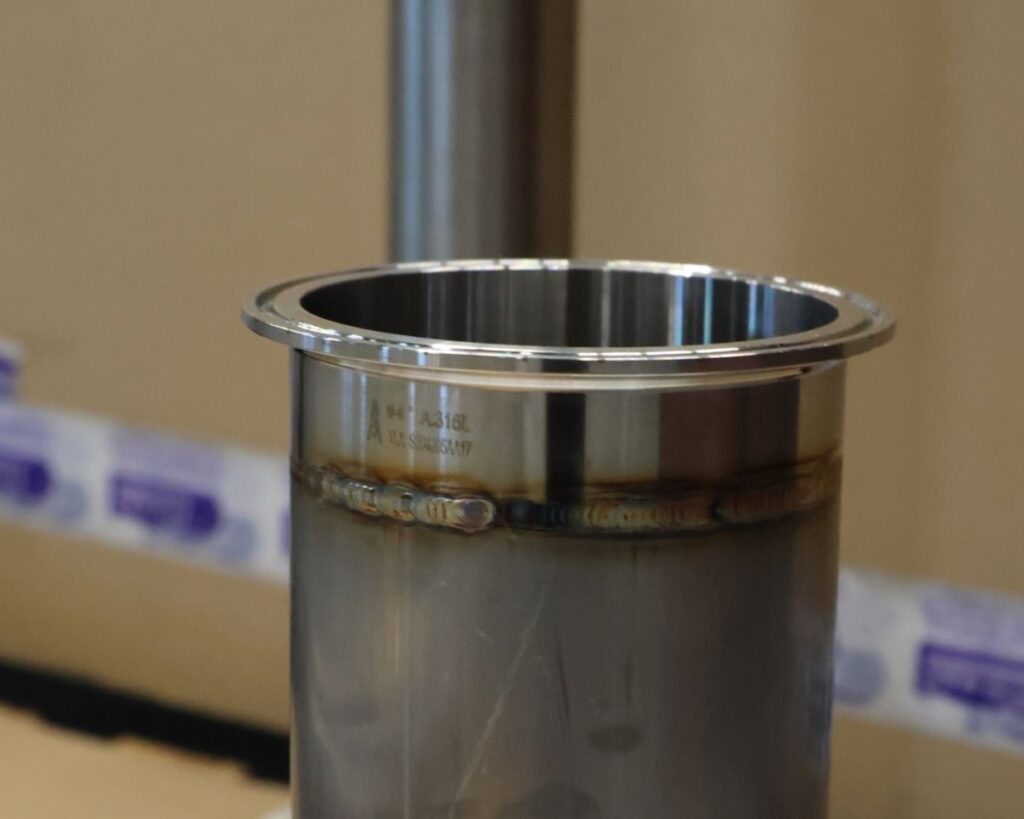

The welding processes are put into practice by welders qualified in TIG processes on stainless steel and MIG on stainless steel and carbon steel.

