| Top machining |

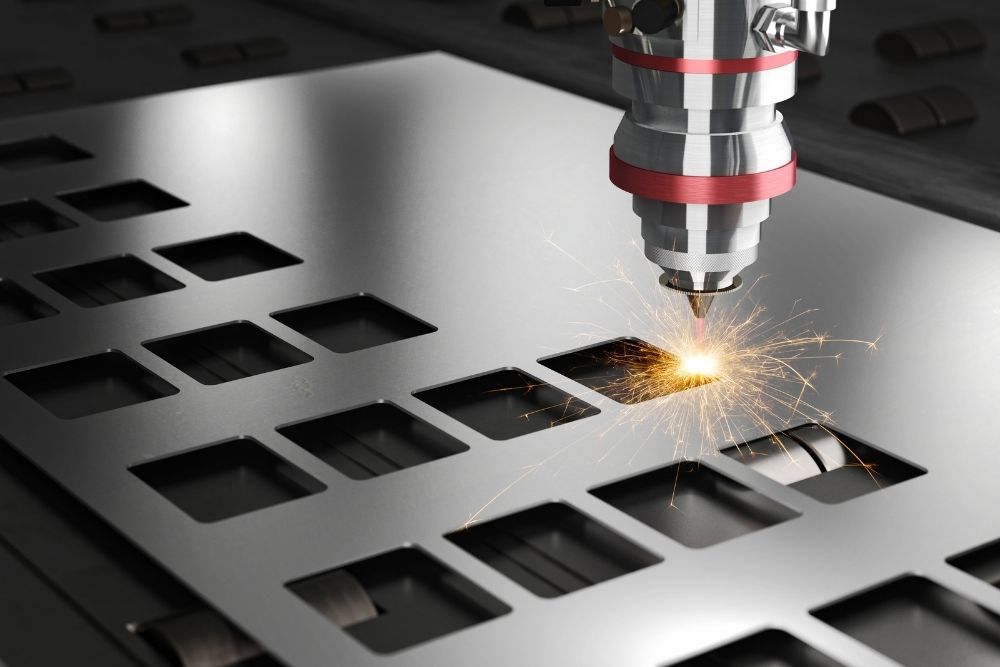

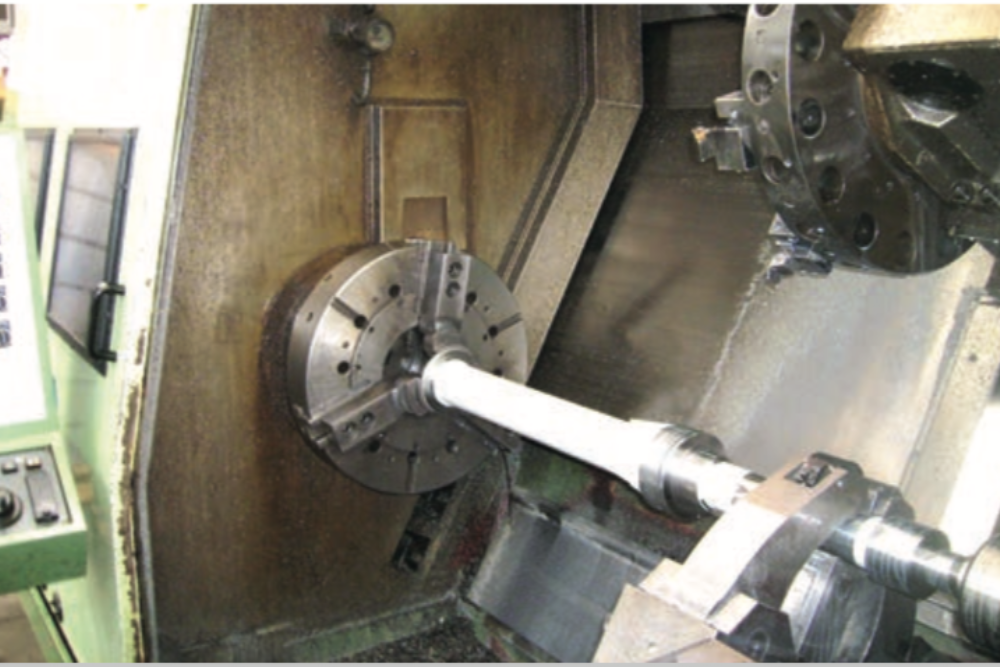

Turning, Milling, Boring

|

|---|---|

| Max turning |

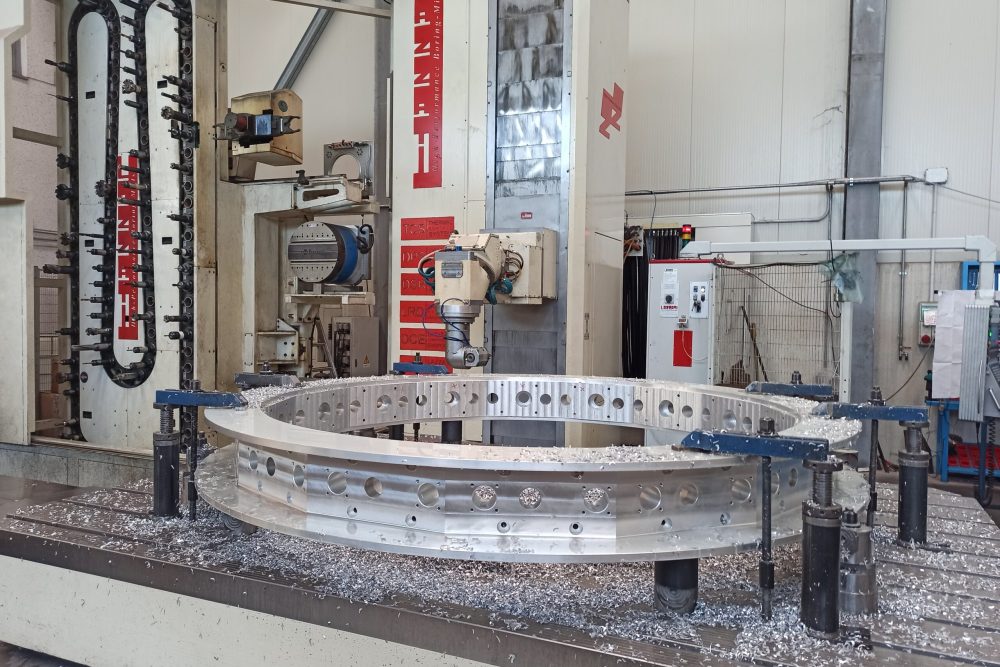

Max turning ø3300 20Ton - Turning on vertical lathes from 800 to 3200 diameter, max height 2000

|

| Max milling |

Max milling 10 m 30Ton

|

| Other processes |

Assembly, Testing, Threading, Drilling, Marking, Grinding, Sandblasting, Welding, Robotic Welding, Deburring

|

| Operating sectors |

Automation and food systems, Automation and automotive systems, Other sectors...

|

| Work area | 20 000 m² |

| Employees | 80 |

| Metals/Materials |

Steel, Special Steel, Aluminum, Aluminum Alloys, Bronze, Iron, Cast Iron, Brass, Special Metals

|

| Favorite lots |

Medium pieces, Large pieces

|

| Certifications |

ISO 9001: 2015

|

The history of the Ravera brothers in the mechanical processing sector began in 1980 with turning and milling activities on traditional machine tools.

From the continuous investments in innovative machinery, cutting-edge technologies and qualified personnel, a structure has emerged that is able to satisfy, on behalf of third parties, important industrial groups both nationally and internationally.

The primary objective of OMR is the full satisfaction of the Customer, obtained through effective and punctual strategies as required by UNI EN ISO 9001, as a seal of a policy which has always been based on Quality.

