| Top machining |

2D Laser Cutting, Combined Cutting, Tube Laser Cutting, Punching, Robotic Bending and Bending, 3D Laser Welding and Cutting, TruDisk Aesthetic Welding, Manual Welding, Robotic Welding, Customized Finishing, Satin Finishing, Deburring, Turning, Milling

|

|---|---|

| Other processes |

Surface finishing, marking, treatments (cataphoresis, polishing, painting)

|

| Services and supplies |

Final delivery to the customer with own means of transport on national territory and organization of World Wide transport.

|

| Operating sectors |

Aeronautics, Agriculture, Food, Urban furniture, Equipment, Automotive, Access controls, Air treatment, Other sectors...

|

| Work area | 24.000 m² of which 18.000 are covered |

| Employees | 130 |

| Metals/Materials |

Steels, Stainless steel, Aluminium, Iron

|

| Favorite lots |

Small series, large lots, periodic series

|

| Certifications |

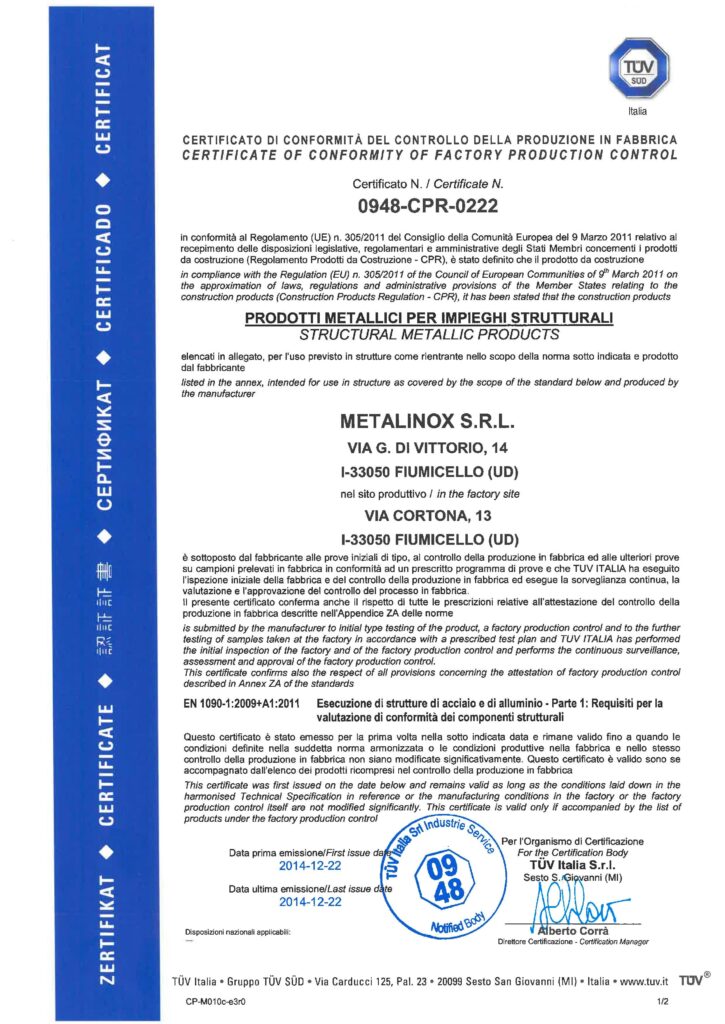

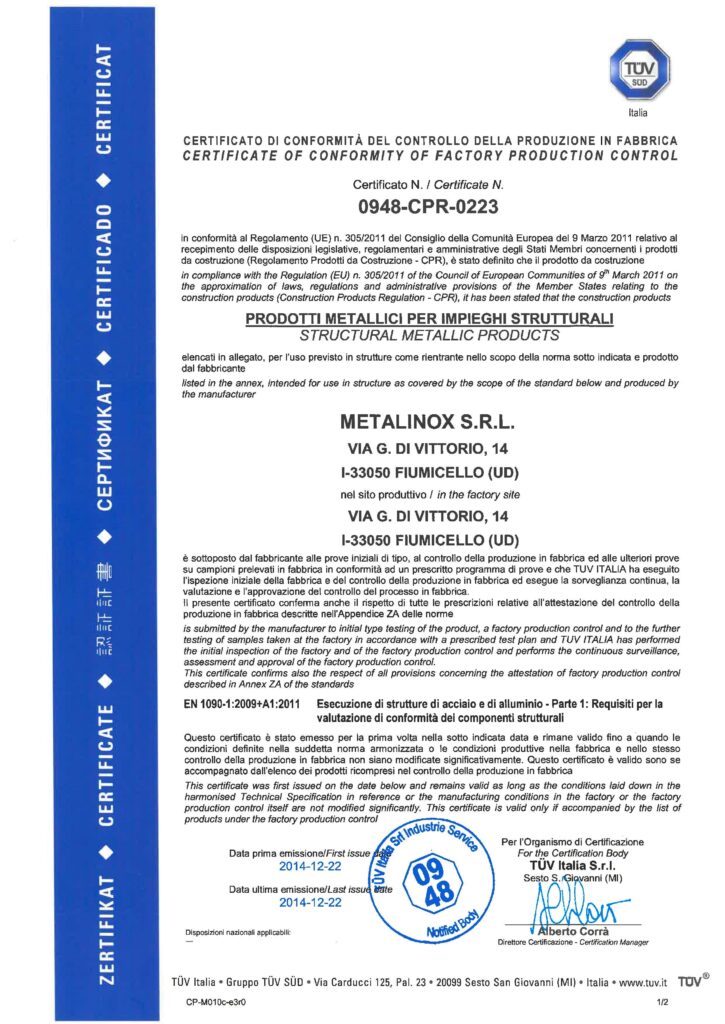

UNI EN ISO 9001:2015, ISO 3834-2:2021, 0948-CPR-0222, 0948-CPR-0223

|

Kostwein Metalinox SRL: “made in Italy” steel present in 22 countries around the world.

What would design be without technology? To those who ask the question, Kostwein Metalinox SRL responds with high-profile products, designed to last over time, wherever they are intended.

From the benches and turnstiles for the Paris Metro, to the tensile structures of the KAUST mega-project for the University of Jeddah in Saudi Arabia, to the pharaonic interiors of Fincantieri cruise ships, to the versatile exhibition displays of the Hugo Boss chain in Germany. A stainless passion that in 42 years has allowed us to export our knowledge to 22 countries around the world.

Processing carried out on the piece: Design, laser cutting and 3D laser cutting, molding, press bending, laser welding, satin finishing

Processing carried out on the piece: Design, tube laser cutting, press bending

Processing carried out on the piece: Design, laser cutting of tubes

Processing carried out on the piece: Design, tube laser cutting, laser cutting, laser welding, robotic satin finishing

Processing carried out on the piece: Design, laser cutting, press bending

Processing carried out on the piece: Design, laser cutting, press bending, robotic laser welding, manual and robotic satin finishing

Processing carried out on the piece: Design, laser cutting, press bending, robotic laser welding, manual and robotic satin finishing

Example of product processed in Kostwein Metalinox SRL - For more information, contact us

Example of a Yag aesthetic welding detail that highlights its peculiarities.

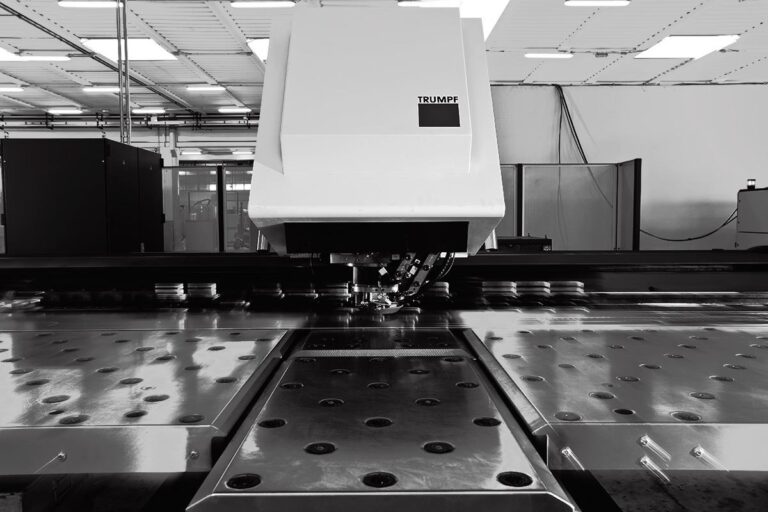

Kostwein Metalinox SRL has 5 internal punching centres: 3 stations with automatic palletisation (max format 4000 x 1500 mm) and 2 stand-alone stations (max width 6000 mm).

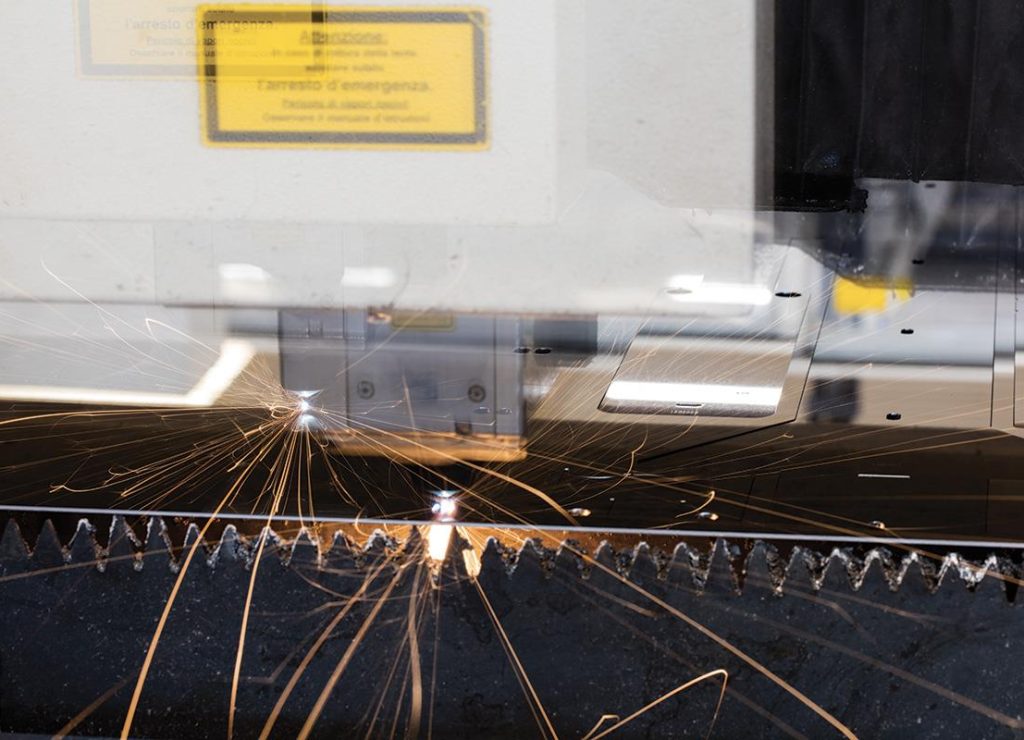

By integrating the typical functions of mechanical cutting (threading, tapping, deformation, flaring, drawing) with the functions of laser cutting, Kostwein Metalinox SRL can carry out the simultaneous processing of both the perimeter and internal parts of elements with maximum dimensions of 3000 x 16000 mm and a maximum thickness of 8 mm.

This fully automated process makes it possible to create the most diverse cutting geometries, upon customer request.

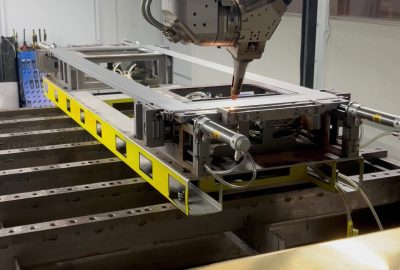

The bending department is structured on 12 manual centers and 2 automated centers with servo-assisted Cartesian robots and automatic palletizing. The workable formats reach up to 6000 mm.

Our robotic press bending cell allows us to implement, automate and improve the sheet metal working process according to the needs and times requested by the customer.

Thanks to new generation 3D laser systems, Kostwein Metalinox SRL can perform welding and cutting even on pieces that have already been completely machined, guaranteeing maximum structural resistance.

TruDisk laser technology, among the most advanced available today, combined with a robotic system, allows you to perform welds of high aesthetic value, by virtue of the extreme concentration of the laser on a very small surface.

Kostwein Metalinox SRL is proud to interpret the ancient art of welding, in creations that combine fine craftsmanship in every detail and total quality, carried out by ISO certified operators.

Kostwein Metalinox SRL has 4 anthropomorphic robots capable of serving 9 welding stations, including 3 MIG and 6 latest generation TIG.

Thanks to the high internal technological level and a consolidated network of external collaborations, Kostwein Metalinox SRL can finish its creations with the most diverse surface treatments: painting, electrolytic or hot galvanizing, brightening, electropolishing, micro-peening, pickling, passivation and others .

Kostwein Metalinox SRL can carry out satin finishing and polishing processes on any metal, even with marking upon customer request to personalize its products.

A cutting-edge technology that allows you to perform, in a single process, different functions normally divided into multiple work centers, on tubes of various thicknesses and sections, with completely customized cuts and drillings.

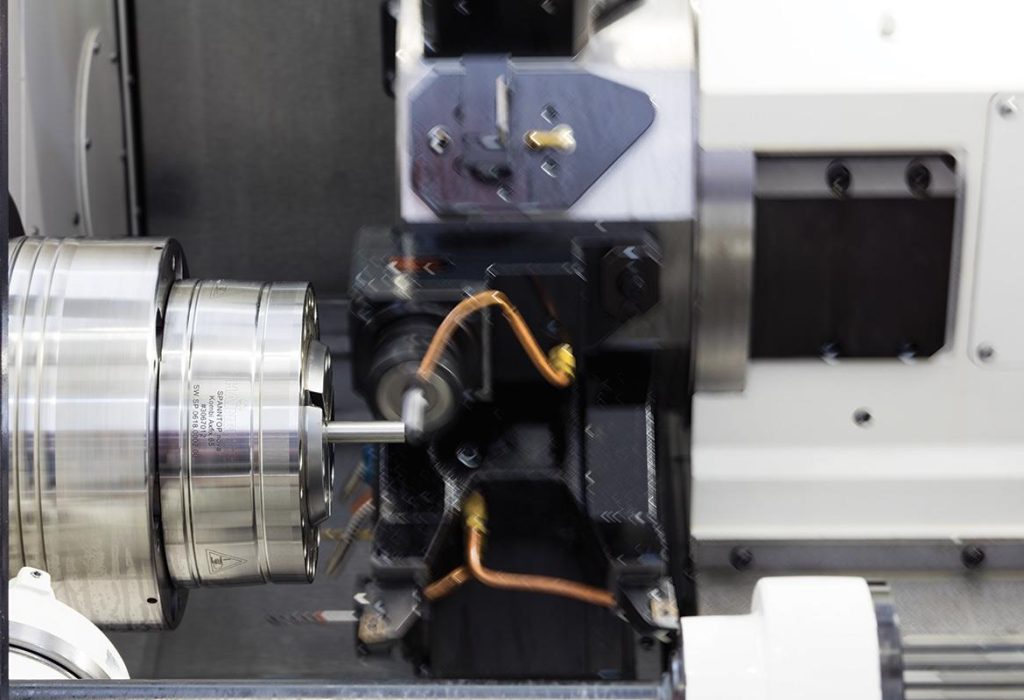

To meet the needs of each customer, Kostwein Metalinox SRL has created a turning and milling department, capable of producing metal elements directly within the company, with the utmost attention to detail.

WHY CHOOSE US?

From design, to metal selection, to the creation of the products requested by the customer, up to worldwide delivery and qualified technical assistance. With a "made-to-measure" culture born from passion and artisan tradition, a modern business organization oriented towards "made to order" and a cutting-edge vision, to overcome all the challenges of the present and future: always with an unmistakable style.

Each piece is crafted with attention and precision. Quality and attention to detail are two fundamental components in the work philosophy of Kostwein Metalinox SRL.

For Kostwein Metalinox SRL, quality is one of the fundamental company principles. In fact, it places scrupulous attention on quality control at the end of each production process by making use of qualified managers equipped with specific equipment for each examination, including the digital altimeter, digital caliper and caliper and the roughness meter to check the roughness of the material and the control of welding throat height.

Kostwein Metalinox SRL has obtained various certifications:

The Copenhagen Metro is the only one in Denmark, consisting of 4 lines. The first two lines of the network were inaugurated in 2002, followed over the years by the third line, which was inaugurated in 2019 and the fourth line in 2020.

Kostwein Metalinox SRL intervened in the construction of the handrails, skylights and balustrades.

St. Giles, “The Now Building”, is an innovative and majestic building located in central London. It offers a new space for storytelling, art, fashion, music, film, through technology and entertainment that come to life in new and inspiring ways.

Kostwein Metalinox SRL was responsible for the construction of the external architectural cladding.

“The Spiral” also known as “66 Hudson Boulevard” is a 66-story skyscraper, under construction in Hudson Yards, Manhattan, New York. The characteristic that distinguishes it is that on each floor the terraces will rise in a spiral, creating vertical gardens that will surround the building.

Kostwein Metalinox SRL was responsible for the construction of the lattice balustrades and handrails.

Inaugurated in 1900, the Paris Metro is the third largest in Europe and transports almost 1,5 billion people every year.

Kostwein Metalinox SRL intervened to cover the control systems in all accesses. A huge challenge accepted and completed with enthusiasm by the company, in harmony not only with the functional needs of the project, but also with the aesthetic characteristics of the refined design of the "Métro".

With 170 meters of height and 50 floors, the Tour Odéon is the tallest residential building in Monte Carlo and the

second tallest skyscraper in Europe.

Kostwein Metalinox SRL contributed to this extraordinary architectural project, providing 62 km of balconies, executed with cutting-edge technologies, using 400 tons of stainless steel. A large-scale and exceptionally high-level intervention, which began in July 2013 and was completed in June 2015, six months before the inauguration of the work which today stands out in the city skyline.

Kostwein Metalinox SRL, thanks to its experience and

its organization, can respond quickly to every request, as in the case of set-up

of the Victoria Gate shopping center designed and built in cooperation with Se-Austria

GmbH&Co. KG.

From receipt of the order, which included painted products for a total of approximately 24 tons of steel with cataphoresis treatment, transformed within the Kostwein Metalinox SRL factory, to delivery, just 5 weeks passed.