For more information on parts and processes, contact FIRMAC SRL

For more information on parts and processes, contact FIRMAC SRL

For more information on parts and processes, contact FIRMAC SRL

For more information on parts and processes, contact FIRMAC SRL

For more information on parts and processes, contact FIRMAC SRL

For more information on parts and processes, contact FIRMAC SRL

For more information on parts and processes, contact FIRMAC SRL

For more information on parts and processes, contact FIRMAC SRL

For more information on parts and processes, contact FIRMAC SRL

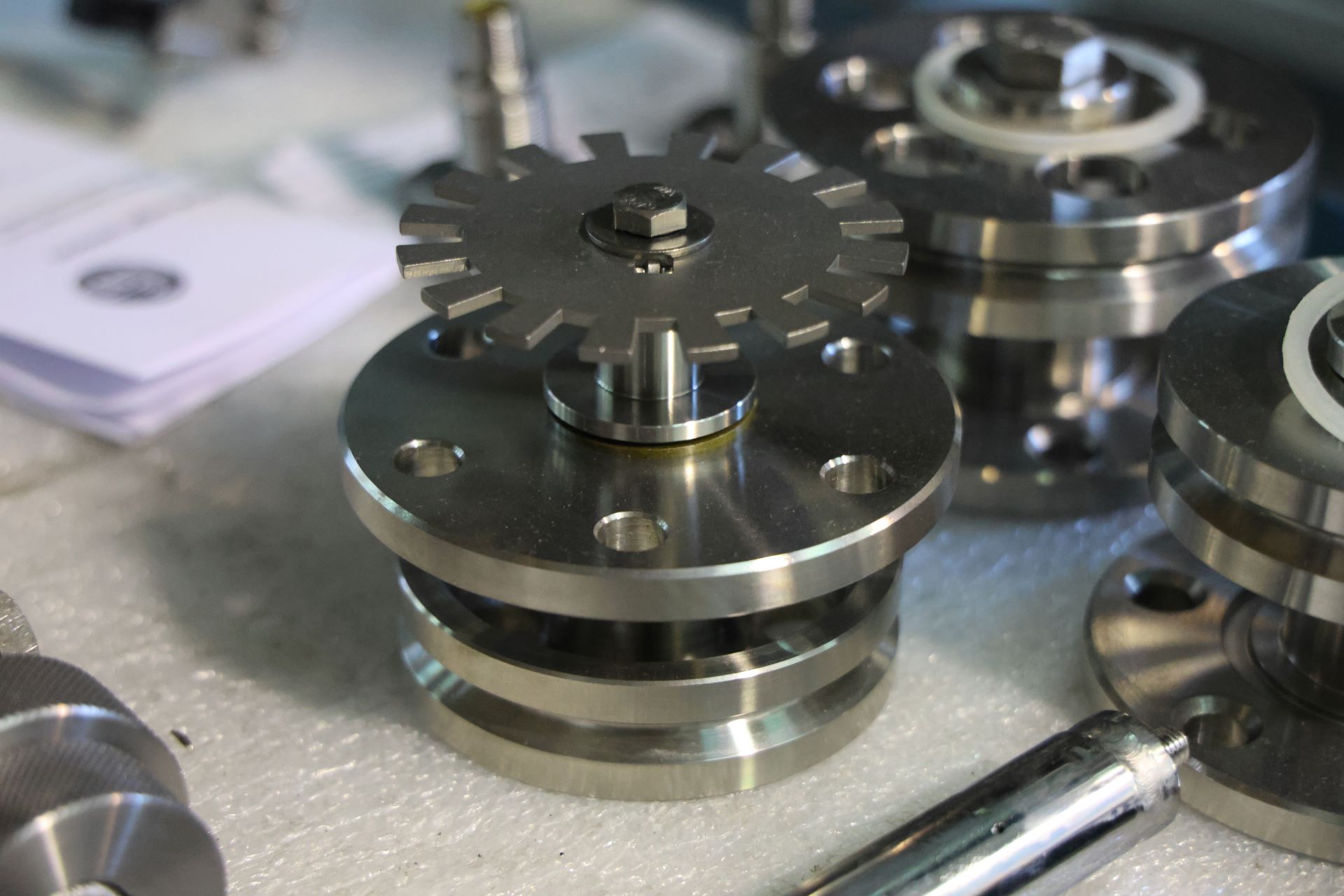

We produce small and medium-sized turned components both with parallel and CNC lathes.