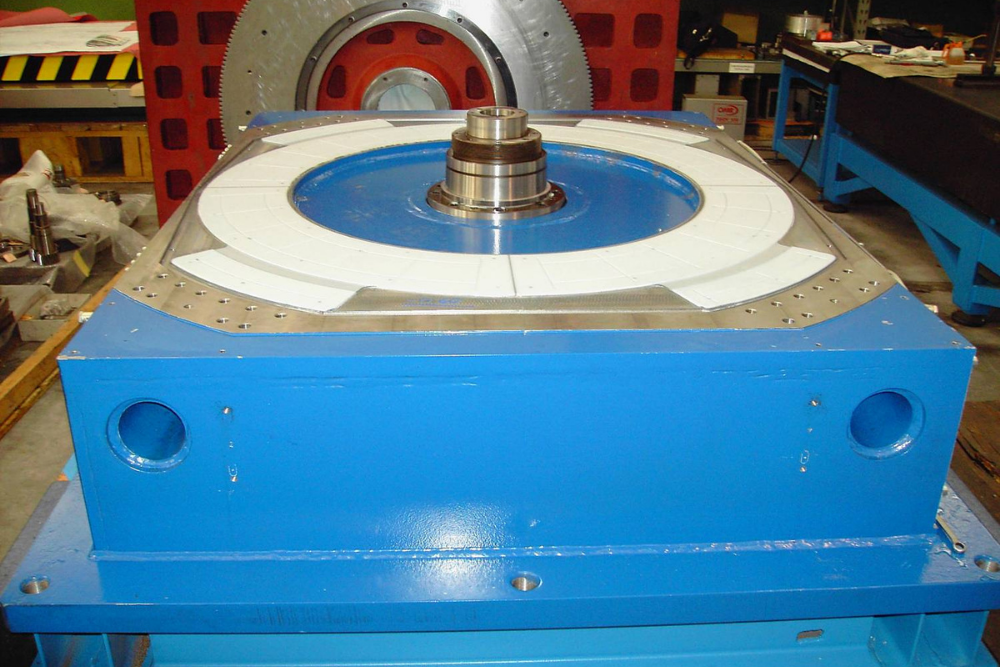

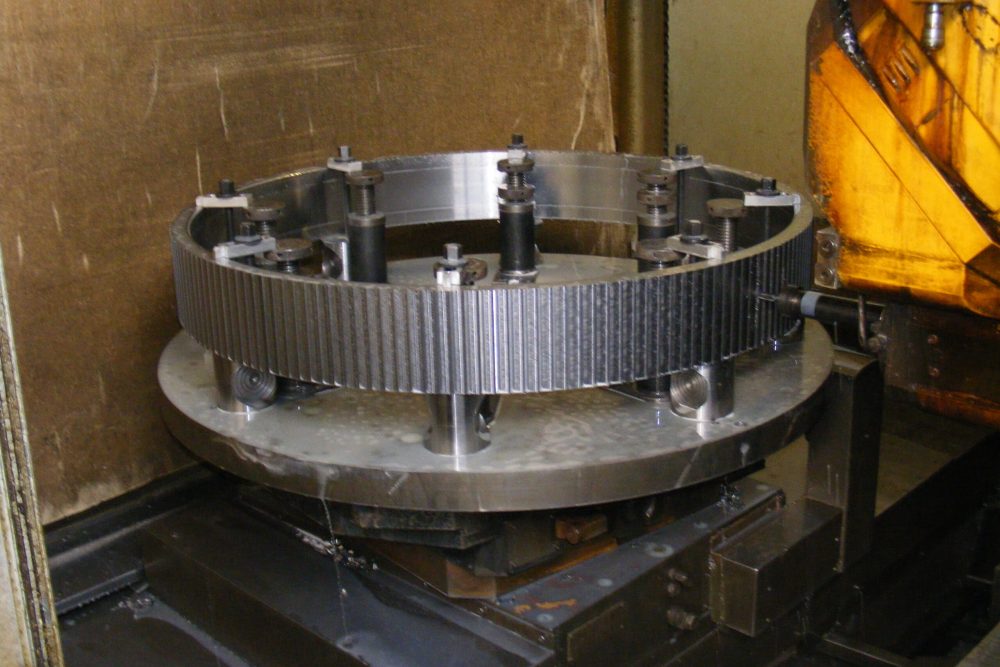

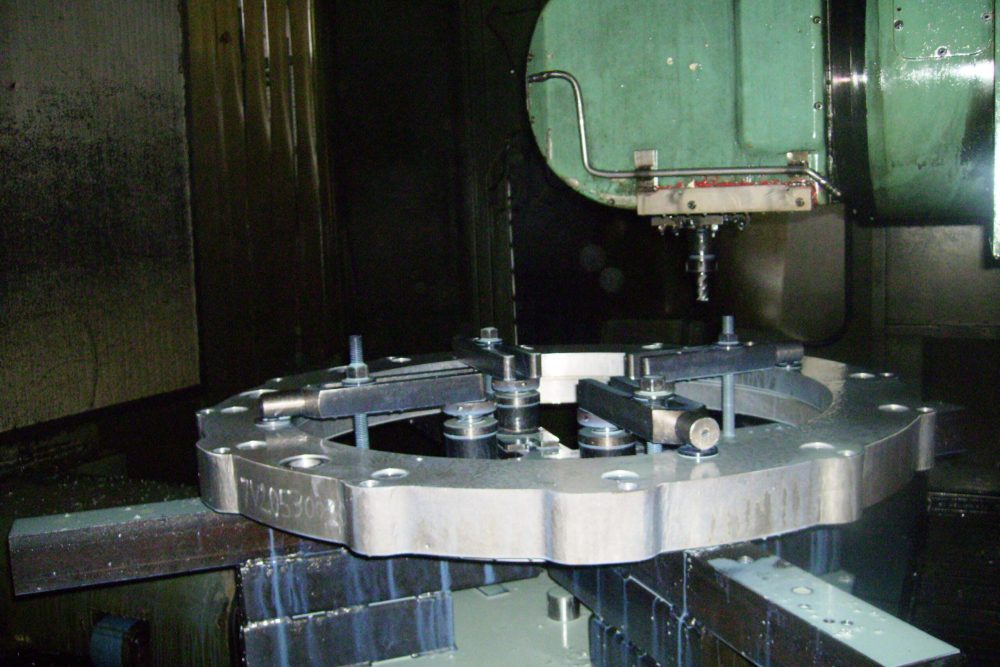

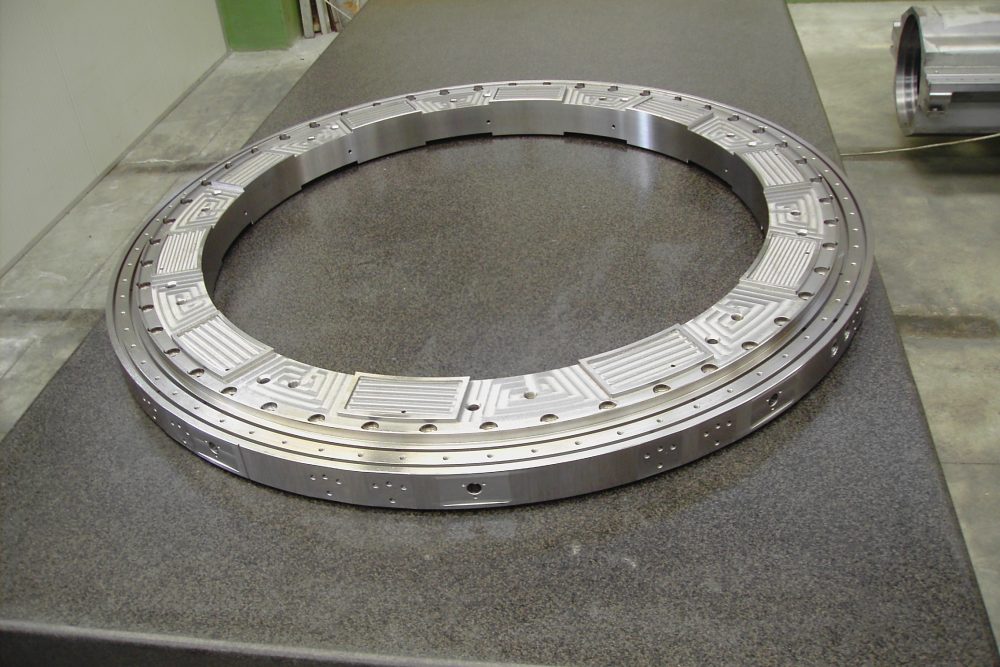

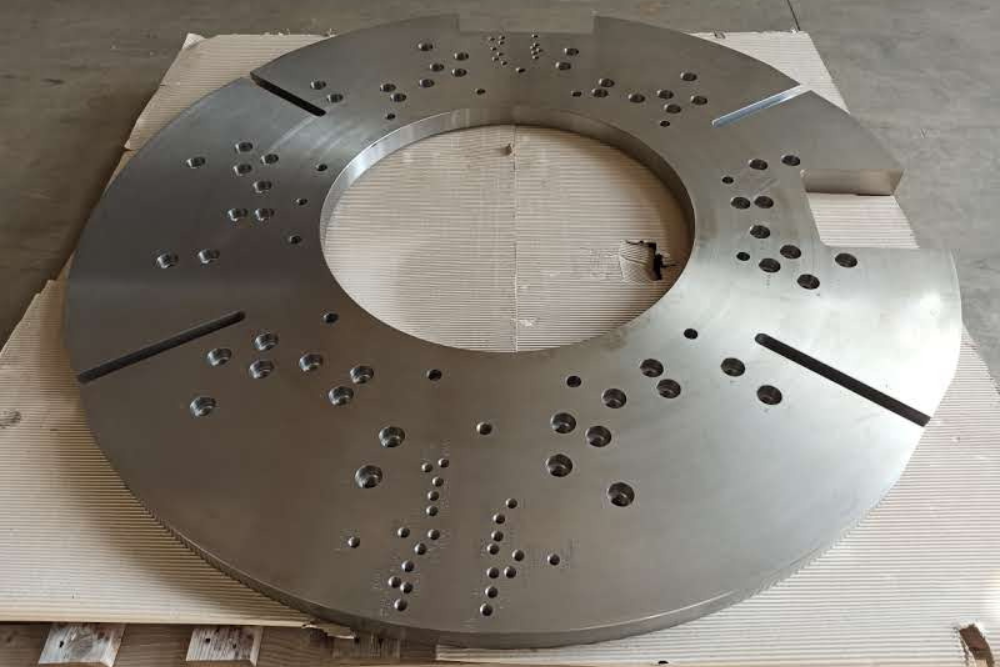

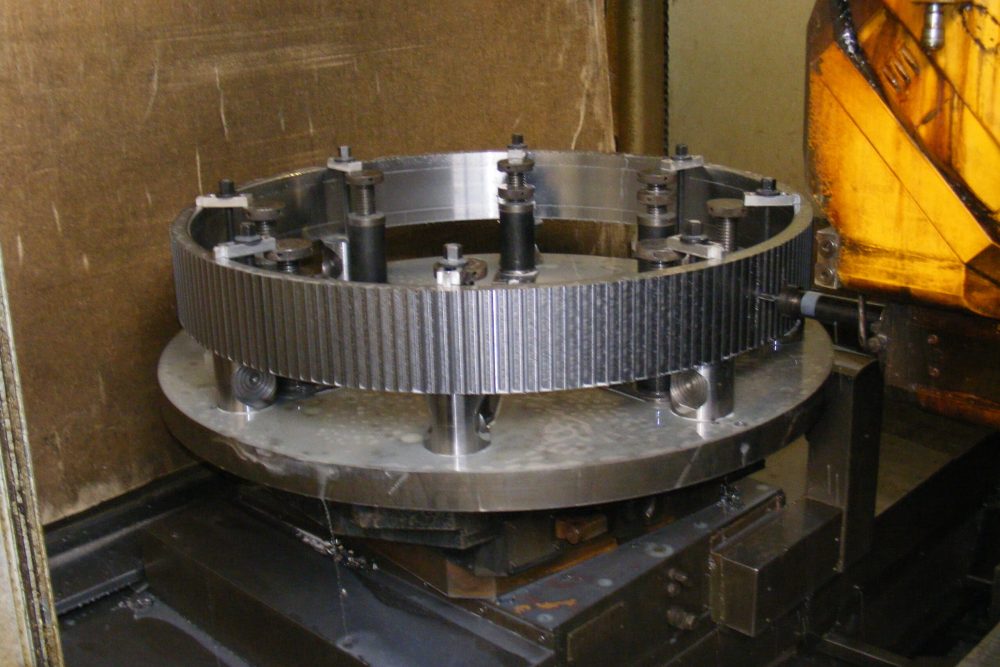

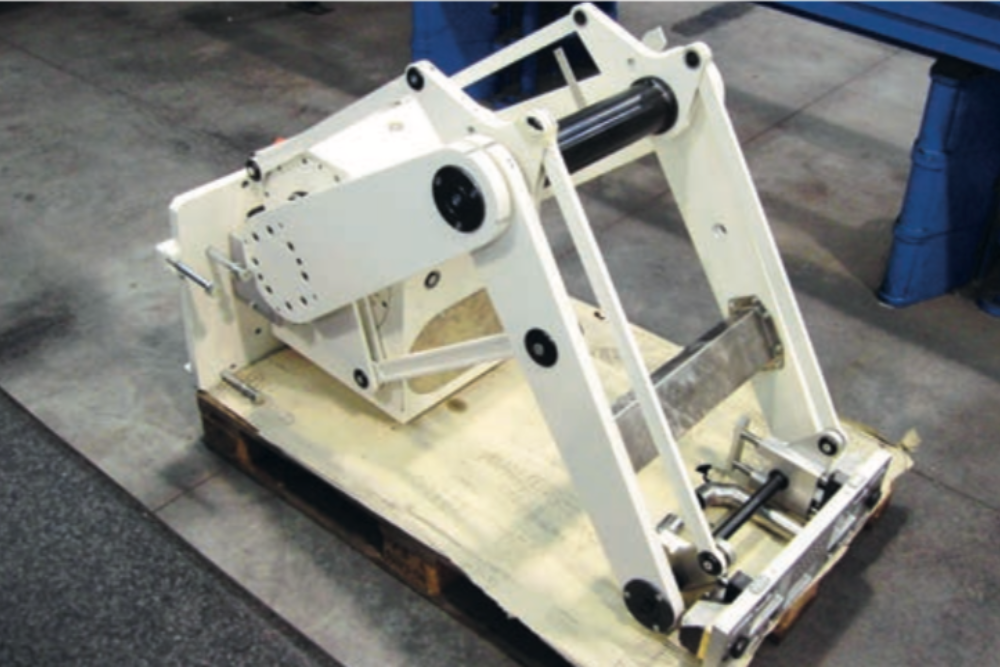

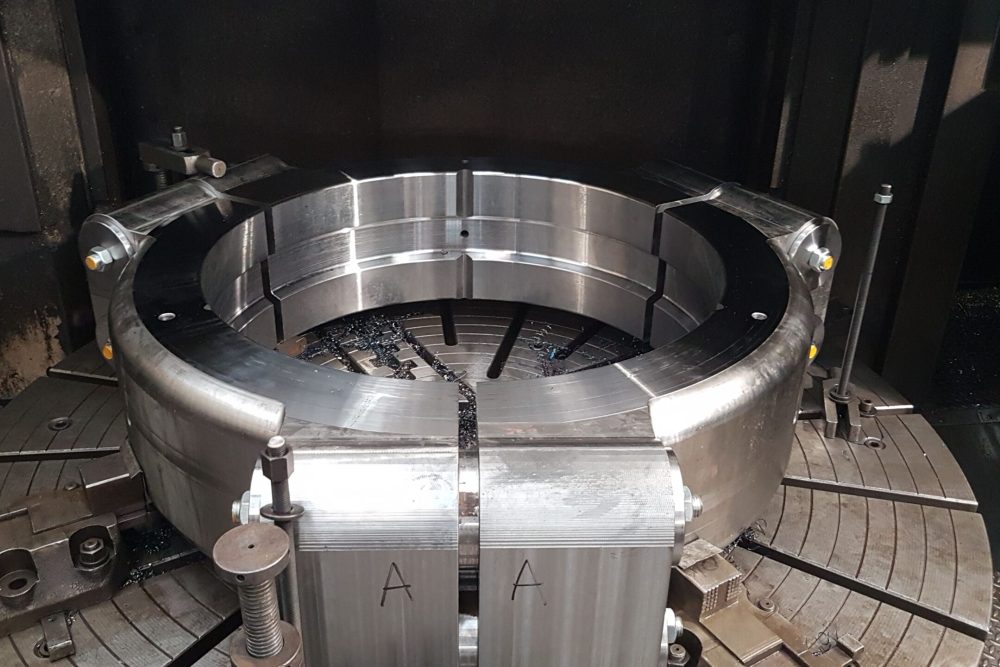

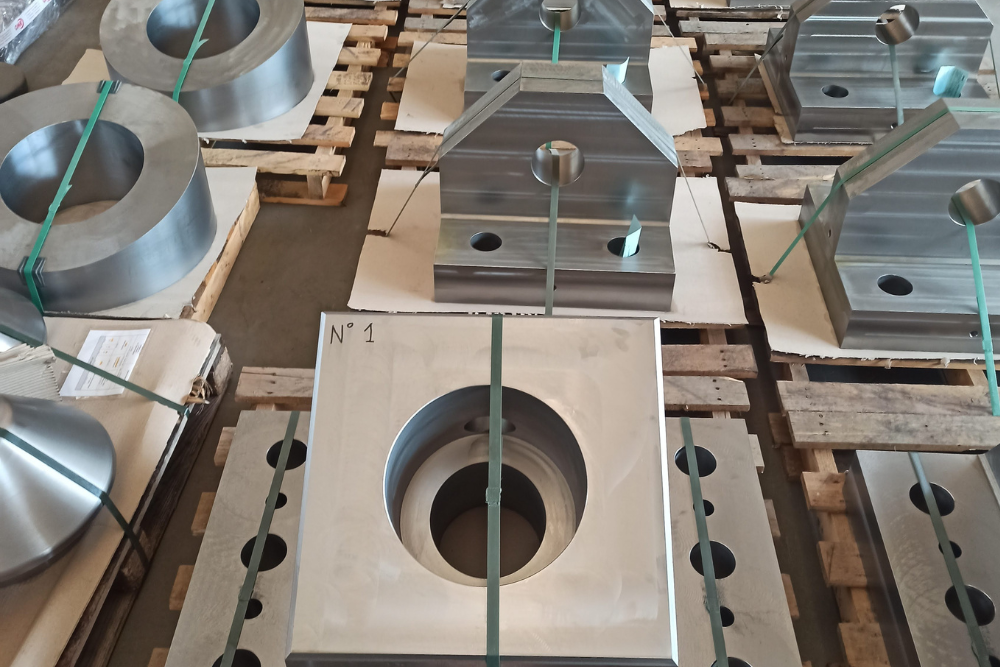

Title: Construction of turntables

Description:

All our tables can be interfaced with the CNCs of the machine tools on which they are mounted or they can work independently of the machine tool, managed by the CNC in an electrical cabinet with a hydraulic unit on a trolley.

According to the application for which they are intended and to the size and capacity, the tables can be built with 2 types of transmission and handling:

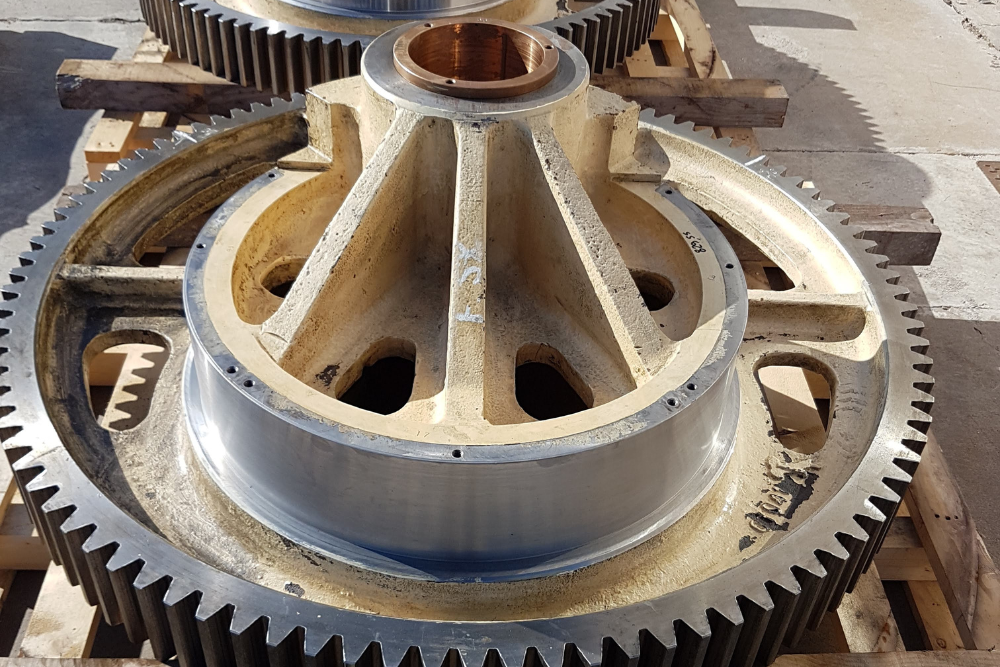

1) Mechanical transmission tables which, based on the size, have been designed with 2 different handling systems:

1A) Tables with horizontal and vertical axis with screw / crown mechanical transmission mainly used on tables with dimensions up to 1250x1250 and capacity up to 10 Ton built with axial bearing

radial

1B) Tables with vertical axis and mainly built in rotation on a LUBRICATED scraped track

FORCED on oil film semi-hydrostatic and hydrostatic with mechanical transmission by means of a toothed crown and double preloaded pinion gearbox.

This system is adopted for medium / large tables with capacities from 12 Ton to 70 Ton both rotating and roto-translating

2) Direct drive tables built with torque motors in collaboration with the best manufacturers of

engines worldwide

These types of tables are mainly built for turning and grinding.

OMR is able to build tables for turning, drilling and grinding centers, including palletized ones.

