| Top machining |

Threading, Drilling, Marking, Tapping, Design, Prototyping, Rapid Prototyping

|

|---|---|

| Other processes |

Sandblasting

|

| Operating sectors |

Furniture, Automotive, Hobby, Plant Engineering, Medical, Packaging

|

| Work area | 1000 m² |

| Employees | 3 |

| Metals/Materials |

Plastic materials

|

La Paccalini Srl, was born in 1961 by Paccalini Rosolino and Vergani Anna, mainly produces accessories for leather goods, subsequently with the arrival of their son Angelo in the work team in 1980, there is a first turning point.

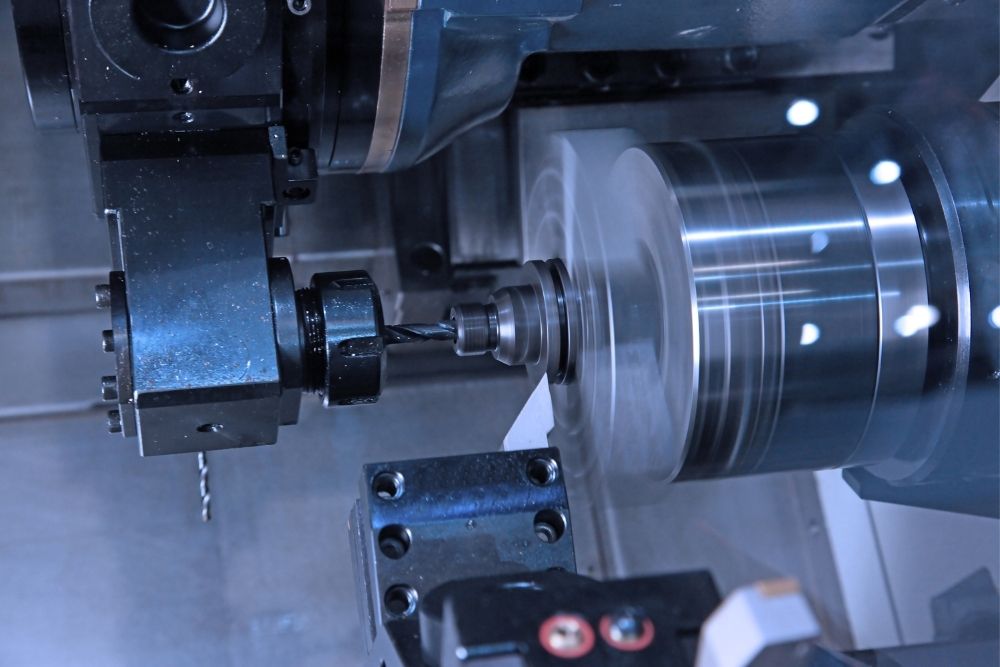

Angelo introduces new and increasingly specialized machinery, among which CNC machining centres, and transfer, up to producing small metal parts precision for the automotive sector.