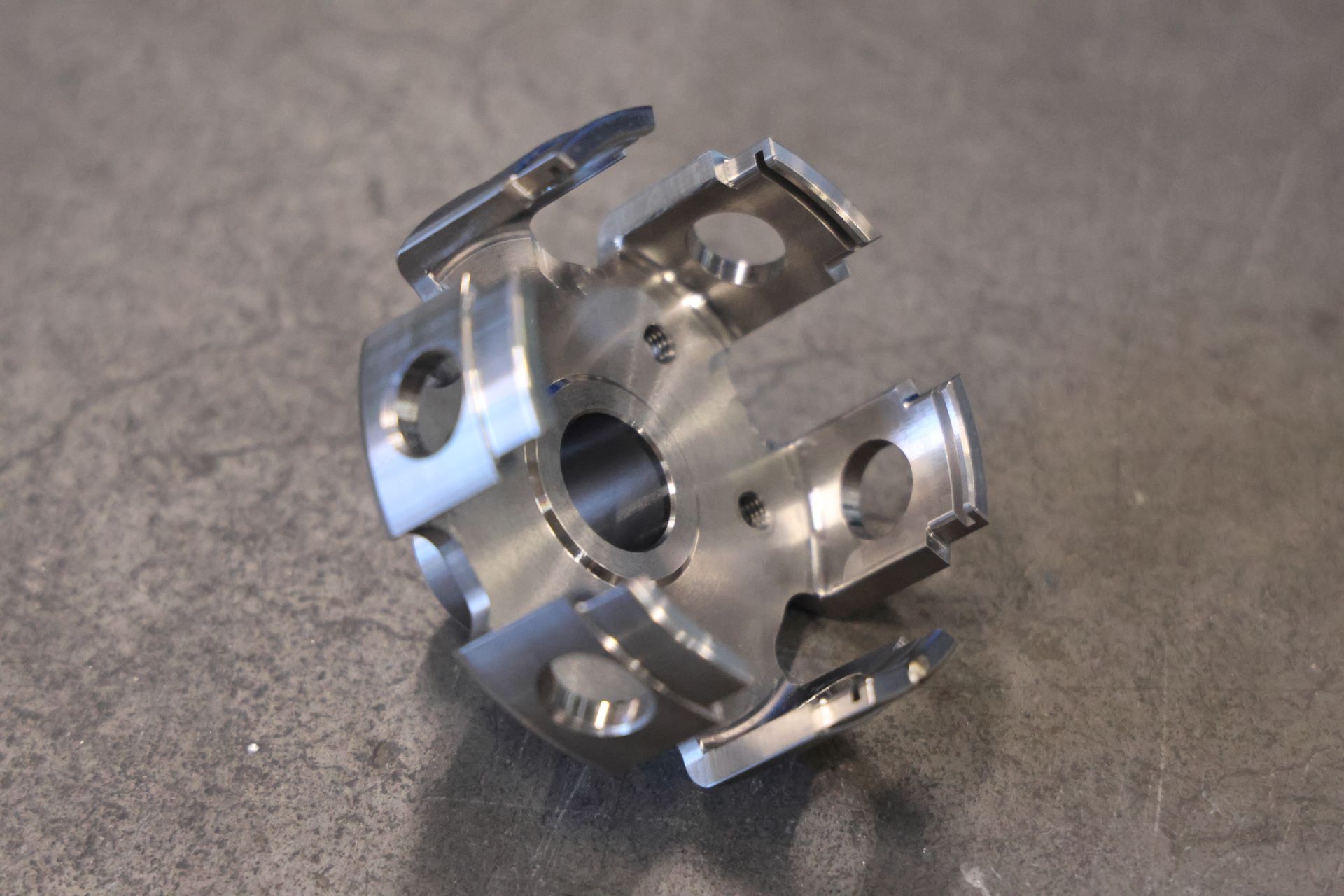

Specialized in single batches and small-medium sized batches, we are able to solve multiple removal processing needs.