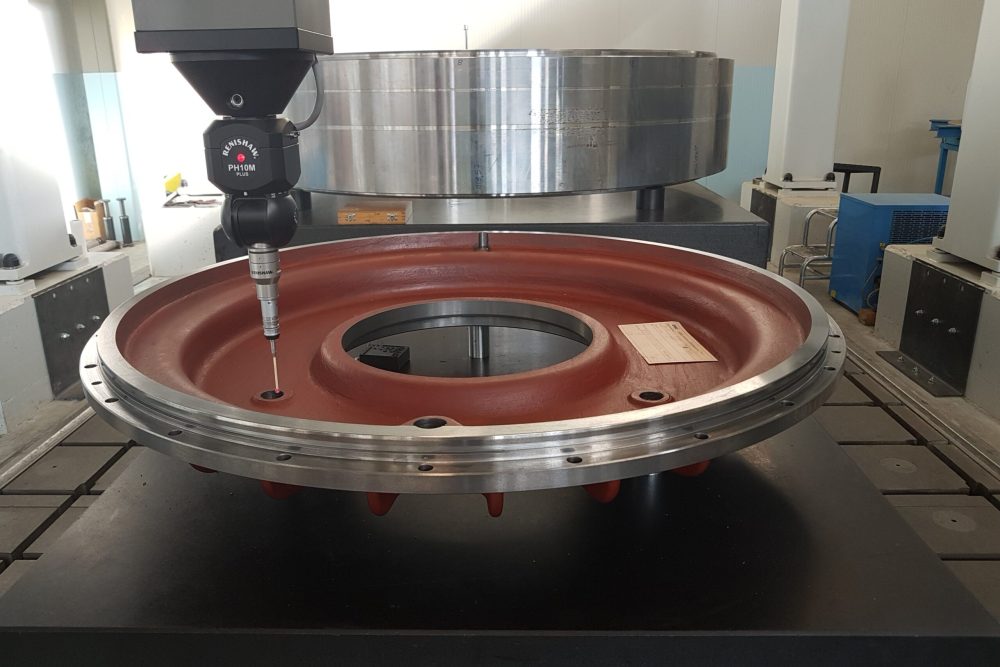

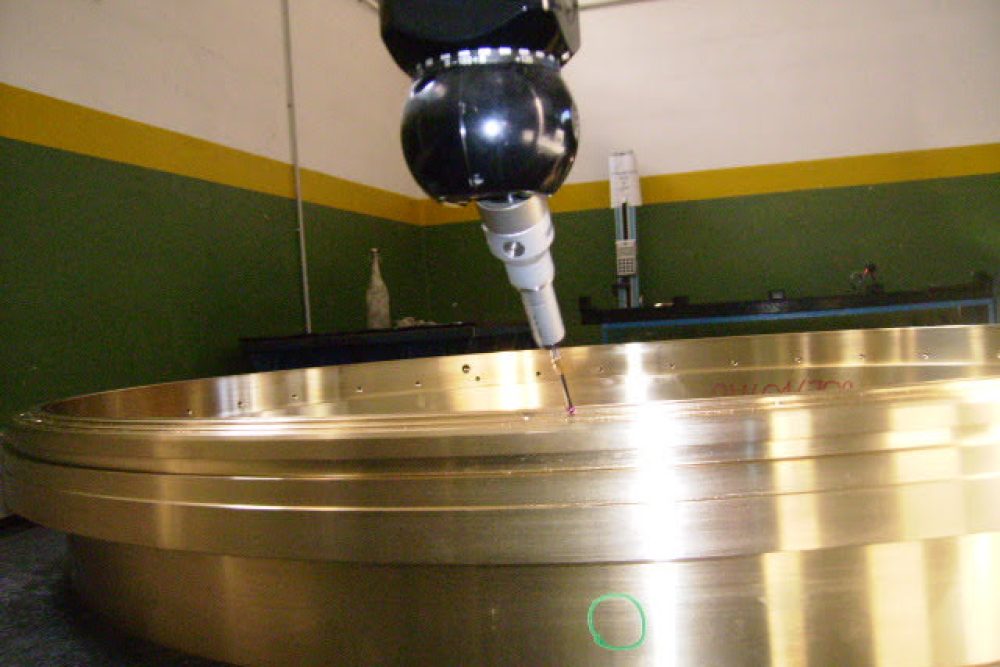

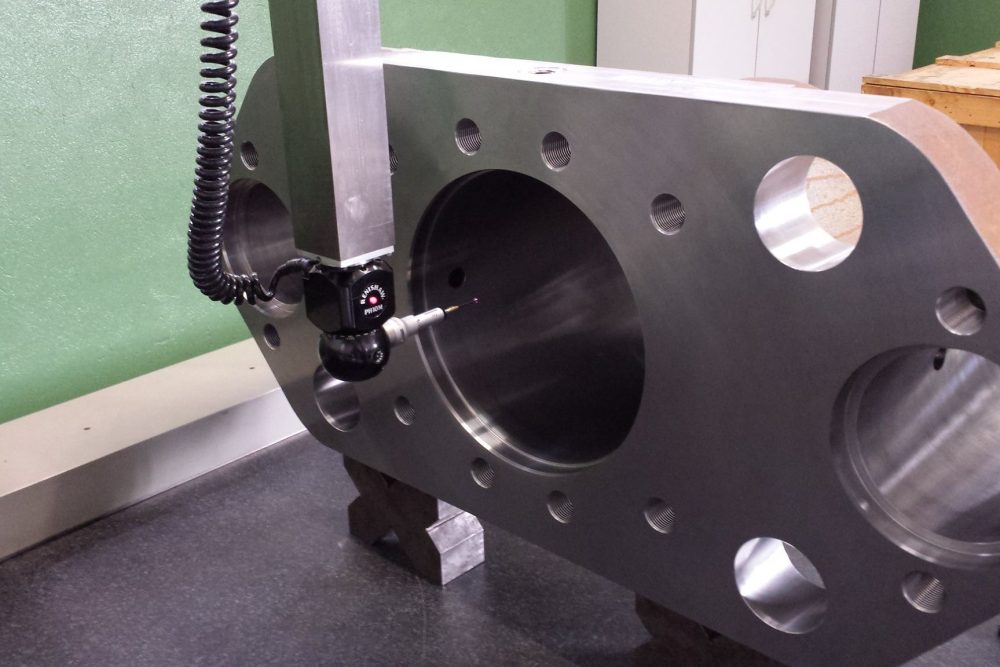

Before shipment, each table is geometrically tested and subjected to work simulations by means of a CNC test bench which issues a certificate showing the real precision and performance of the table.

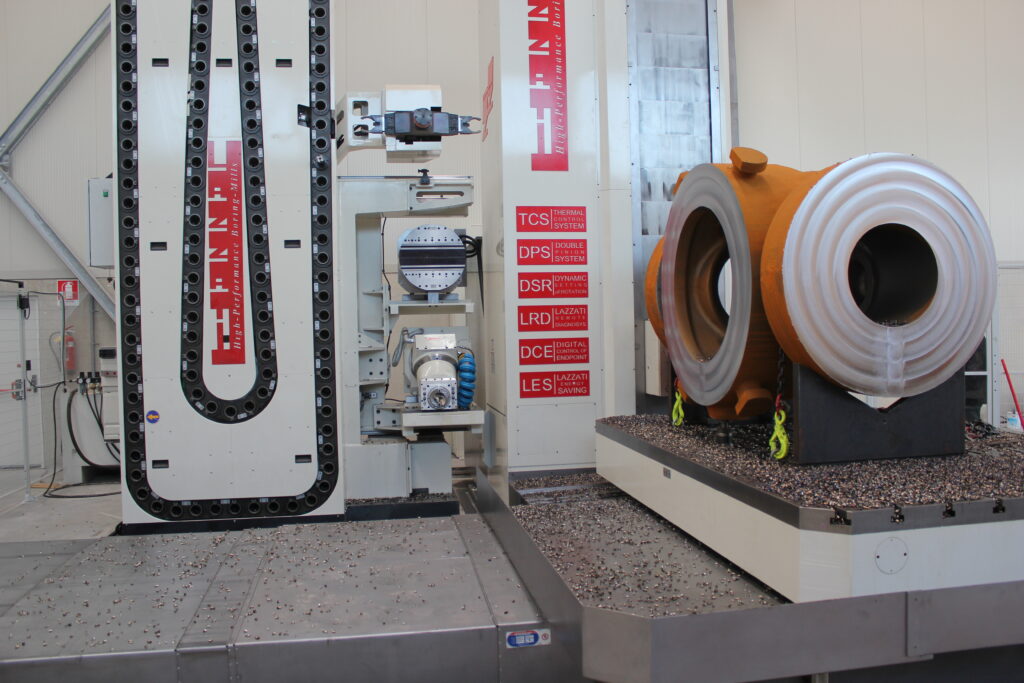

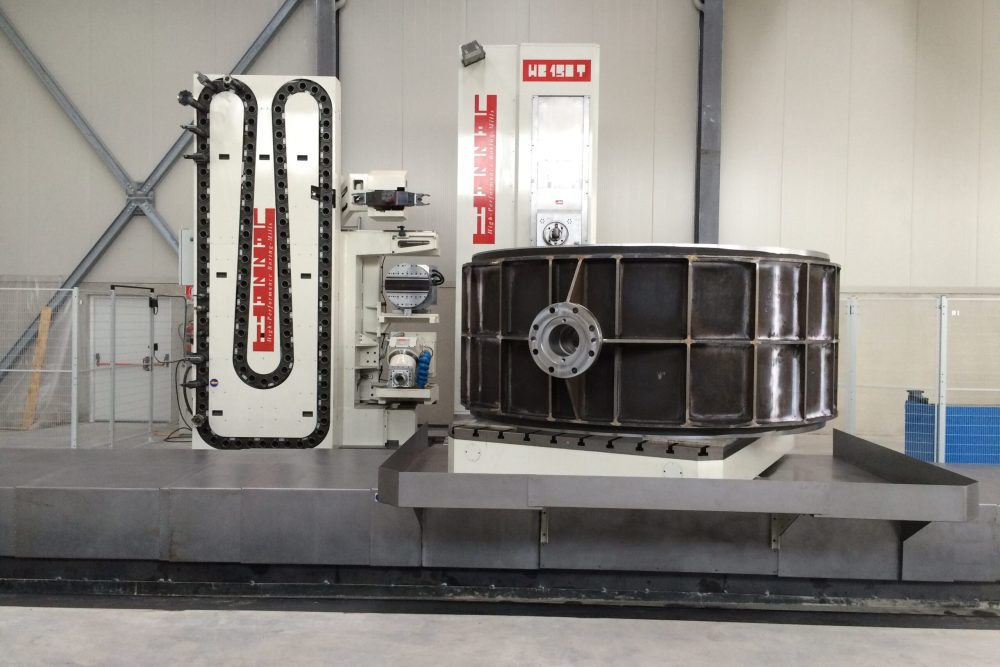

The continuous rotation rotary tables built by OMR are mainly used on machining centers, mobile column boring machines and special turning and drilling machines.

Title: Construction of turntables

Description:

All our tables can be interfaced with the CNCs of the machine tools on which they are mounted or they can work independently of the machine tool, managed by the CNC in an electrical cabinet with a hydraulic unit on a trolley.

According to the application for which they are intended and to the size and capacity, the tables can be built with 2 types of transmission and handling:

1) Mechanical transmission tables which, based on the size, have been designed with 2 different handling systems:

1A) Tables with horizontal and vertical axis with screw / crown mechanical transmission mainly used on tables with dimensions up to 1250x1250 and capacity up to 10 Ton built with axial bearing

radial

1B) Tables with vertical axis and mainly built in rotation on a LUBRICATED scraped track

FORCED on oil film semi-hydrostatic and hydrostatic with mechanical transmission by means of a toothed crown and double preloaded pinion gearbox.

This system is adopted for medium / large tables with capacities from 12 Ton to 70 Ton both rotating and roto-translating

2) Direct drive tables built with torque motors in collaboration with the best manufacturers of

engines worldwide

These types of tables are mainly built for turning and grinding.

OMR is able to build tables for turning, drilling and grinding centers, including palletized ones.

Before shipment, each table is geometrically tested and subjected to work simulations by means of a CNC test bench which issues a certificate showing the real precision and performance of the table.

The continuous rotation rotary tables built by OMR are mainly used on machining centers, mobile column boring machines and special turning and drilling machines.

