| Top machining |

Milling, Turning, Adjustment, Marking, Threading, Tapping, Drilling, Testing

|

|---|---|

| Max turning |

D.300 L.600

|

| Max milling |

1600X500

|

| Other processes |

Milling details machined from solid

|

| Operating sectors |

Aeronautics, Equipment, Vintage cars and motorbikes, Automotive, Energy, Mechanical, Medical, Hydraulic, Packaging, Racing, Other sectors...

|

| Production area | 500 m² |

| Employees | 6 |

| Metals/Materials |

Steels, Special Steels, Aluminum, Aluminum Alloys, Bronze, Iron, Brass, Copper, Titanium, Special Metals, Polymers

|

| Favorite lots |

Single piece, small series, large lots, periodical series

|

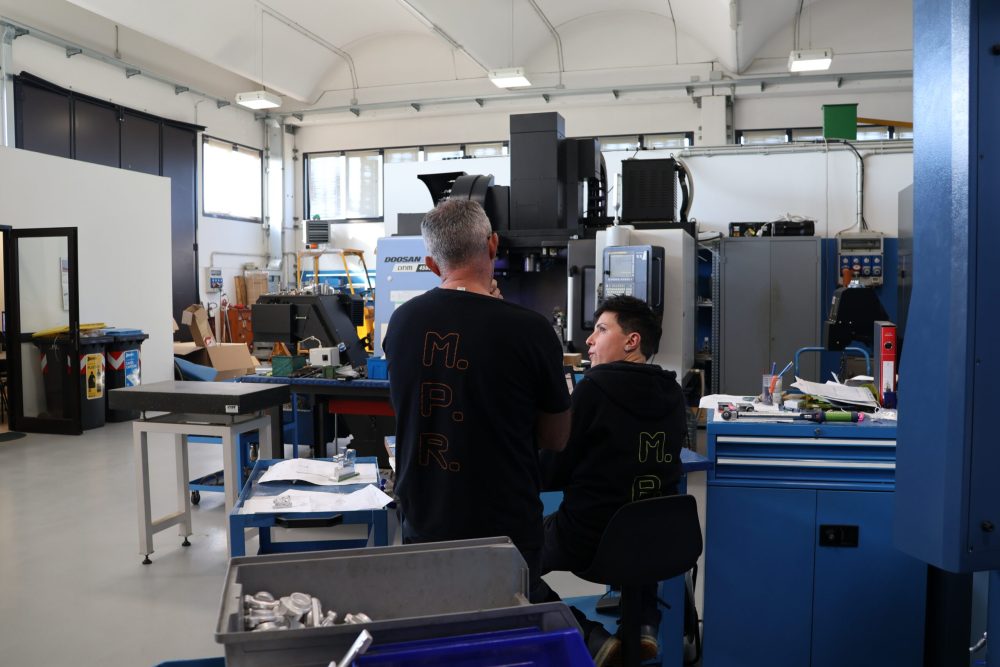

MPR Rome was founded in 2006, recording constant growth over the years both in terms of turnover and technological implementation, opting for the conversion of profits into reinvestments of equipment and training of its employees.

