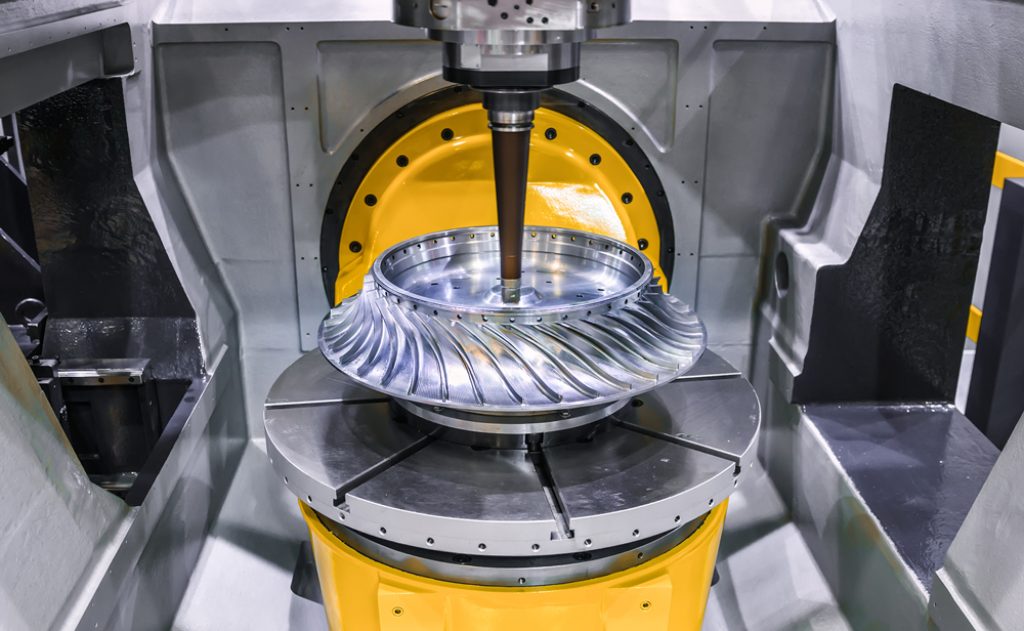

| Top machining |

Boring, gear cutting, milling, grinding, turning, deep drilling

|

|---|---|

| Max turning |

Turning from Ø10 to Ø1400

|

| Max milling |

|

| Other processes |

Surface treatments, Heat treatments

|

| Operating sectors |

Aeronautical, Railway

|

| Operating area | m² |

| Employees | |

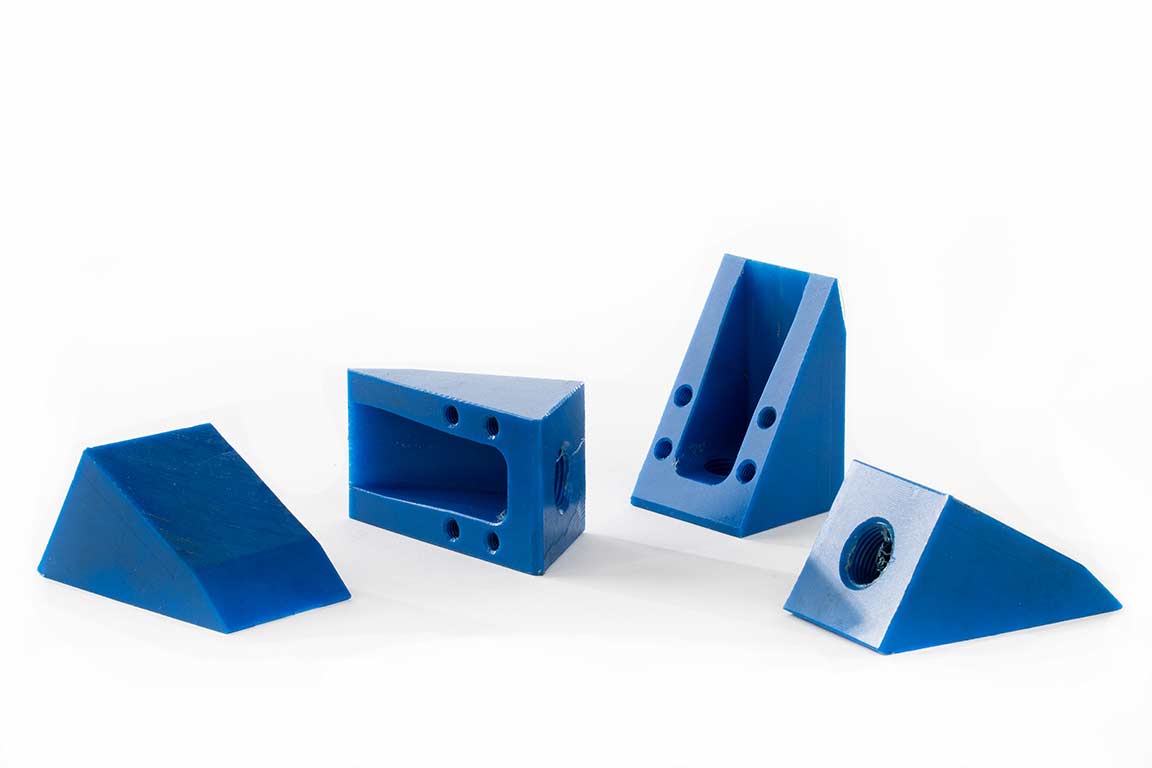

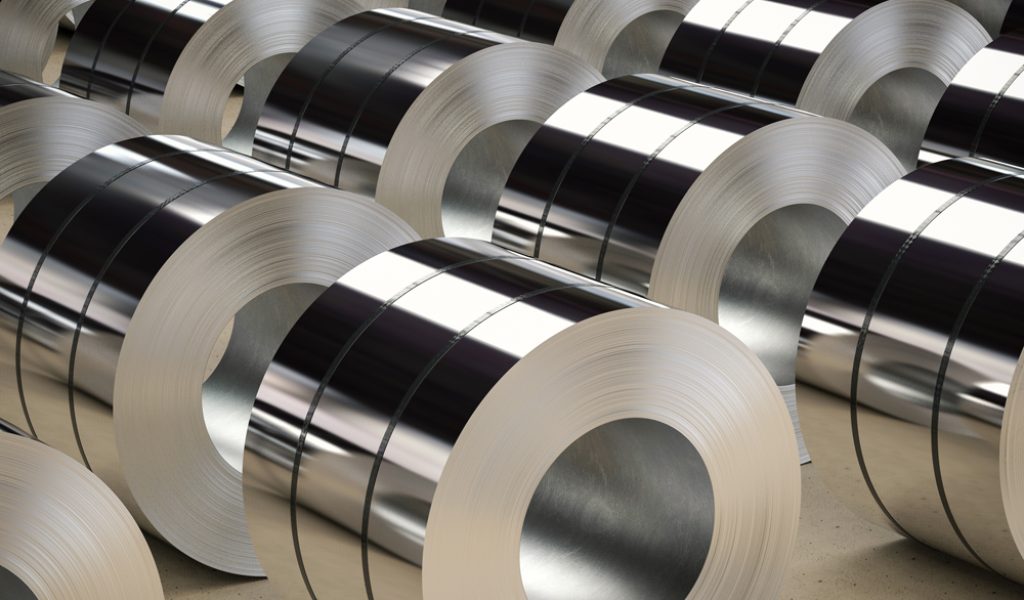

| Metals/Materials |

Steel, Aluminium, Ferritic stainless steel, Bronze, Brass, Plastic materials

|

| Favorite lots |

|

| Certifications |

UNI EN ISO 9001: 2015

|

Metalcontrol is an Emilia-based company that has been carrying out mechanical boring, toothing, milling, grinding, turning, deep drilling and surface treatments on all types of steel since 1997: construction, stainless and non-stainless steel, brass, aluminum, plastics, stainless steel and ferritic stainless steel.

Metalcontrol stands as an active partner for every production requirement and supports the customer at every stage: from design to delivery, making use of a team of specialists capable of satisfying every need and offering a complete 360° service.

With over 30 years of experience and continuous and constant technological updates we are able to deliver the finished product in all its parts starting from the customer's technical drawing. We work all types of construction steel, stainless and non-stainless, brass, bronze, aluminum, plastic materials, stainless steel and ferritic stainless steel for stability purposes, scales and in the aeronautical field.

With over 30 years of experience and continuous and constant technological updates we are able to deliver the finished product in all its parts starting from the customer's technical drawing. We work all types of construction steel, stainless and non-stainless, brass, bronze, aluminum, plastic materials, stainless steel and ferritic stainless steel for stability purposes, scales and in the aeronautical field.

With over 30 years of experience and continuous and constant technological updates we are able to deliver the finished product in all its parts starting from the customer's technical drawing. We work all types of construction steel, stainless and non-stainless, brass, bronze, aluminum, plastic materials, stainless steel and ferritic stainless steel for stability purposes, scales and in the aeronautical field.

With over 30 years of experience and continuous and constant technological updates we are able to deliver the finished product in all its parts starting from the customer's technical drawing. We work all types of construction steel, stainless and non-stainless, brass, bronze, aluminum, plastic materials, stainless steel and ferritic stainless steel for stability purposes, scales and in the aeronautical field.

