We provide solutions that meet the major needs of the automotive sector, always keeping functionality and lightness in mind.

| Top machining |

Mold construction, Wire EDM, Milling, Turning, Microdrilling EDM, Grinding, Blanking, Adjustment, Grinding, Boring, Threading, Tapping

|

|---|---|

| erosion max |

Wire erosion MAX 600 X 400

|

| Max milling |

2000X800

|

| Other processes |

Design metal details construction

|

| Operating sectors |

Automotive, Household appliances, Oil&gas (membranes for coupling joints), Aeronautical, Electrical, Electromechanical

|

| Production area | 2500 m² |

| Employees | 35 |

| Metals/Materials |

Steels, Special Steels, Aluminum, Bronze, Iron, Brass, Special Metals

|

| Favorite lots |

Single piece, small series, large lots, periodical series

|

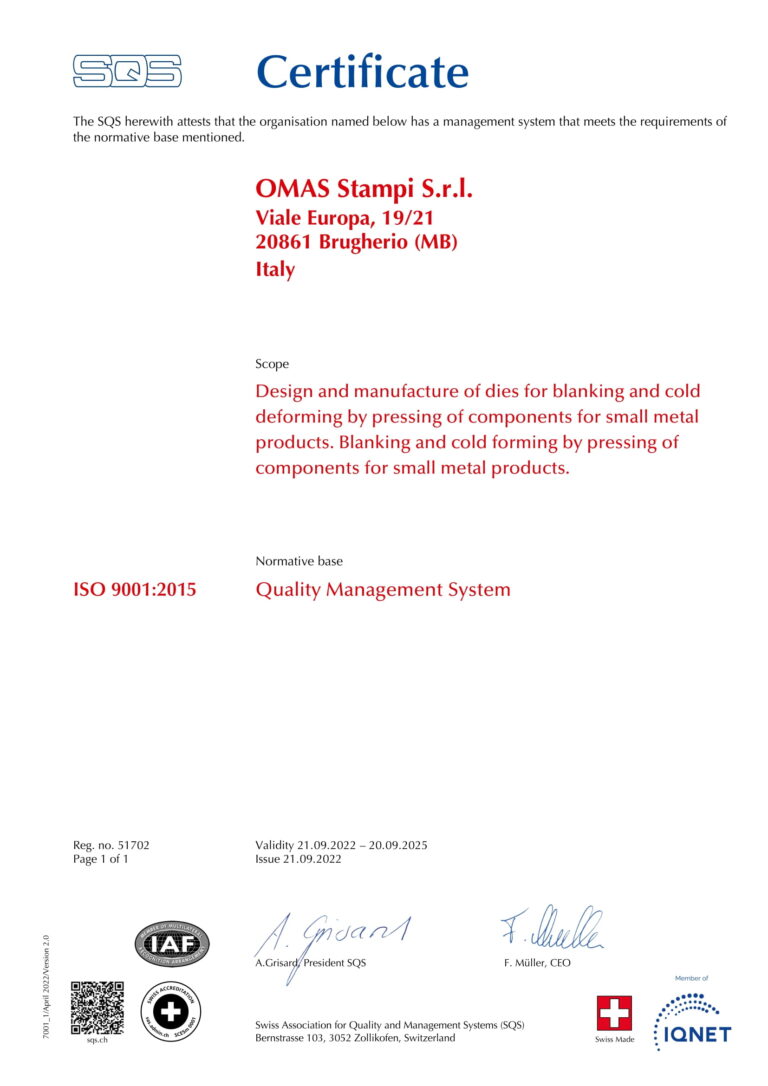

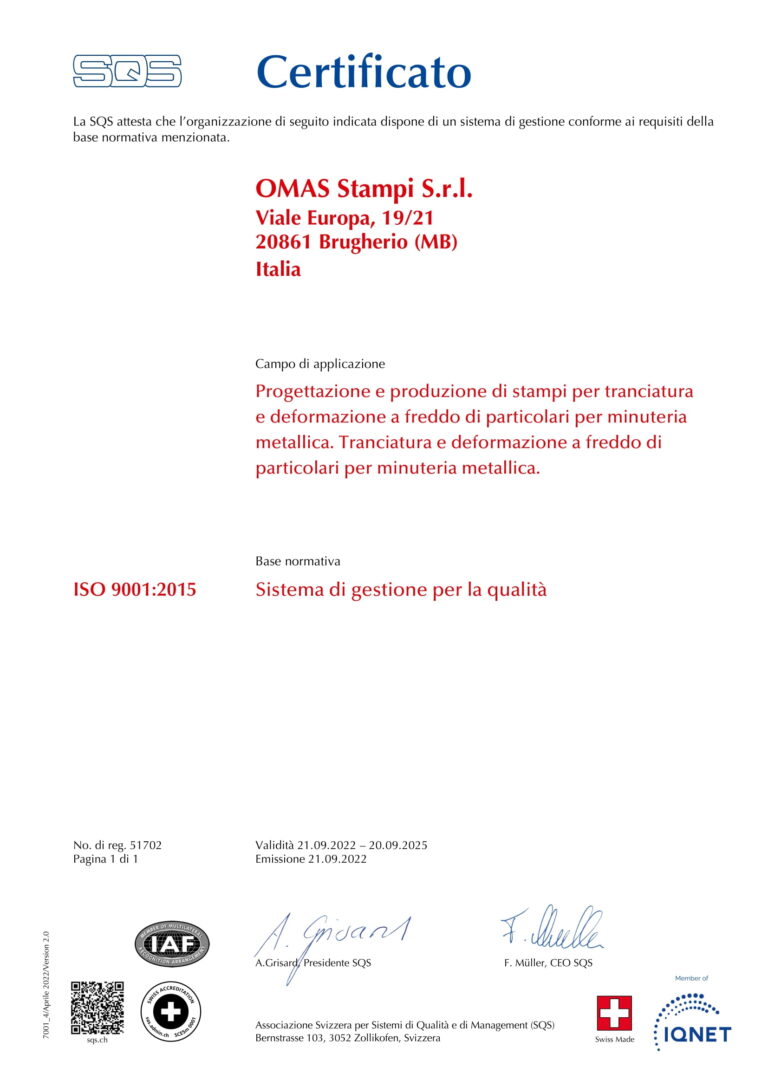

| Certifications |

IATF 16949:2016 - ISO 9001:2015 - ISO 45001

|

La OMAS Stampi srl has been present since 1973 on the market for the design and construction of molds and the production of metal parts.

Ours is a well-established, highly professional industrial reality that employs about 40 employees and carries out its business in an office of about 2500 square meters. in Brugherio.