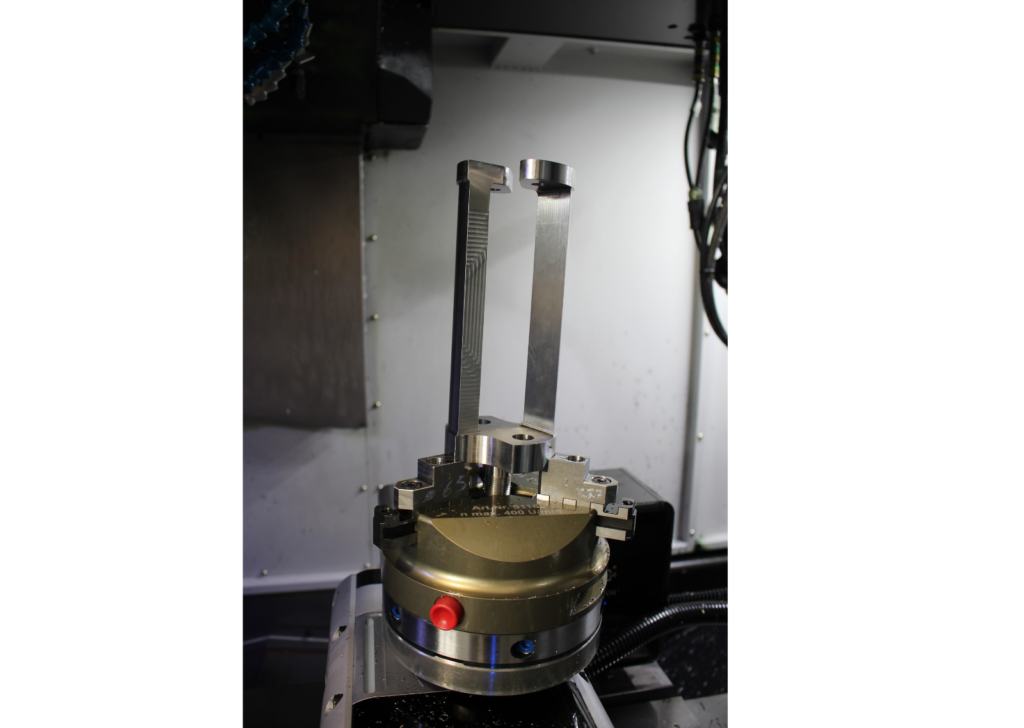

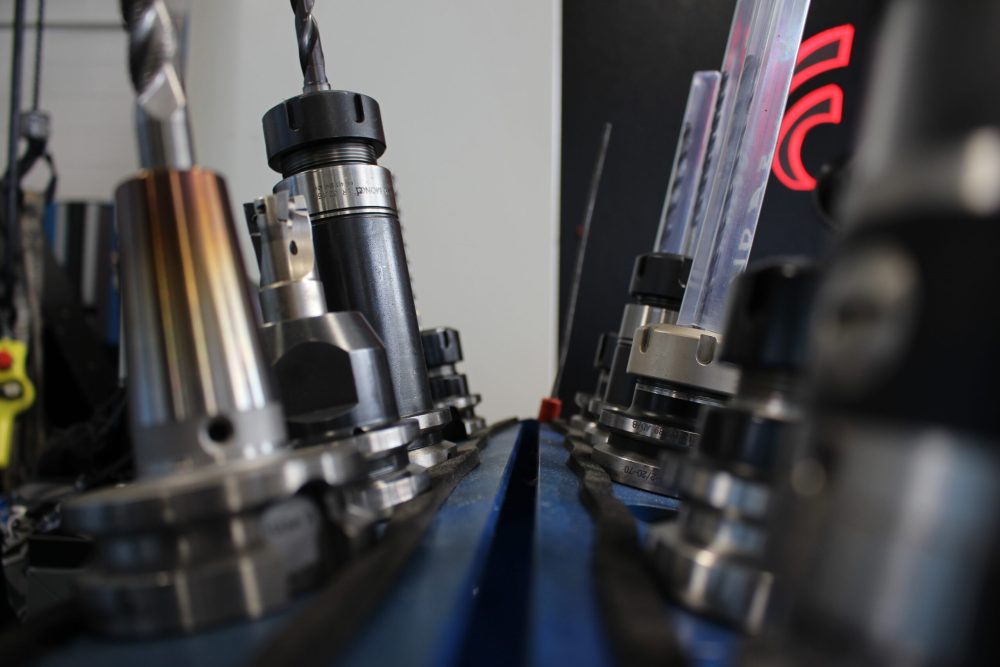

The company makes use of the latest generation CNC machines, necessary to solve the various problems associated with the machining of complex parts, and to obtain excellent quality precision.