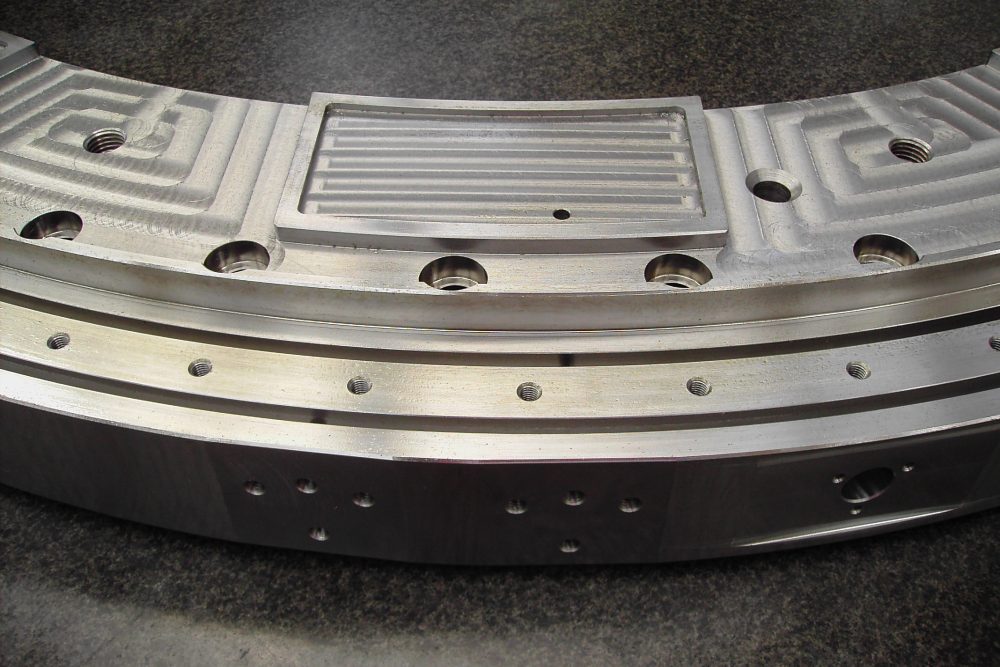

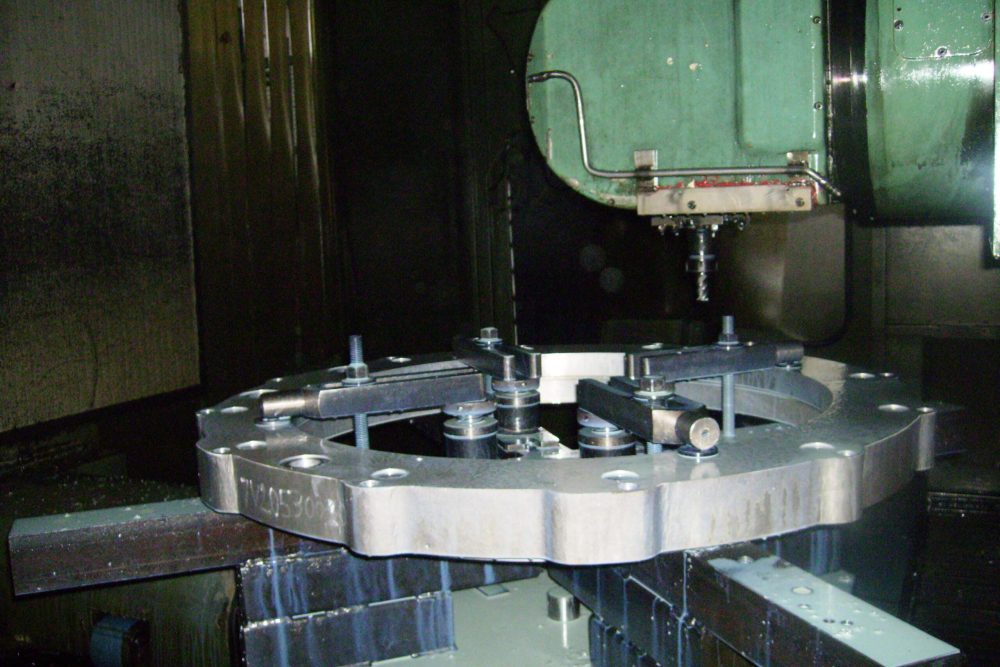

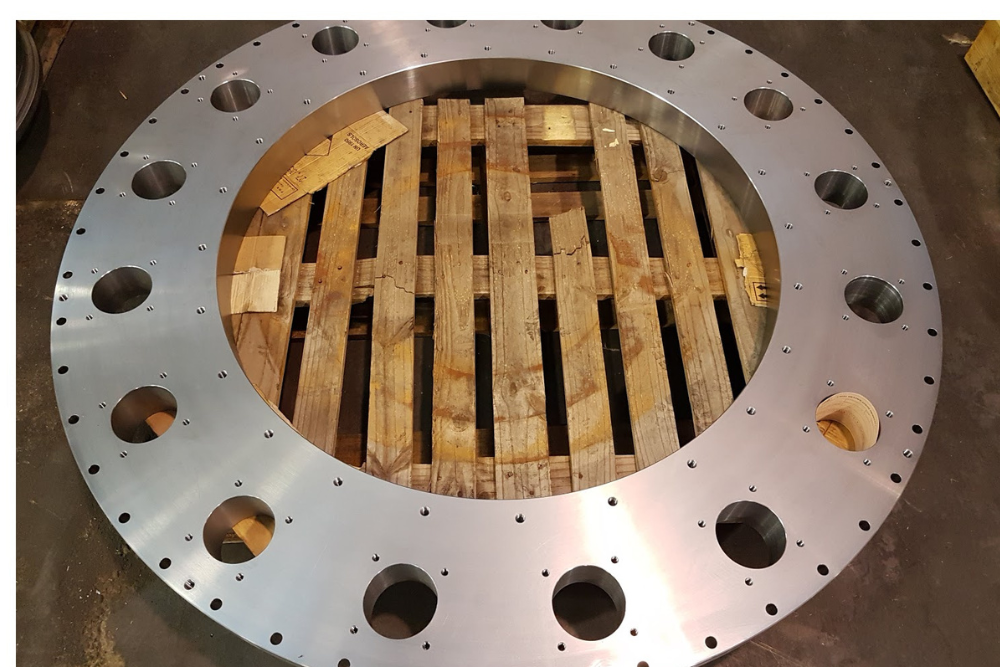

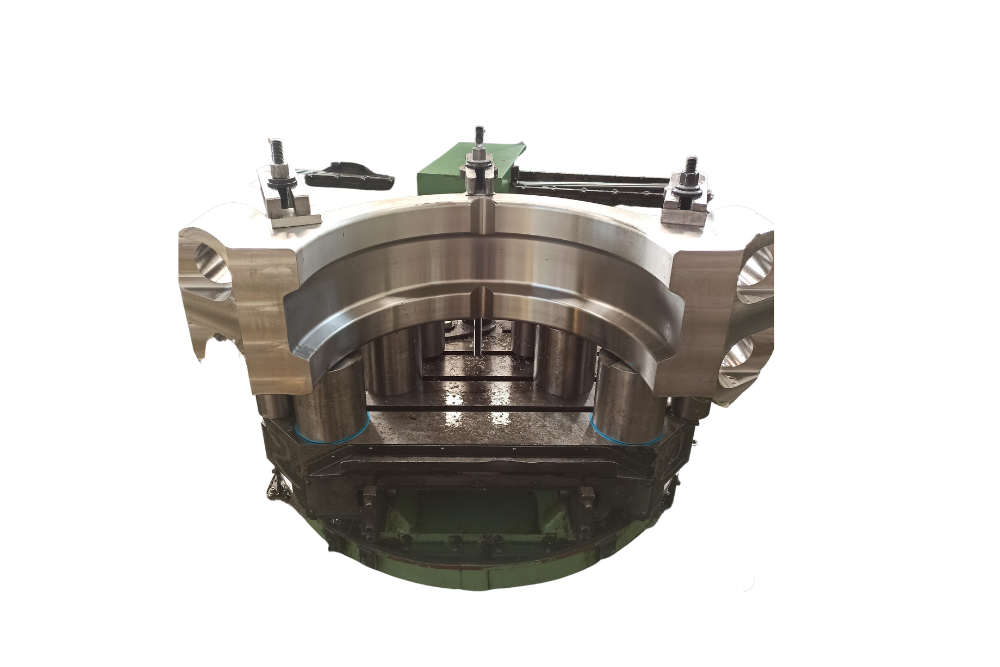

Title: Construction of turntables

Description:

All our tables can be interfaced with the CNCs of the machine tools on which they are mounted or they can work independently of the machine tool, managed by the CNC in an electrical cabinet with a hydraulic unit on a trolley.

According to the application for which they are intended and to the size and capacity, the tables can be built with 2 types of transmission and handling:

1) Mechanical transmission tables which, based on the size, have been designed with 2 different handling systems:

1A) Tables with horizontal and vertical axis with screw / crown mechanical transmission mainly used on tables with dimensions up to 1250x1250 and capacity up to 10 Ton built with axial bearing

radial

1B) Tables with vertical axis and mainly built in rotation on a LUBRICATED scraped track

FORCED on oil film semi-hydrostatic and hydrostatic with mechanical transmission by means of a toothed crown and double preloaded pinion gearbox.

This system is adopted for medium / large tables with capacities from 12 Ton to 70 Ton both rotating and roto-translating

2) Direct drive tables built with torque motors in collaboration with the best manufacturers of

engines worldwide

These types of tables are mainly built for turning and grinding.

OMR is able to build tables for turning, drilling and grinding centers, including palletized ones.

Before shipment, each table is geometrically tested and subjected to work simulations by means of a CNC test bench which issues a certificate showing the real precision and performance of the table.

The continuous rotation rotary tables built by OMR are mainly used on machining centers, mobile column boring machines and special turning and drilling machines.