The technological heart is represented by the Wire Erosion department (made up of 4 machines, Charmilles and Sodick) capable of producing the most complex pieces in a short time.

OMAS STAMPI is equipped with cutting-edge milling machines and machining centers, to be able to perform milling work on the following materials: steel, steel, stainless steel, iron, bronze and aluminum.

OMAS STAMPI carries out EDM micro-drilling operations, or by electro-erosion, in order to work even the hardest metals and perform precise and deep holes.

In our workshop we have milling and grinding machines suitable for the creation of molds and precision mechanical parts.

For years, with great passion and experience, we have been committed to ensuring that our products fully satisfy the requests of customers with whom we consider it a priority to establish a solid and lasting relationship of trust.

In the aeronautical sector we distinguish ourselves for the execution of precision machining and the creation of metal parts, based on customer specifications.

We carry out quality workmanship for all furnishing sectors.

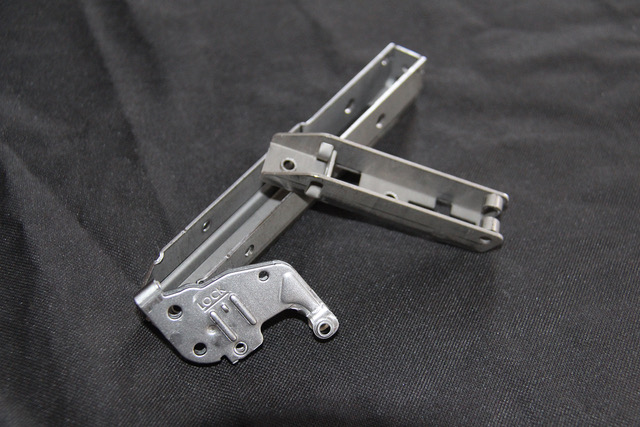

We provide solutions that meet the major needs of the automotive sector, always keeping functionality and lightness in mind.