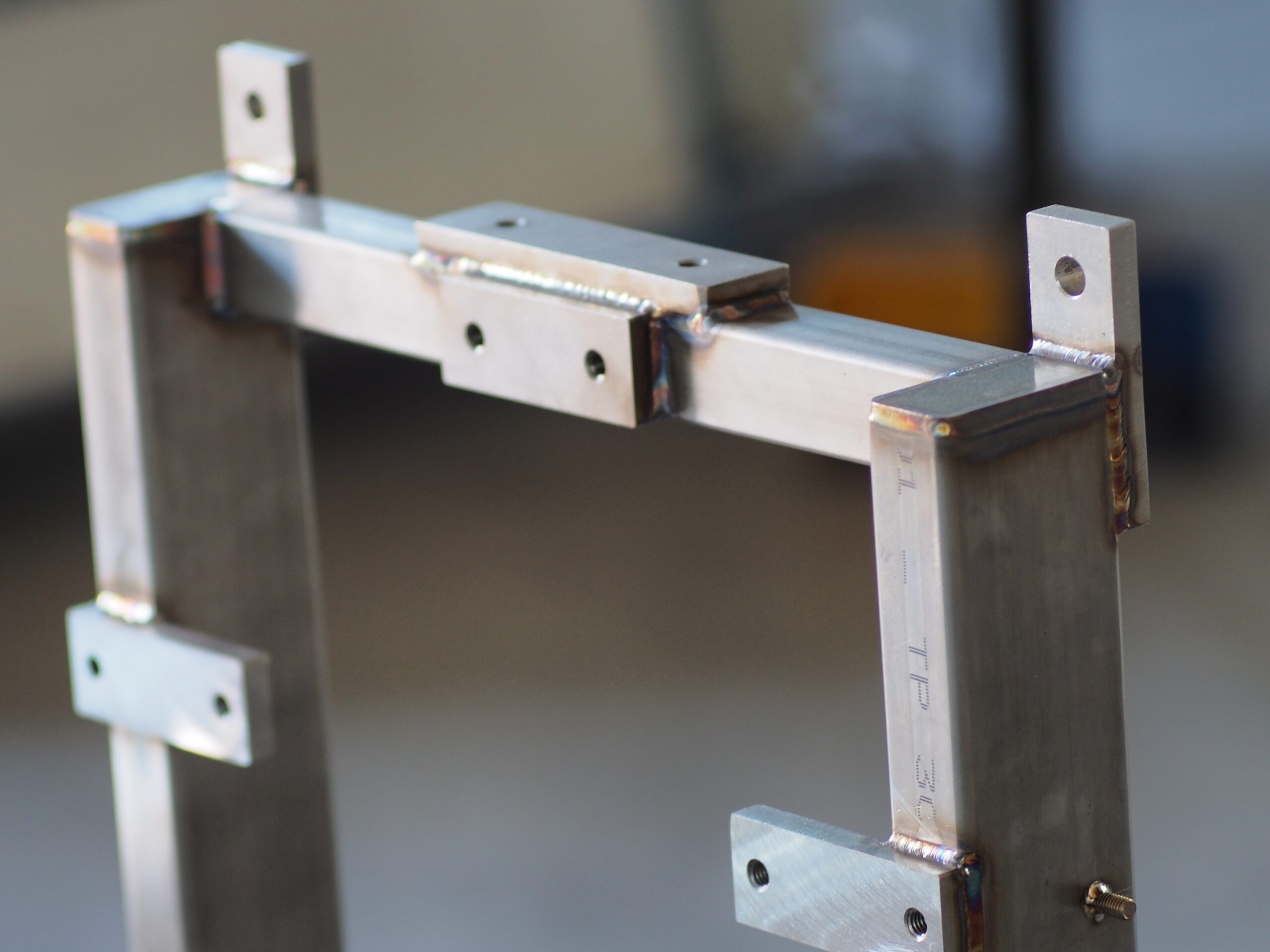

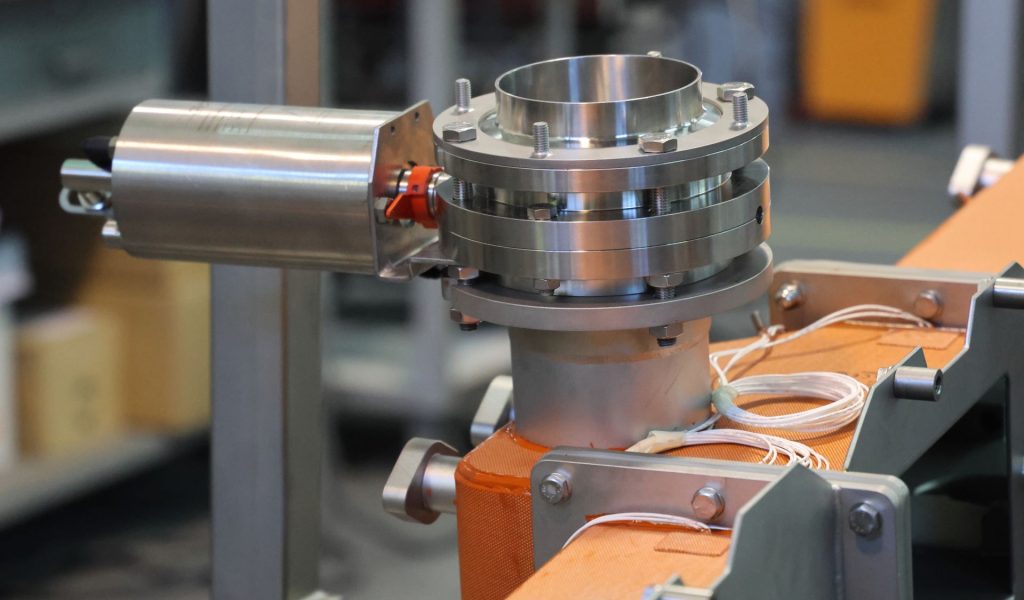

We carry out milling processes both with CNC and manual machines, with specialization in the processing of welded and stainless steel sheet products, even for single units.

Steel welding processes are carried out by qualified personnel. We create products from both sheet metal and tubular, as well as in combination with the mechanical parts made in our departments.