The high operational flexibility allows the company to work individual parts or in series, to respond adequately to the requests of individual customers.

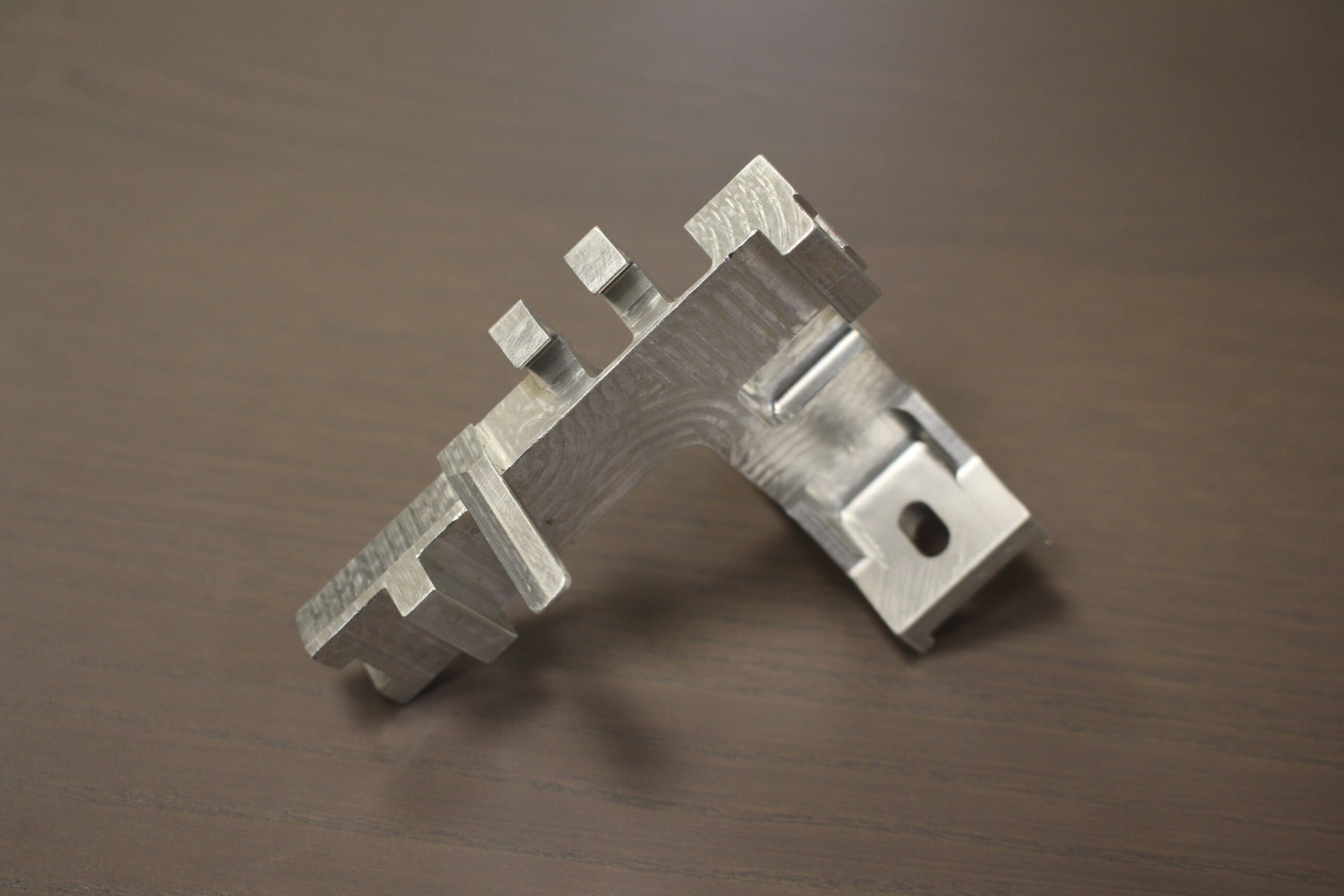

Clutch actuator

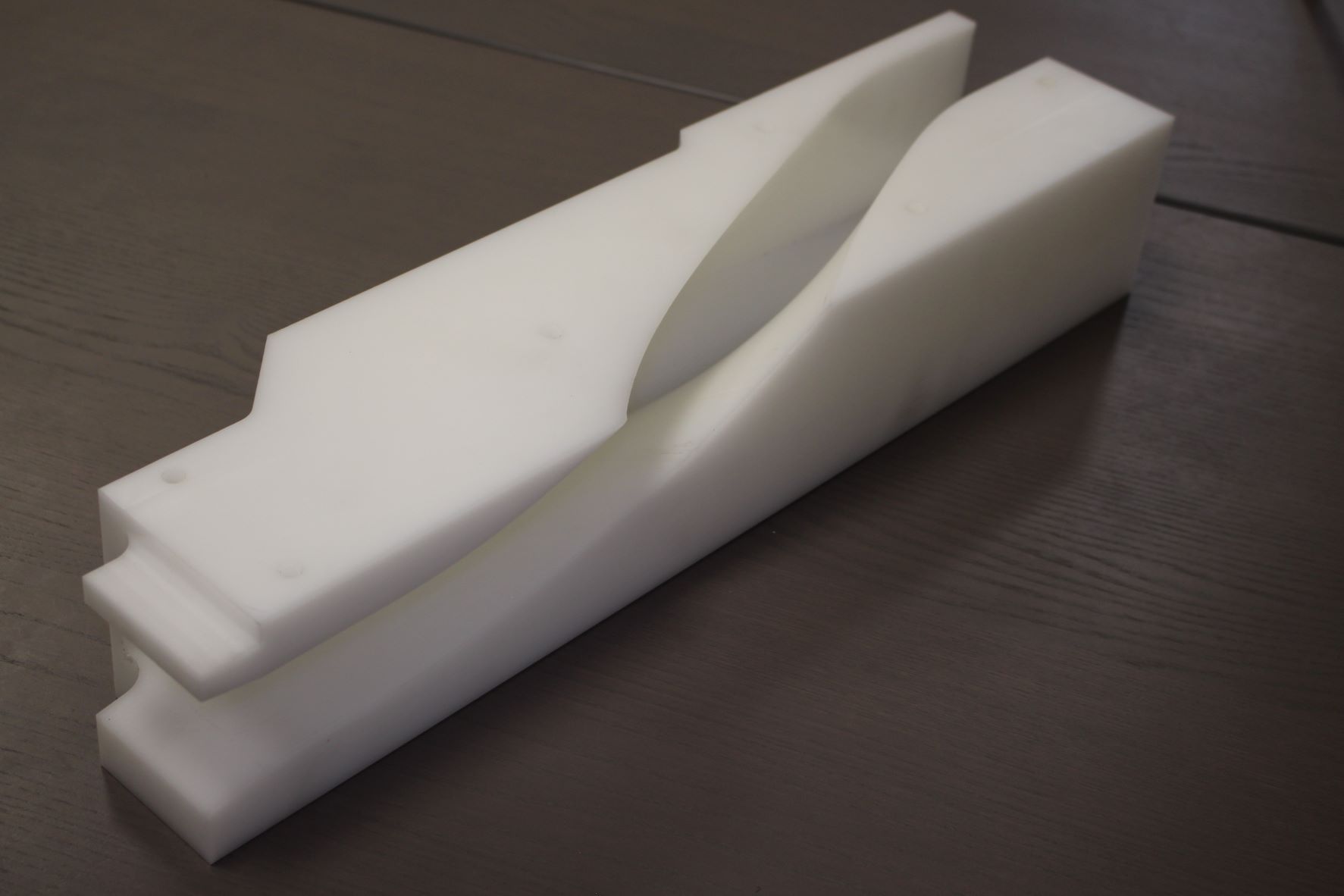

Details for packaging machines

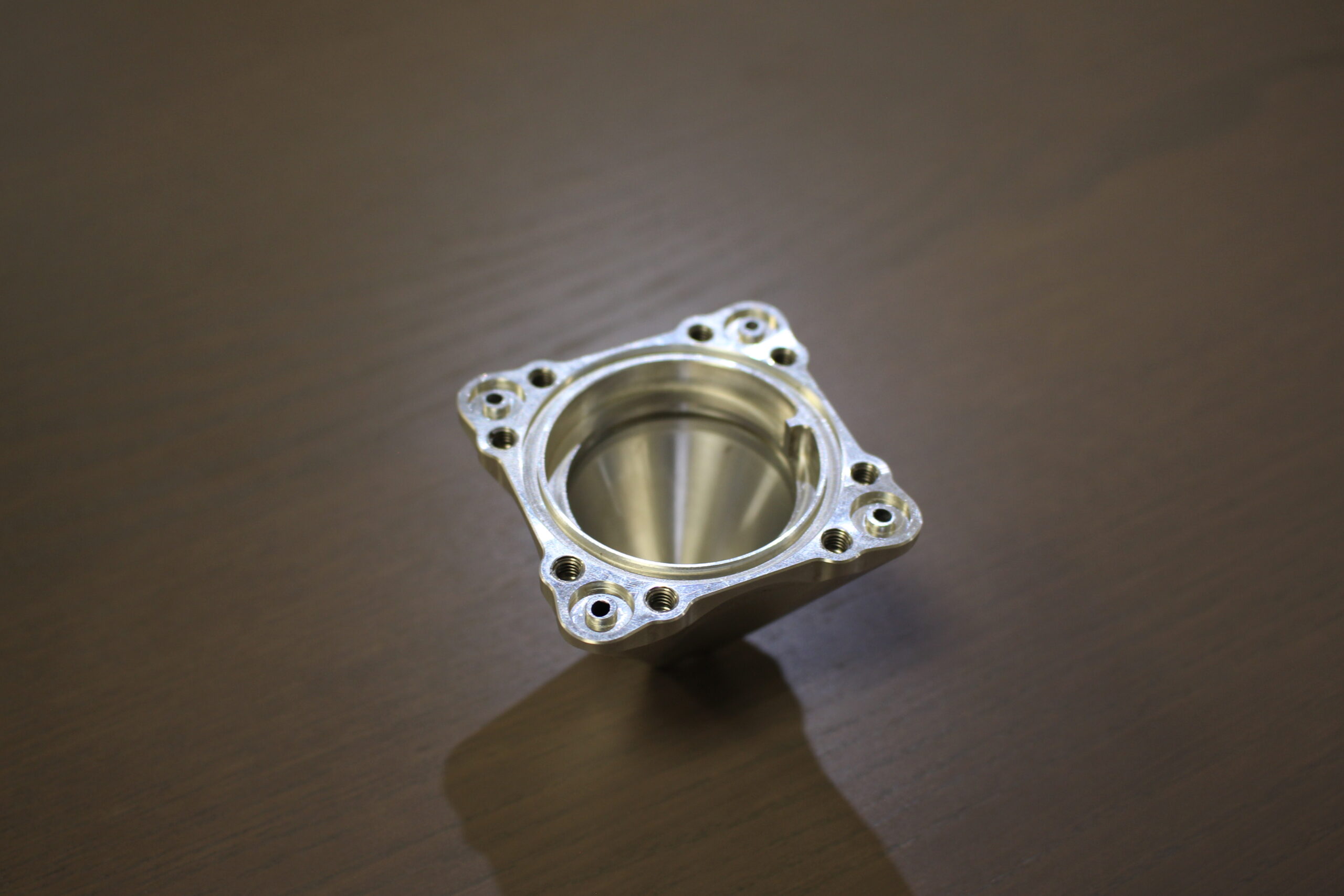

Propeller turner

Head for laser printer

Motorcycle gear lever

Sector for packaging machines

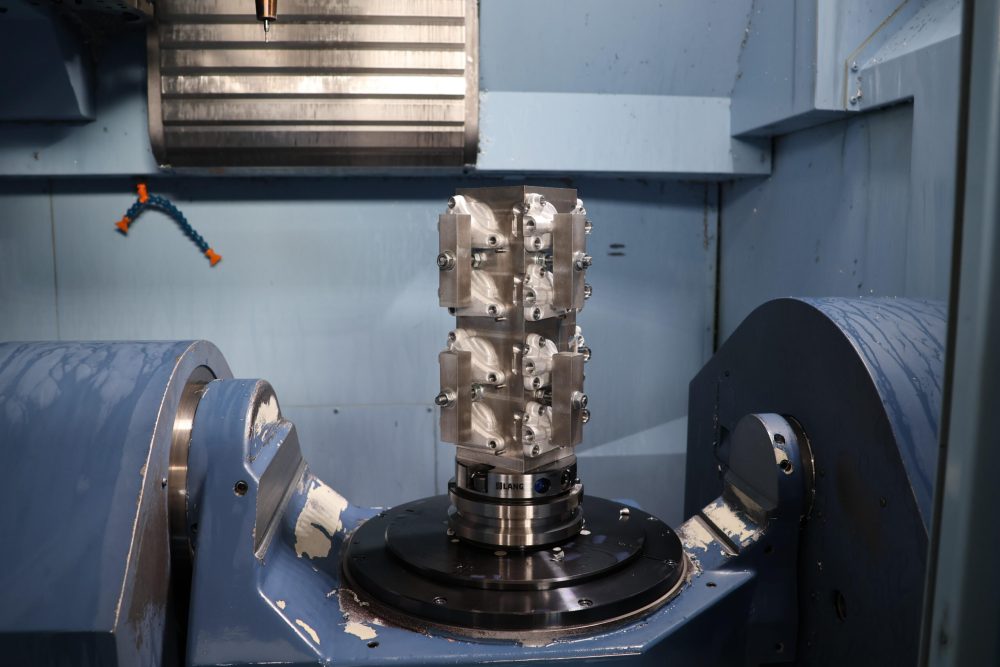

The presence in the workshop of machines capable of performing milling operations with 4 and 5 axes, allows us to adequately respond to the needs of each customer.

Thanks to the use of 3/4 axis CNC machines plus a 5 axis lathe, we are able to carry out numerous processes for applications used in various sectors.

Among the processes performed in MPR Rome there is the adjustment, a cold working of the metals that we want directly to the adjustment bench present in the workshop.

The marking or punching of each piece with the univocal lot code allows the reference order to be identified on the production lot, up to generating the entire traceability of the manufacturing processes, from the initial solid to the finished piece.

We carry out testing of the mechanical parts that we produce, using highly technological machinery that allows us to guarantee the functionality and robustness of the machined parts.

Why choose us?

MPR Rome boasts a young, highly qualified and helpful staff.

We are also equipped with latest generation 3/4/5 axis CNC machines, we carry out cad/cam programming and quality control with 3D instrumentation, and we work different types of materials: steel, stainless steel, titanium, aluminum, ergal,

Machine name: Matsuura machining center 5 axes 10 pallets

Machine name: Machining center Fagima 5 axes

Machine name: Doosan 5 axis machining centre

Machine name: Doosan 4 axis lathe

Our company is made up of operators assigned to CNC machines, with a strong orientation towards problem solving.

This allows them to carry out high precision machining and to guarantee the quality of each individual product made.

We make details for:

motogp, SBK, F1 &

extreme packaging