Our experience allows us to work for various sectors, including the electrical sector, for which we manufacture numerous metal parts.

We provide tailor-made solutions for the household appliances sector, to ensure the durability of the metal parts we manufacture.

OMAS Stampi is present on various markets and operates in various sectors, the most important of which are electromechanical, electrical and household appliances.

OMAS Stampi is also active in the energy sector.

Since our company is also active in the energy sector, in recent years we have been working to offer our processes also to the wind sector.

We perform precision machining for the mining sector.

We provide ad hoc solutions for the railway sector, to ensure the durability of the parts we make over time.

We are able to supply metal parts and perform precision machining aimed at the plant engineering sector.

Our team of technicians performs precision machining for the mechanical sector.

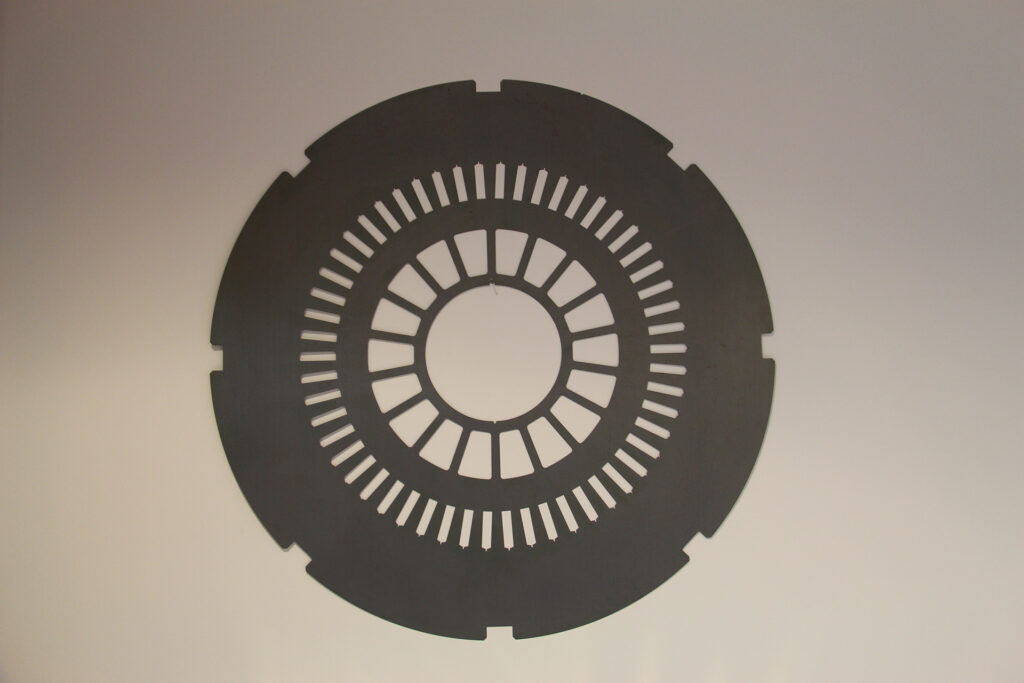

For the OIL & GAS sector we mainly produce membranes for coupling joints.

In addition to the OIL & GAS sector, we also supply metal parts for the oil sector.

Over the years we have specialized and invested in cutting-edge technologies, to achieve quality workmanship for the mold making sector.

We supply metal parts and perform precision machining aimed at the mechanical transmission sector.