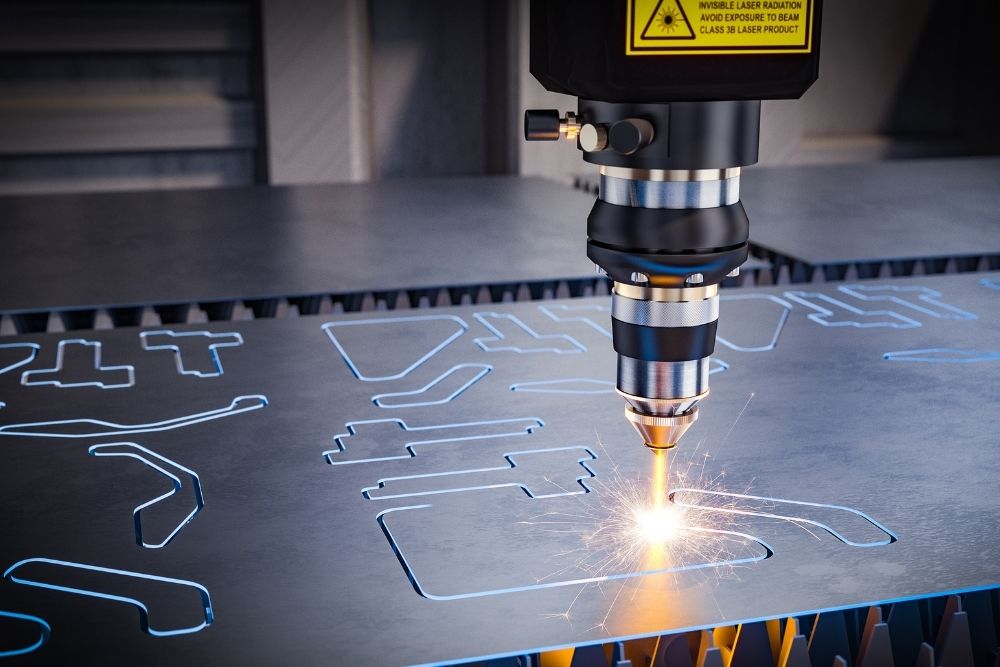

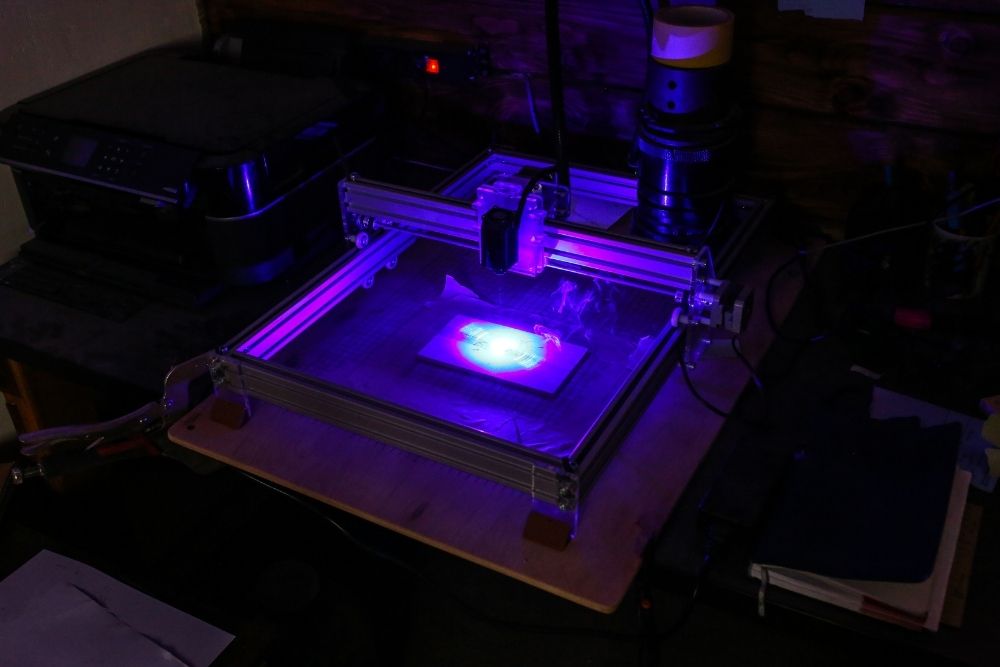

In 2009, Angelo decided to devote himself also to the working of Plexiglas, with laser cutting machines of various types, bending machines, gluing stations and with the latest arrival, the 5-axis machining center, which allows 3D machining.

Possibility of creating customized shapes thanks to the use of a dedicated professional folder, without affecting the nature of the material

Possibility of creating prototypes on customer request.

Possibility of using rapid prototyping for the physical realization of prototypes, in a relatively short time.

Possibility to carry out sandblasting operations with great precision and attention to detail.

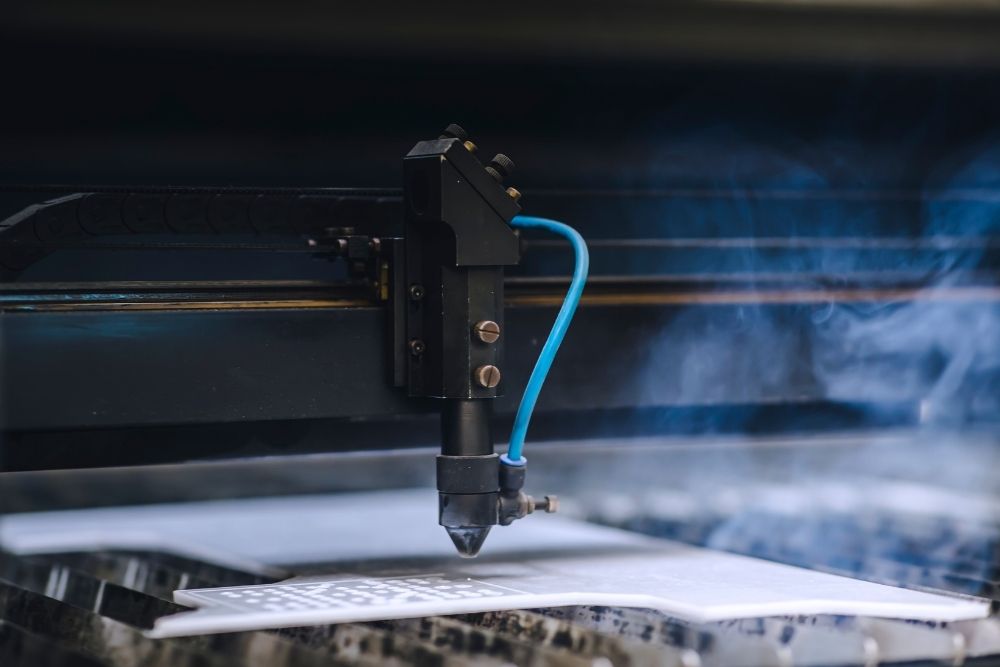

It takes place thanks to the use of a laser beam capable of cutting Plexiglass sheets of various thicknesses, ensuring perfect cuts without smudging.