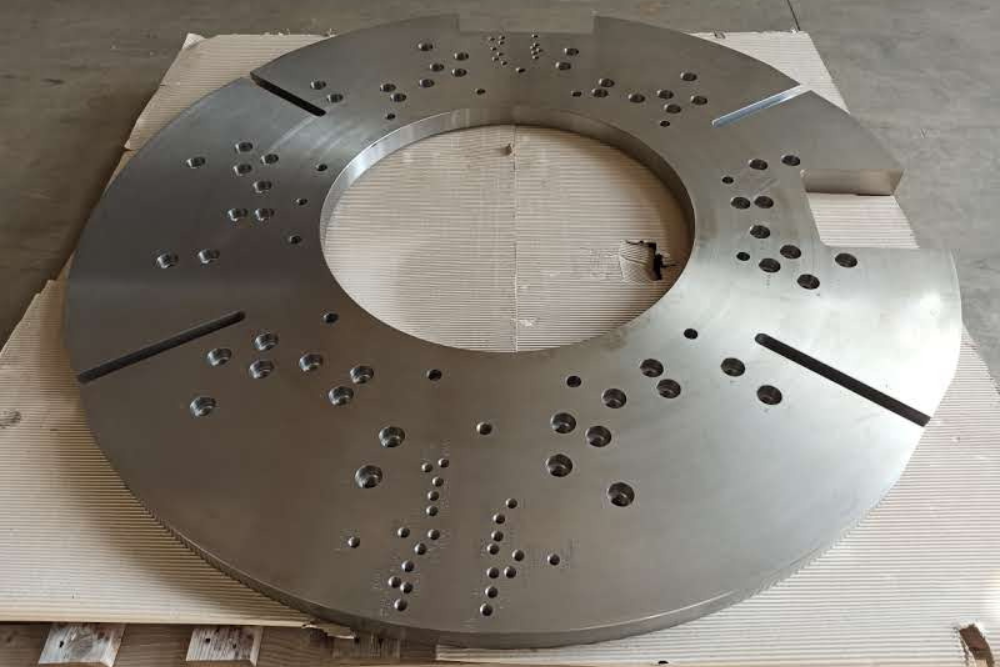

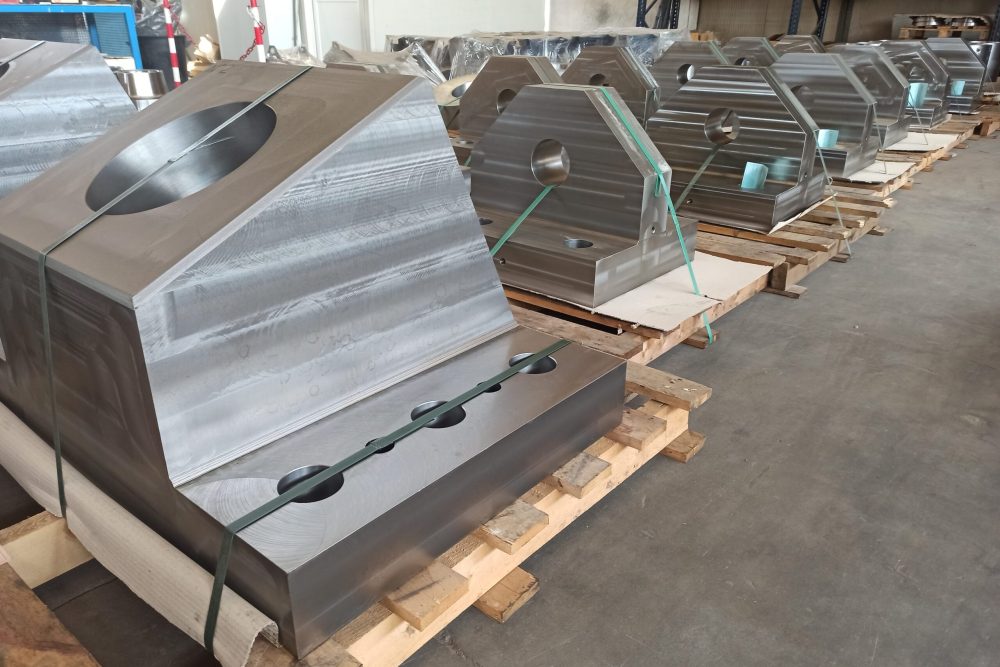

Title: Construction of turntables

Description:

All our tables can be interfaced with the CNCs of the machine tools on which they are mounted or they can work independently of the machine tool, managed by the CNC in an electrical cabinet with a hydraulic unit on a trolley.

According to the application for which they are intended and to the size and capacity, the tables can be built with 2 types of transmission and handling:

1) Mechanical transmission tables which, based on the size, have been designed with 2 different handling systems:

1A) Tables with horizontal and vertical axis with screw / crown mechanical transmission mainly used on tables with dimensions up to 1250x1250 and capacity up to 10 Ton built with axial bearing

radial

1B) Tables with vertical axis and mainly built in rotation on a LUBRICATED scraped track

FORCED on oil film semi-hydrostatic and hydrostatic with mechanical transmission by means of a toothed crown and double preloaded pinion gearbox.

This system is adopted for medium / large tables with capacities from 12 Ton to 70 Ton both rotating and roto-translating

2) Direct drive tables built with torque motors in collaboration with the best manufacturers of

engines worldwide

These types of tables are mainly built for turning and grinding.

OMR is able to build tables for turning, drilling and grinding centers, including palletized ones.

Before shipment, each table is geometrically tested and subjected to work simulations by means of a CNC test bench which issues a certificate showing the real precision and performance of the table.

The continuous rotation rotary tables built by OMR are mainly used on machining centers, mobile column boring machines and special turning and drilling machines.

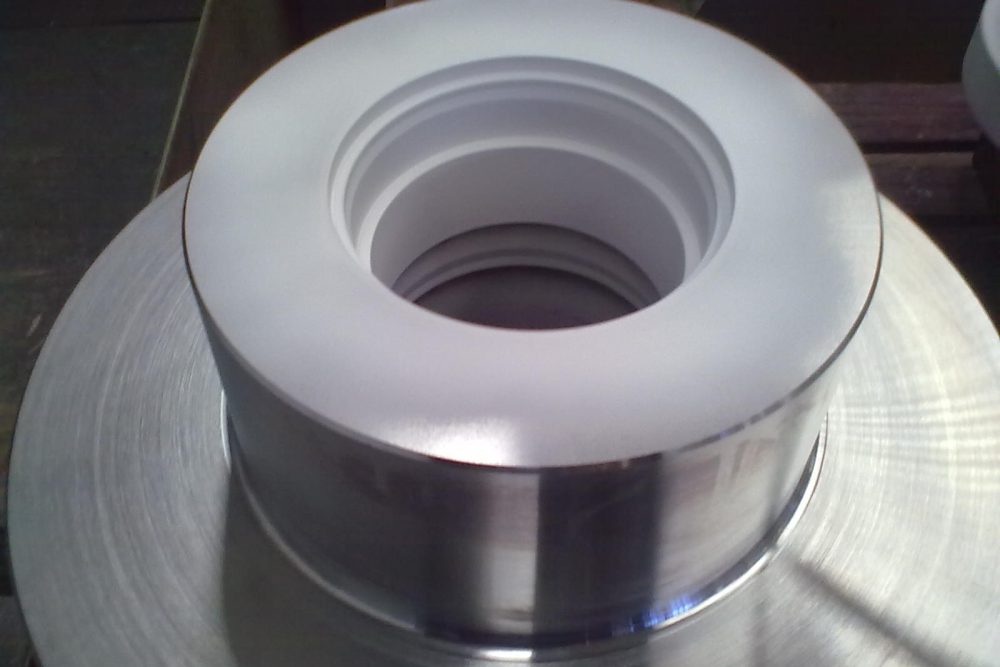

Title: Hydraulic clamping bushes

Description:

Another product belonging to OMR's own productions are the hydraulic clamping bushes.

These bushings, normally fringed, are built according to the customer's requests and not used

only on machine tools, but also in the most varied mechanical sectors where locking of

high safety in small spaces.

The OMR division specialized in assembly has qualified personnel, with years of experience in theassembly of rotary tables - even large ones - parts of machine tools, conveyor lines, machinery and robots.

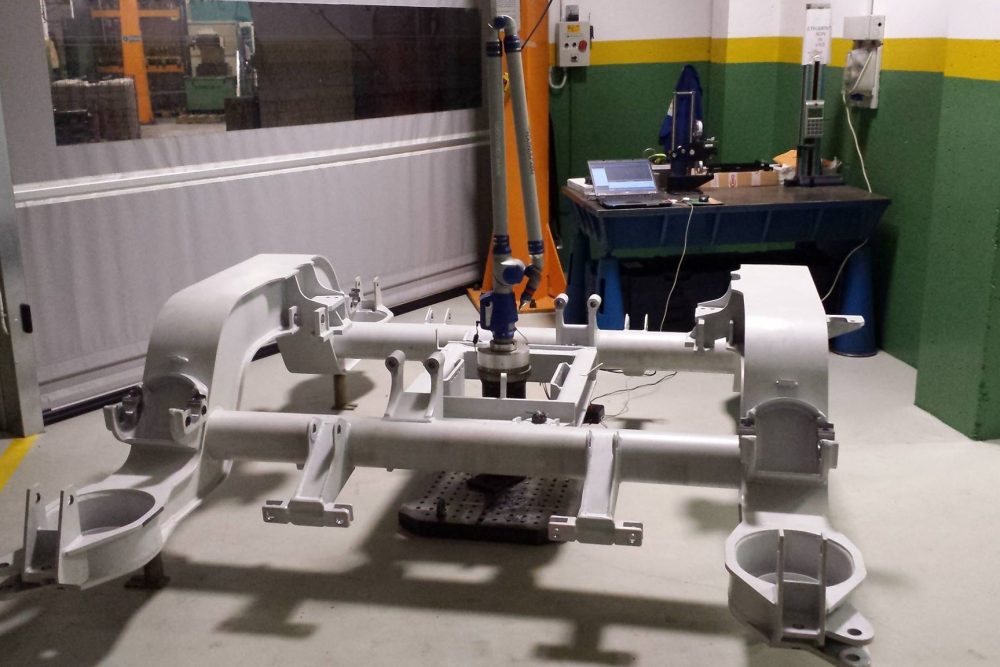

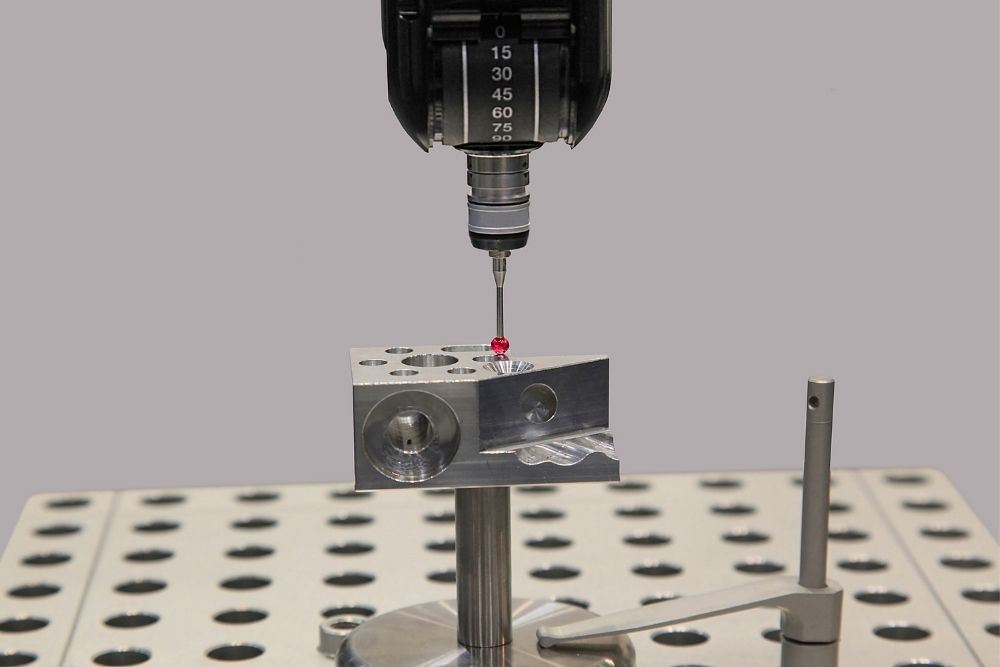

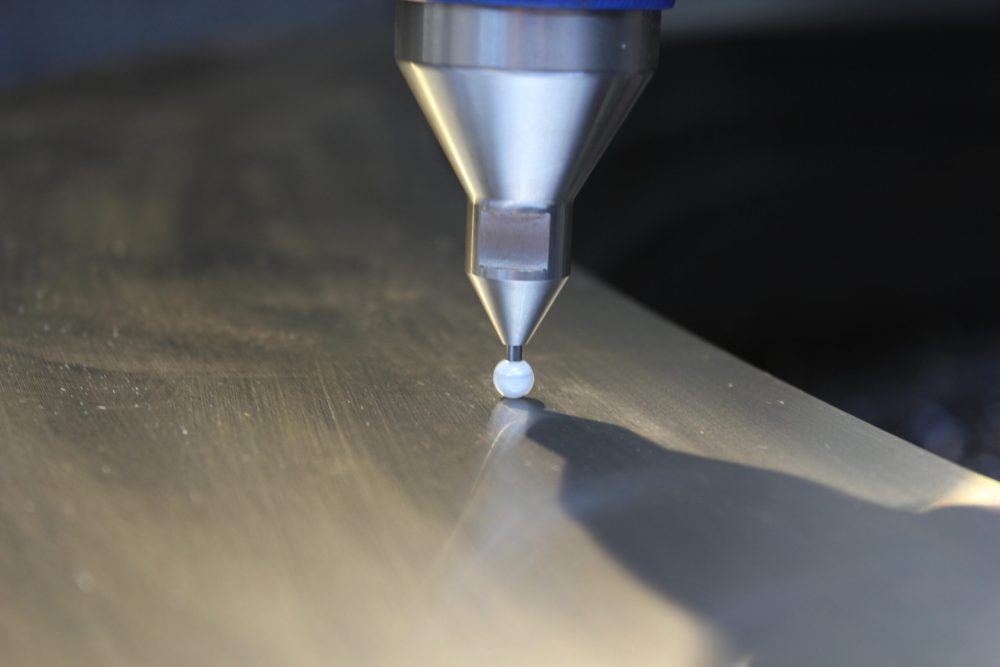

Attentive and coordinated managers manage the testing department with three-dimensional CNC machine of large dimensions 6000x3000x2500 mm, portable robot with articulated arm “FARO”, electronic bubble, collimator and other sophisticated control instruments kept constantly efficient and regularly calibrated.

Officina Meccanica Ravera boasts a good wealth of experience and skills also in threading department, thanks to the possession of highly trained human resources with years of experience in this type of processing behind them.

A qualified, attentive and coordinated technical team manages the drilling department.

A large fleet of machines and the experience of the personnel in charge of machining on machine tools are essential to carry out machining of marking quality.

OMR is not equipped internally to carry out grinding operations but collaborates with highly certified suppliers on an ongoing basis

The company also carries out processing of sandblasting with great precision and attention to detail.

Our welding island is composed of a Comau Smart NS 12-1.185 industrial robot with 6 controlled axes with a maximum load on the wrist of 12 Kg. The robot is mounted on a flag column, having a sliding carriage with interpolated brushless motor, with useful travel 15000 mm.

OMR also boasts a good experience in deburring, thanks to the formation of a team of technicians ready to respond carefully to customer requests.

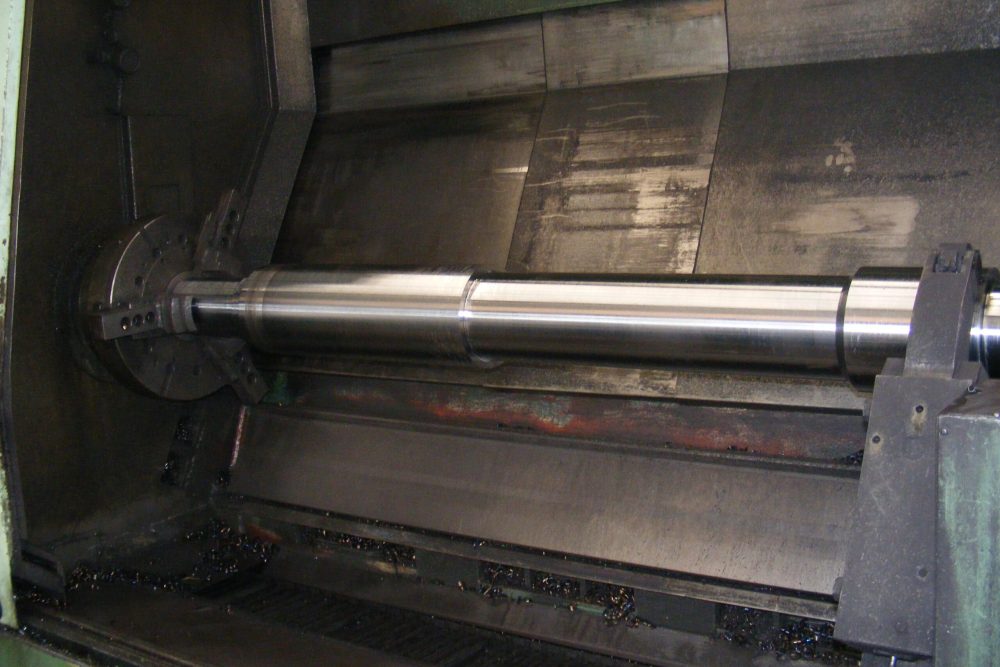

the department turning light machining is dedicated to mass production for various production sectors. According to the quantities and types of pieces produced, some machines can work partially unattended.

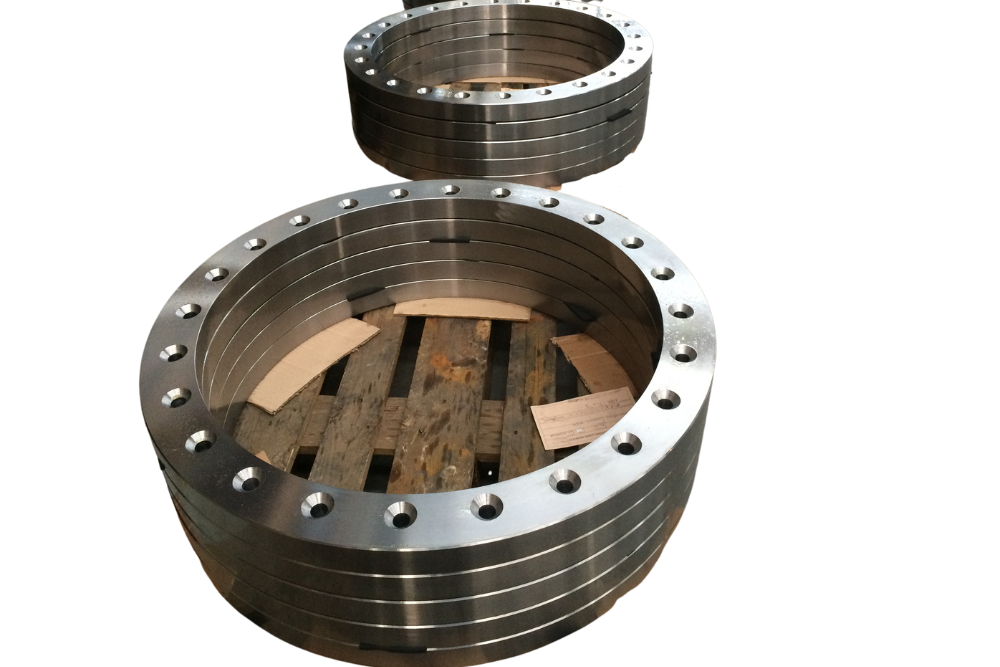

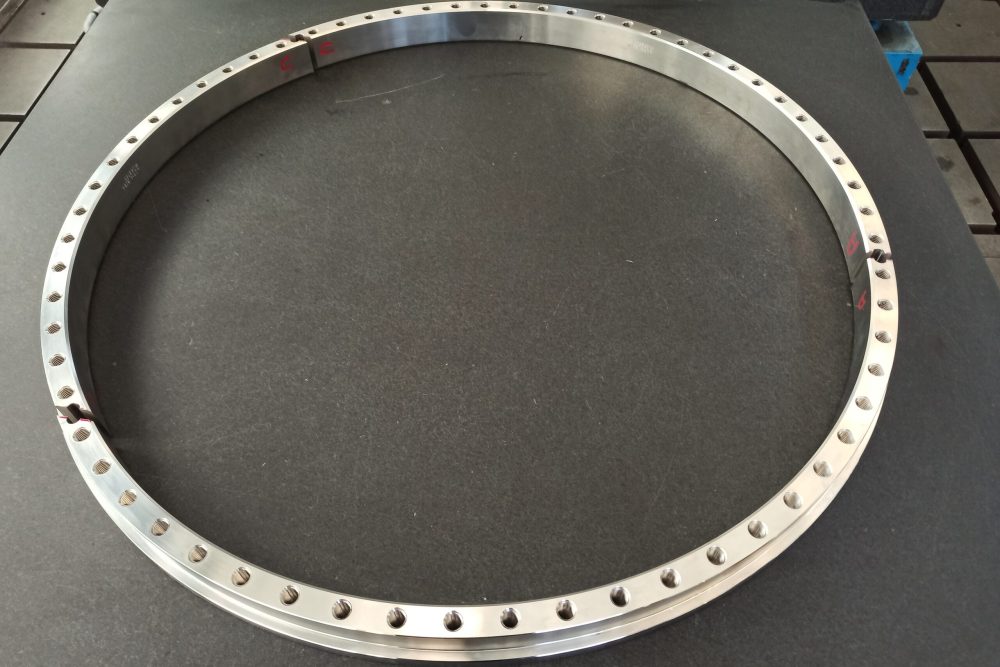

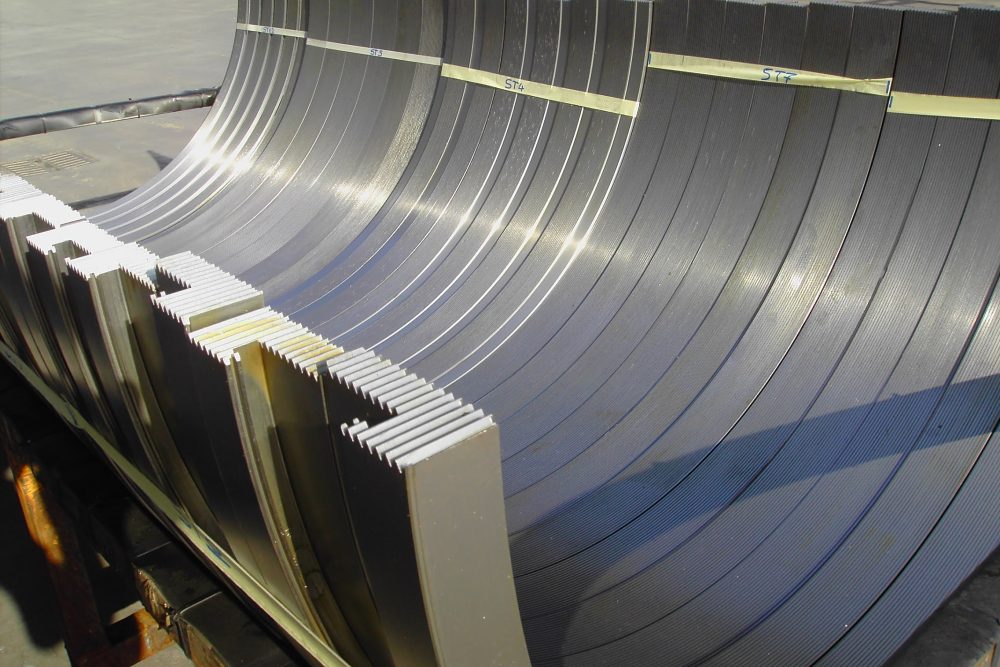

The section turning medium-heavy machining is particularly equipped with over 20 vertical lathes for machining in the industrial valve sector, in the wind sector for bearing rings up to Ø3200 mm and in the steel industry

Today OMR is an established company in precision mechanics, able to follow the entire production process, starting from the purchase of the raw material (in bar or casting, forged, oxy-cutting or custom-made carpentry) up to the final painting and mechanical assembly. to drawing.

We also build - on our own design - medium / large-sized continuous rotary tables for machine tools, not excluding the possibility of building continuous rotary tables based on the customer's project.

The family management associated with the collaboration of 90 employees and a good number of qualified suppliers, make the company a professionally serious, solid and prepared to accommodate the needs of the market.

The company is located on a total area of 23.000 m² (divided into two factories a few kilometers away from each other), its work areas are structured according to all safety regulations.

Both production units are equipped with overhead cranes with capacities from 6,3 tons to 30 tons, distributed according to the loading needs of the various machines.

The storage of raw parts is done on a large yard easily accessible by trucks. OMR manufactures parts according to the customer's design (in C / L or complete supply), which are used in various production sectors such as energy (Oil & Gas, wind, hydroelectric, motors), petrochemical, mechanical, railway, earthmoving, automotive, robotics , packaging and food.

Furthermore OMR is able to supply stabilized carpentry, primed painted, machined with machine tools up to a maximum weight of 30 Tons and workable overall dimensions of 10.000x2500x2000. For the construction of heavy carpentry OMR makes use of 2/3 suppliers in the area, highly qualified, with a large stock of certified sheets and licensed welders.

In the plant sector for food and confectionery industries and in the Automotive sector, OMR builds parts and assembles groups, sub-groups and parts of production lines or complete lines based on the customer's design.

OMR builds parts and assembles groups, subgroups and parts of production lines or complete lines according to the customer's design, in the automotive systems sector.

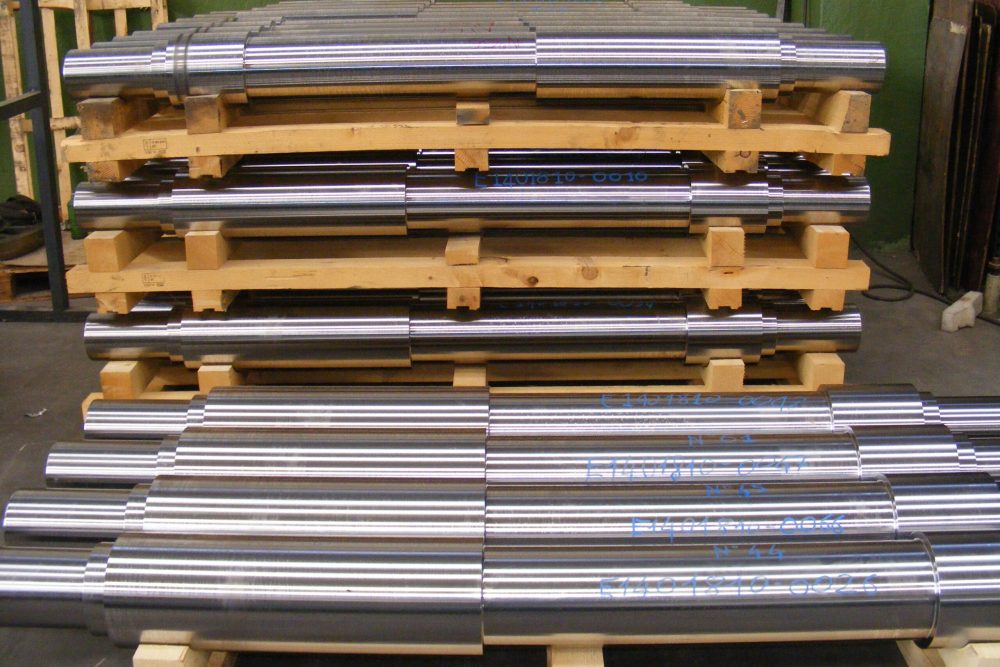

For the wind sector OMR is equipped with vertical lathes and machining centers to work bearing rings from Ø800 / 1000 mm to Ø3300 mm. There are numerous in-house machines equipped for this type of detail, therefore the production capacity for this product can reach 500/600 hours / month.

For the railway sector, OMR performs the machining of carriages, axles and wheels of trains on machine tools.

For the processing of train wheels to be shipped by sea, OMR has a Tectyl protective application system with a dedicated fume extraction system. In this sector OMR also builds mechanical parts dedicated to ordinary and extraordinary maintenance for railways.

In the machine tools sector, machinery for steel processing and deformation, plants for steel mills, OMR has experience in the processing of components for rolling mills, components for calendering machines and parts for various transmission components. OMR also builds on its own design continuously rotating tables to be applied on boring machines and machining centers as an accessory. In collaboration with the machine tool builders OMR also builds table groups

special designed for dedicated applications.

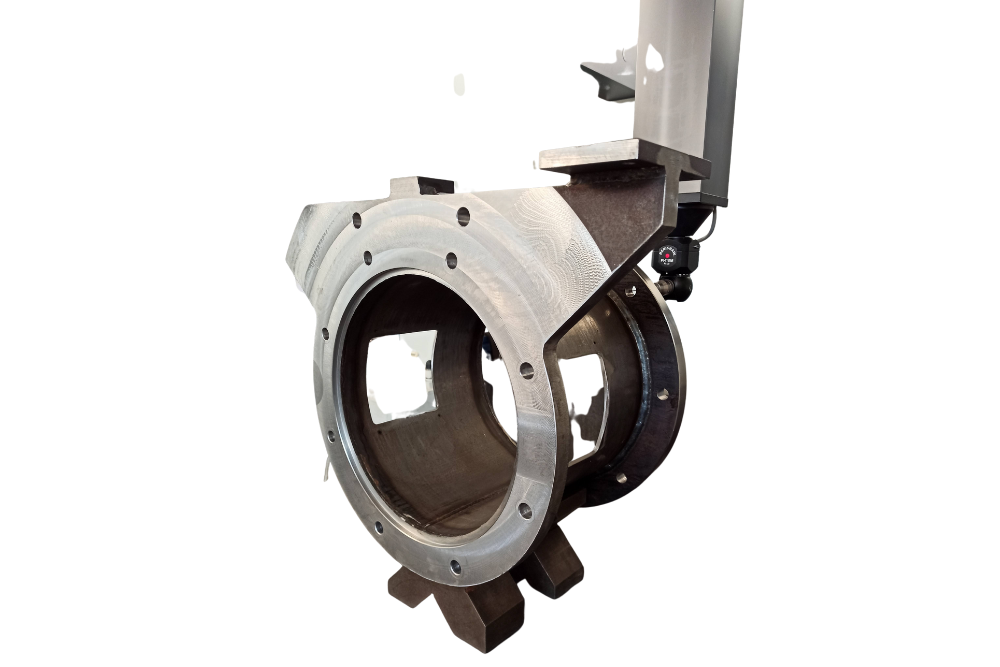

In the oil sector (industrial butterfly and ball valves), OMR processes valve components from 8 "to 100" max voltage 3300mm. OMR boasts over 25 years of experience in this sector. In addition to mechanical processing, OMR is equipped with robots for carrying over in Stellite gr21 on a conical seat of valve and butterfly bodies. As far as ball valves are concerned, OMR believes it has excellent experience in the processing of INCONEL 625.

We carry out processing of

pistons, engine casing, shields, flywheels and other components for compressors for heavy vehicle refueling stations.

OMR is structured to manage the complete supply of equipment according to the customer's project.

OMR has experience in the manufacturing of lids

for quarry truck drive shafts and other components in the earthmoving sector.

OMR processes casings, caps, three-phase electric motors and water-cooled motors.

We carry out machining of components according to the customer's design of exchangers, equipment and components

by N2 hydrogen production / distribution sector

We are equipped to carry out machining / supply of flywheels, gears and special joints

We carry out machining of components for Francis, Pelton and Kaplan turbines, components of

ball and butterfly valves.

We carry out processing of welded and medium / large-sized carpentry work on account or in supply

collaborating with selected carpentry suppliers.

We have experience in machining rings, flanges and other components in the medical sector.

We carry out processing of

bushings for transmission shafts in the naval sector, valves and various details for the naval sector e

offshore platforms.

For the robotics sector we work medium / large parts

bulk batch sizes.

We have gained good

experience in manufacturing large size detachable collars.

We are equipped with state-of-the-art measuring instruments to constantly monitor production on the machine by carrying out on-the-job training. Our testing department is equipped with TAR AL up to 4000mm for calibrating bars and measuring instruments, Faro Arm and CMM 3D 6000 × 3000 h 2000mm machine installed in an air-conditioned room.

We return and mill parts in series starting from forged for various applications up to

Ø3000mm and 20ton.

We are equipped with over 20 vertical lathes equipped with magnetic table operating on several shifts and WE ARE SEARCHING for parts in medium / large series

With a view to diversification and with the aim of always acquiring new skills OMR is interested and works every day to enter new sectors of mechanics such as:

In the last 12 months, a new multinational customer has been acquired in the sector of machinery and plants for paper and cardboard processing and a local customer who is a manufacturer of glass processing machinery.

I production departments of OMR are conceived on the basis of the size and quantity of the batches to be produced.

The quality assurance, as well as from an efficient fleet of machines constantly subjected to preventive maintenance, is given by qualified personnel.

OMR has obtained quality certification in the field of precision mechanical machining based on customer drawings, according to the ISO 9001: 2015 standard.