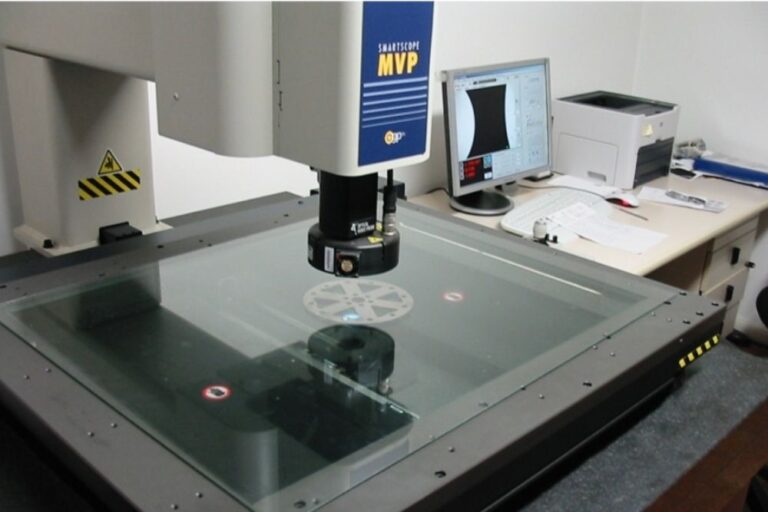

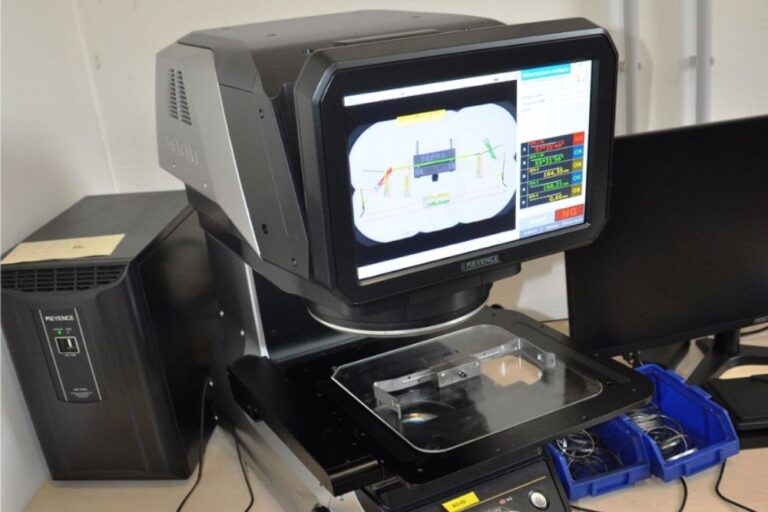

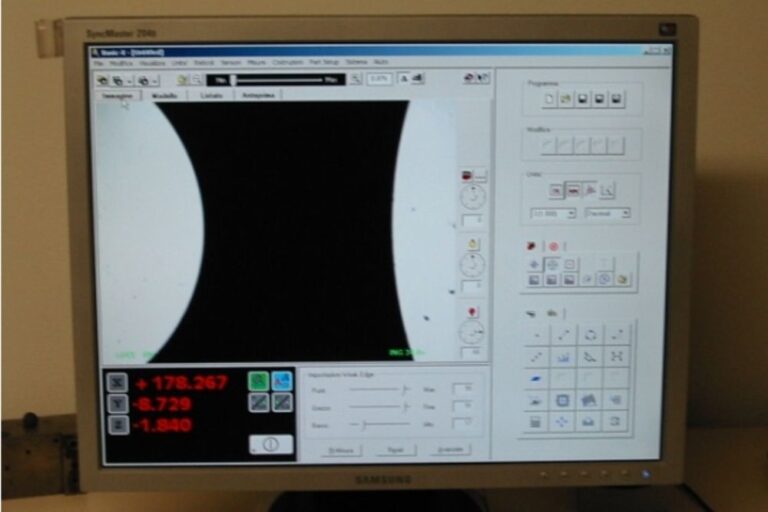

Our laboratory has all the measuring instruments necessary to guarantee the highest quality:

OMAS Stampi has the certificate for Quality Management System compliant with the automotive standard IATF 16949: 2016 and the international standard ISO 9001: 2015.

It also has the certificate for the Health and Safety Management System compliant with the international standard ISO 45001.

Omas Stampi has given added value to its products and services by guaranteeing all its customers one quality standards e high security.

Specifically, our company has decided to design and implement a Management System that complies with the requirements of international standards UNI EN ISO 9001: 2015 e UNI EN ISO 45001: 2018, to better structure its production processes and optimize its organization.

Omas Stampi is also certified according to the IATF 16949 standard, meeting the needs of its customers, especially the automotive sector.

The training of young talents is a primary objective. With great pride in 2019 we have joined the ITS Lombardia Mechatronics Foundation as participating members.

The ITS (Higher Technical Institutes) are institutions that provide post-diploma courses that meet the business demand of new ed high technical skills and technology to promote innovation processes.

The courses are built through a shared planning and participated by all the subjects that make up the ITS Foundations (companies, schools, universities, training and research institutions, associations).

text