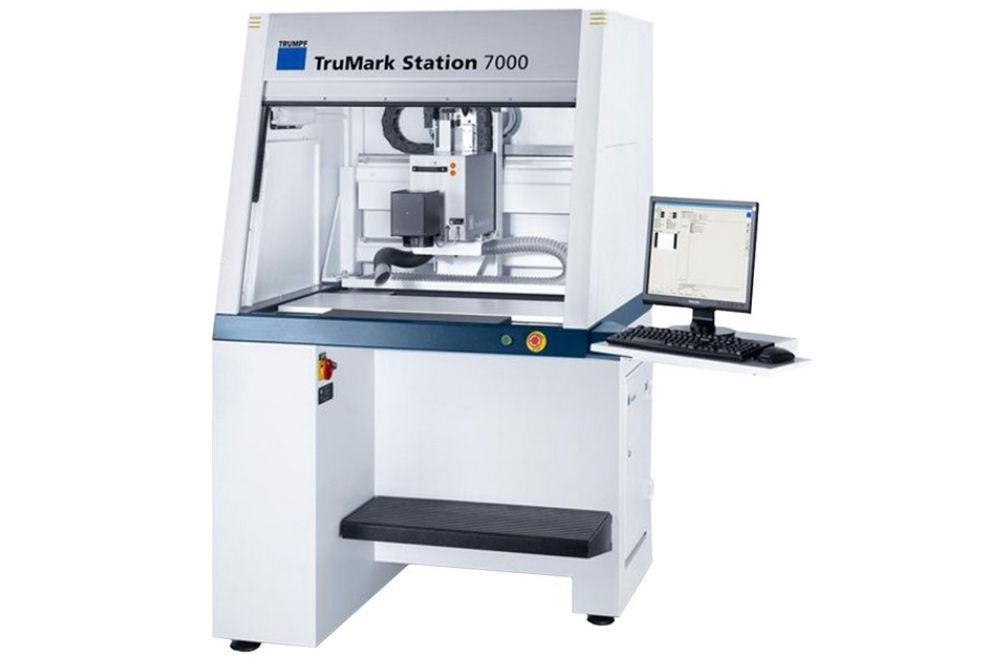

Title: Trumpf Trumark Station 7000

Features: Solid state laser source Nd: YAG

Title: Mimaki UJF-6042MkII

Features: Maximum print area 30x42cm.

Printing on even non-planar materials (height differences up to 4,5mm).

Direct printing on objects up to 153mm thick

Transparent ink for glossy, matte finishes and high-impact relief effects.

Simultaneous color and white printing.

High opacity white ink for transparent or dark tinted substrates.

Title: Six Laser Mercury 609 laser cutting and engraving machine

Features: Laser cutting machine with advanced and innovative technology, wide flexibility of use, high performance and safety, double plane for loading and unloading, XY axis movement with high performance motors, position control via optical scales.

Title: HP Jet Fusion 3 5200D Printer

Features:

- Nylon PA12 material

- Dimensional accuracy, + or - 0.20 mm up to 100 mm, over 0.20% of the nominal size

- Max printable piece volume: 380 × 284 × 380 mm

- Layer thickness: 0,08mm

- Sturdiness, reworkable, paintable, low porosity, pressure hold

- Possibility of making complex manifolds for air

For print files we can use formats

Title: HP Jet Fusion 5200 series

Features: The HP Jet Fusion 3 5200D Printer is the most advanced 3D plastic printing solution for mass production.

The HP Jet Fusion 3 5200D Printer has a production volume of 380 x 284 x 380mm and a new single pass configuration.

Title: Uniteam CNC Leader - Machining Center

Features: Simple and versatile machine with high productivity with reduced cooling time of the pieces.

Possibility to create fold angles up to 60 degrees and to make folds on several pieces at the same time or multiple folds on a single piece.

Title: Diamond grinder - Codema TI

Features:

Useful working length 3000 mm

Maximum working thickness 140 mm

HP high speed electrospindle. 1,5

Is simplicity an innovative and unique application in the sector? adjustment of the head inclination from -5 ° to + 60 °.

Title: Tgluing table

Features: Measures 100 cm x 200 cm

Worktop dedicated to gluing Plexiglass, through the use of professional glues and specific UV lamps for drying and fixing.