With over 30 years of experience and continuous and constant technological updates we are able to deliver the finished product in all its parts starting from the customer's technical drawing. We work all types of construction steel, stainless and non-stainless, brass, bronze, aluminum, plastic materials, stainless steel and ferritic stainless steel for stability purposes, scales and in the aeronautical field.

With over 30 years of experience and continuous and constant technological updates we are able to deliver the finished product in all its parts starting from the customer's technical drawing. We work all types of construction steel, stainless and non-stainless, brass, bronze, aluminum, plastic materials, stainless steel and ferritic stainless steel for stability purposes, scales and in the aeronautical field.

Metalcontrol makes use of for the workings of boring of the following machines:

Metalcontrol makes use of for the workings of teeth of the following machines:

Metalcontrol makes use of for the workings of milling of the following machines:

Metalcontrol carries out the following processes of correction:

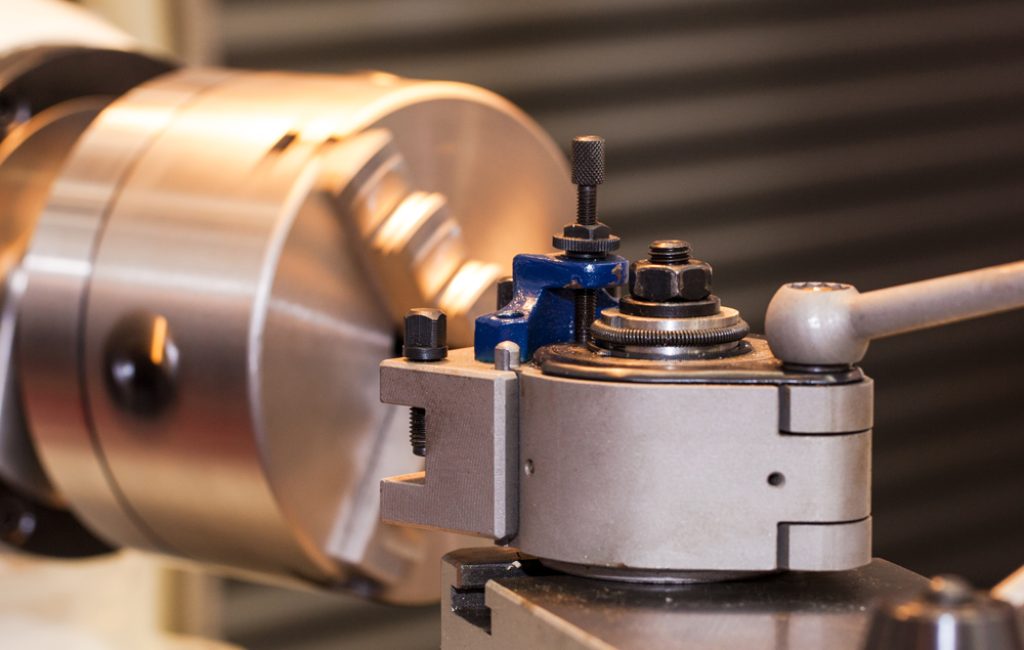

Metalcontrol makes use of for the workings of turning of the following machines:

Metalcontrol makes use of for the workings of deep punctures of the following machines:

Metalcontrol performs the following treatments:

"Our company aims to make the most of the products it manufactures, therefore various regulations are imposed for processing and production. All this with the aim of providing each customer with products guaranteed over time in terms of effectiveness and construction quality. Last but not least, all this is done in the most ecological way possible, firstly by making the best use of renewable energy and secondly by investing in the production area to reduce the environmental impact of each project. ”

Federica Marmiroli – Senior Partner

We offer an accurate "ad hoc" assistance service in optimizing the projects supplied or to create them to measure from scratch.

We have a large warehouse of materials in order to guarantee the best processing times.

Work environments suitable for the assembly of each mechanical part in order to guarantee a complete service.

Each component produced is finished and painted to ensure durability and perfect mechanics for its purpose

"Turnkey" delivery, thanks to our network of means of delivery, punctuality is guaranteed throughout Italy.

Support for the entire life span of the products supplied, from installation to maintenance operations.

Machine name: Amada Disc saw CMII-100DG

DATA: The automatic circular saw CMB 100 CNC AMADA, thanks to its convenient operation and its frequency-controlled rotation speed regulation, meets the highest demands in terms of cutting accuracy and machining capacity, more economically than others cutting and trimming processes. With the CNC control, the cutting values and the different cutting length/quantity combinations can be predefined, whereby the machine is also interesting for smaller series. Thanks to the use of special single-use carbide blades, only 2 mm thick, in combination with minimal lubrication and cooling, excellent smooth cutting surfaces and burr-free cutting sections can be achieved.

An oblique loading magazine on the loading side and an automatic classification of the initial cut and the residual part.