We are equipped with sheet metal bending stations, as well as bar cutting stations, deburring and surface finishing stations (micro shot peening, satin finishing and polishing).

We assemble machines including: fillers, rinsers, blowers, craters, decraters, palletizers, conveyor belts.

To provide the customer with the finished order, we also carry out adjustment, broaching, mold construction, marking, EDM micro-drilling, slotting, also making use of external suppliers and partners.

WHY CHOOSE US?

Our workshop is structured to have maximum autonomy in the construction of your machines. In thirty years of activity we have created a structure with a wide production range for your quality and speed needs.

We put Firmac at your quality.

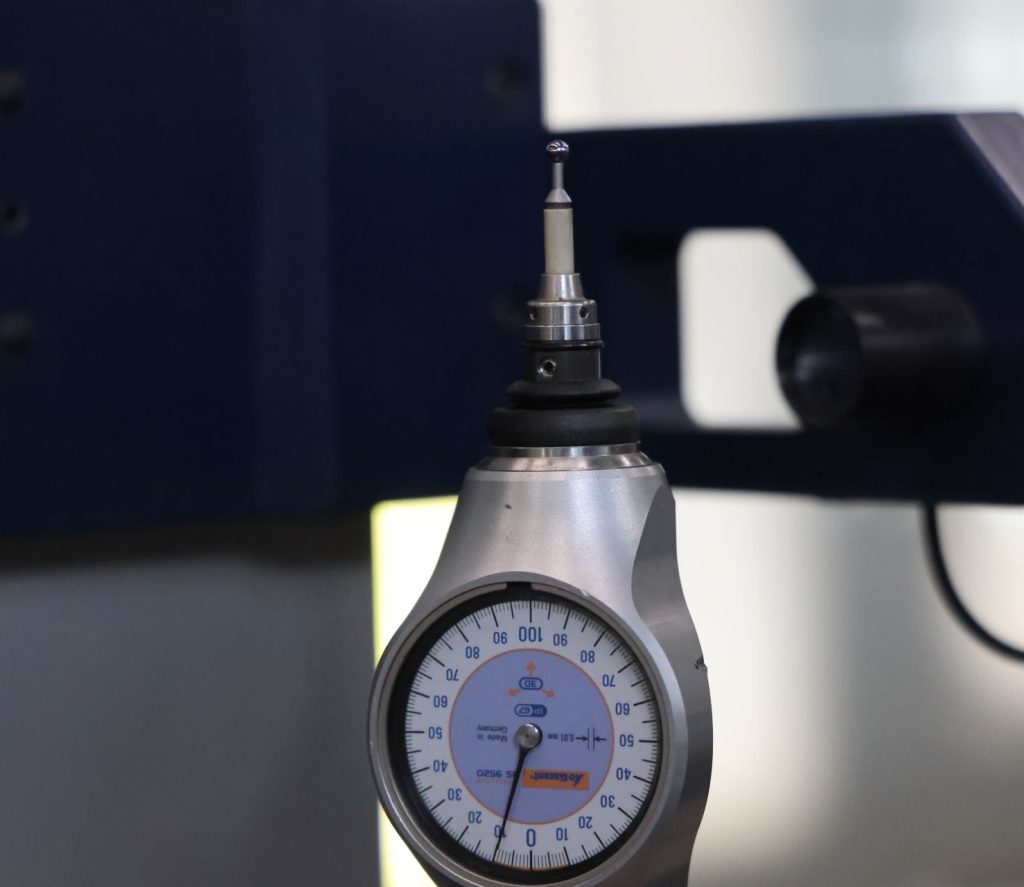

Internal dimensional controls and testing reports allow us to guarantee constant reliability of our production services.

The growth of internal production processes, from small and medium metal carpentry work to mechanical work and assembly, allows for the rapid development of projects supplied by the customer or carried out by us.

In the creation of chip removal components, the company uses CAM programming to facilitate the creation of complex geometries.

To better safeguard the materials and reduce delivery times, we have our own vehicles to manage transport to and from the customer.

Organized areas are available for the storage of semi-finished products and with the possibility of storing finished items for scheduled orders.

Our order management system is consolidated and validated from the technical-commercial analysis phase to delivery.

The constant collection of data and the continuous digitalisation of production cycles allows us to monitor the quality of the processes and take corrective actions with maximum reactivity.

Welding qualifications

Visual checks

Liquid penetrant checks