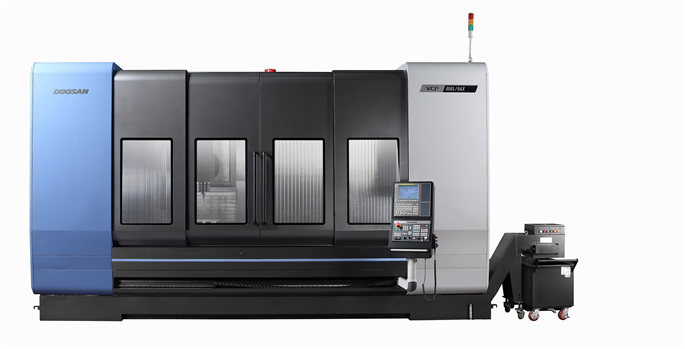

Machine name: Doosan DNM 6700 L

DATA: Building on the proven and successful history of the DNM and DNM ll series, the new version of the DNM series boasts even greater reliability and performance. Furthermore, the new series provides grease lubrication of the guide roller for greater environmental compatibility. The design concepts of the DNM 4500/5700/6700 series are high speed, high rigidity and suitability for universal applications. Standard features are the largest machining space in its class, direct drive spindle, roller guides and thermal error compensation to provide optimum accuracy.

Machine name: Doosan PUMA 700 XLY

DATA: The turning centers of the PUMA 600/700/800 series are the most powerful machines in their category. Designed for heavy and interrupted cutting, they maintain exceptional qualities of stability and precision over time. This machine is capable of withstanding high material removal rates which, combined with fast turret positioning, ensures unrivaled cycle times when real performance is of the essence. The three variants are all also available with driven tools and Y axis for a complete and competitive range.

[L] Long version; [XL] extra long version [Y] 4 axis version with driven tools and Y axis

Machine name: OKUMA VTM 120

DATA: Optimal for heavy machining: The robust five-axis vertical turning/milling centers of the VTM-YB series make it the ideal machine tool if you want to machine complex workpieces. The machining tools of this series, which can be used for both turning and milling, are clamped in a swiveling spindle (B-axis) with a large rotation range. The linear strokes, equipped with large flat guides, optimal for heavy machining, ensure a large working space.

Machine name: Doosan VCF 850L-SR

DATA: 5-axis moving column machining center with swivel head, integrated rotary table and CNC AT YOUR CHOICE BETWEEN Heidenhain TNC-640 HSCI or Fanuc 31-iB5

Machine name: Doosan PUMA SMX 3100 ST

DATA: Doosan SMX: the new frontier of Multi-Tasking turning centers with an orthogonal structure. Machine with an ergonomic design and great structural integrity, a guarantee of stability and precision, it comes with a tilting head [B axis] and a 12.000 rpm spindle, opposing spindles and a 300(±150) mm Y stroke. The supply is completed by a 40-place magazine (opt.80), servo controlled steady rest and linear tool setting system.

Machine name: Doosan PUMA SMX 3100 LS

DATA: Doosan SMX: the new frontier of Multi-Tasking turning centers with an orthogonal structure. Machine with an ergonomic design and great structural integrity, a guarantee of stability and precision, it comes with a tilting head [B axis] and a 12.000 rpm spindle, opposing spindles and a 300(±150) mm Y stroke. The supply is completed by a 40-place magazine (opt.80), servo-controlled retractable rest under the main spindle and linear tool setting system.

The new L version guarantees 2540mm of maximum turning length

S: secondary spindle

Machine name: Doosan Puma MX 2600 ST

DATA: Integrated turning center with continuously adjustable upper milling head and equipped with Y axis, possible motorized lower turret, servo-controlled tailstock or second spindle. The upper head is powered by a tool magazine and can turn or mill by orienting itself on different angles. Even extremely complex parts can be completely finished without further reworking.

Machine name: Doosan Mynx 7500

DATA: Vertical machining centers characterized by sliding on prismatic guides in all axes, for heavy use in the presence of tough materials. On the market for 15 years, they have earned an excellent reputation for precision and rigidity. The latest series has paid particular attention to ergonomics and completeness in the equipment. All models are optionally equipped with numerical controls or Doosan Fanuc i-Series or Heidenhain iTNC 530 of the latest generation. All three models are available in both ISO-40 and ISO-50 versions and with a wide range of accessories to better adapt to all production needs.

Among the company objectives there is the greater involvement of the staff in order to make the manufacturing process more fluid, but also the creation of a specialized Technical Department for the creation of new products.

The company's success is closely related to an "integrated" management of the processes necessary for the realization of what is required by customers, both in terms of product conformity and in terms of service.

The constant control of quality standards makes Metalcontrol at the forefront both for the measurement methods adopted and applied and for the high precision instrumentation.

Metalcontrol has obtained the following certifications

which attest: