| Top machining |

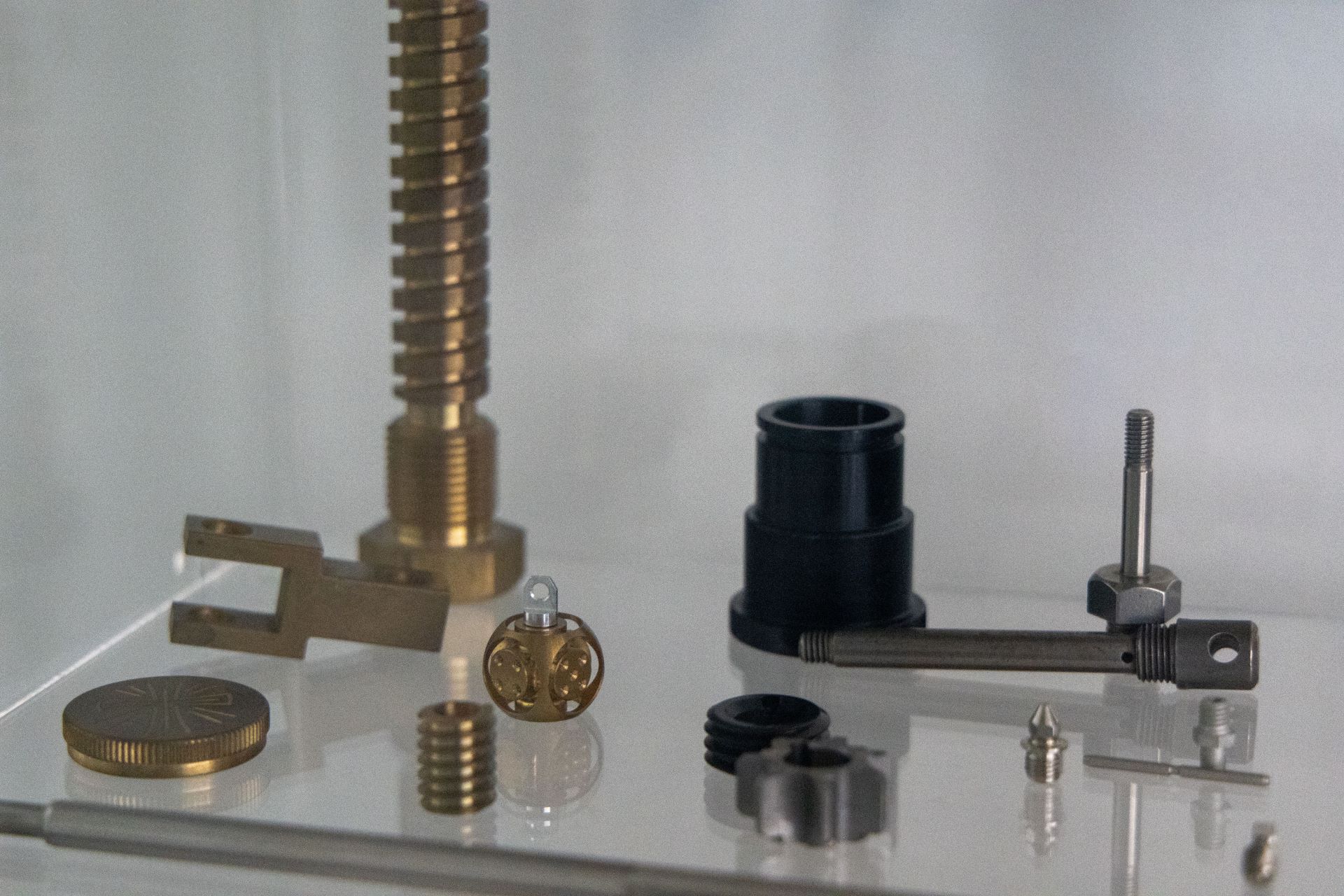

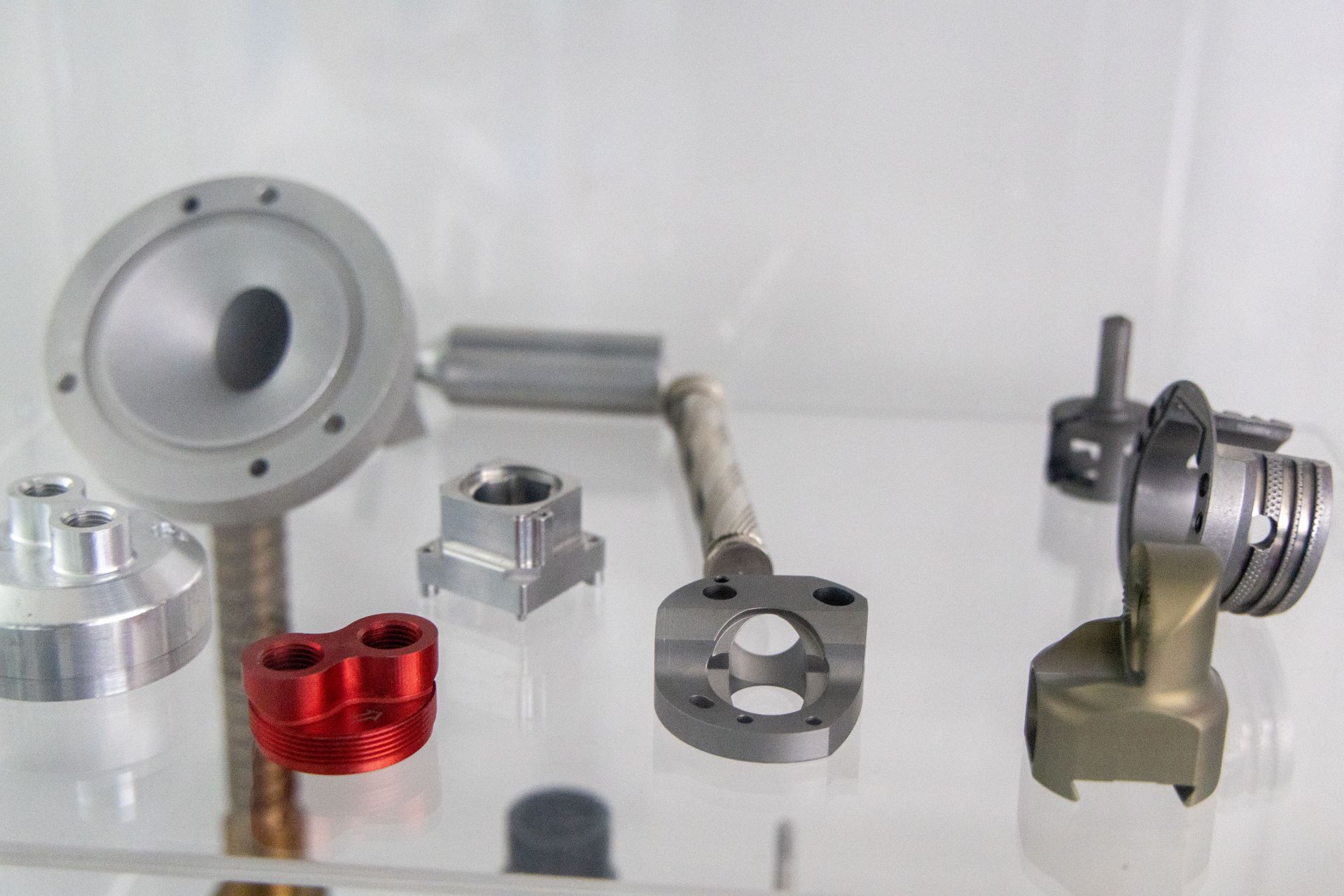

Turning, Milling, Assembly, Production of small metal parts, Marking

|

|---|---|

| Max turning |

Ø from 3 to 65 mm, with bars 3 and 4 meters long

|

| Max milling |

pieces from Ø 50 mm to 1000 mm in milling

|

| Services |

Testing, Technical drawing, Industrial washing, CAD 3D & CAM design, Rapid prototyping, dimensional surveys

|

| Other processes |

Anodizing, Burnishing, Tumbling, Chroming, Lapping, Polishing, Marking, Sandblasting, Hardening, Galvanic treatments

|

| Operating sectors |

Food, Ventilation, Furnishings, Equipment, Automotive, Other sectors

|

| Work area | 840 m² |

| Employees | 16 |

| Metals/Materials |

Steel, special steel, aluminum and alloys, bronze, iron, brass, copper, titanium, special metals

|

| Favorite lots |

Small series, large lots, periodic series

|

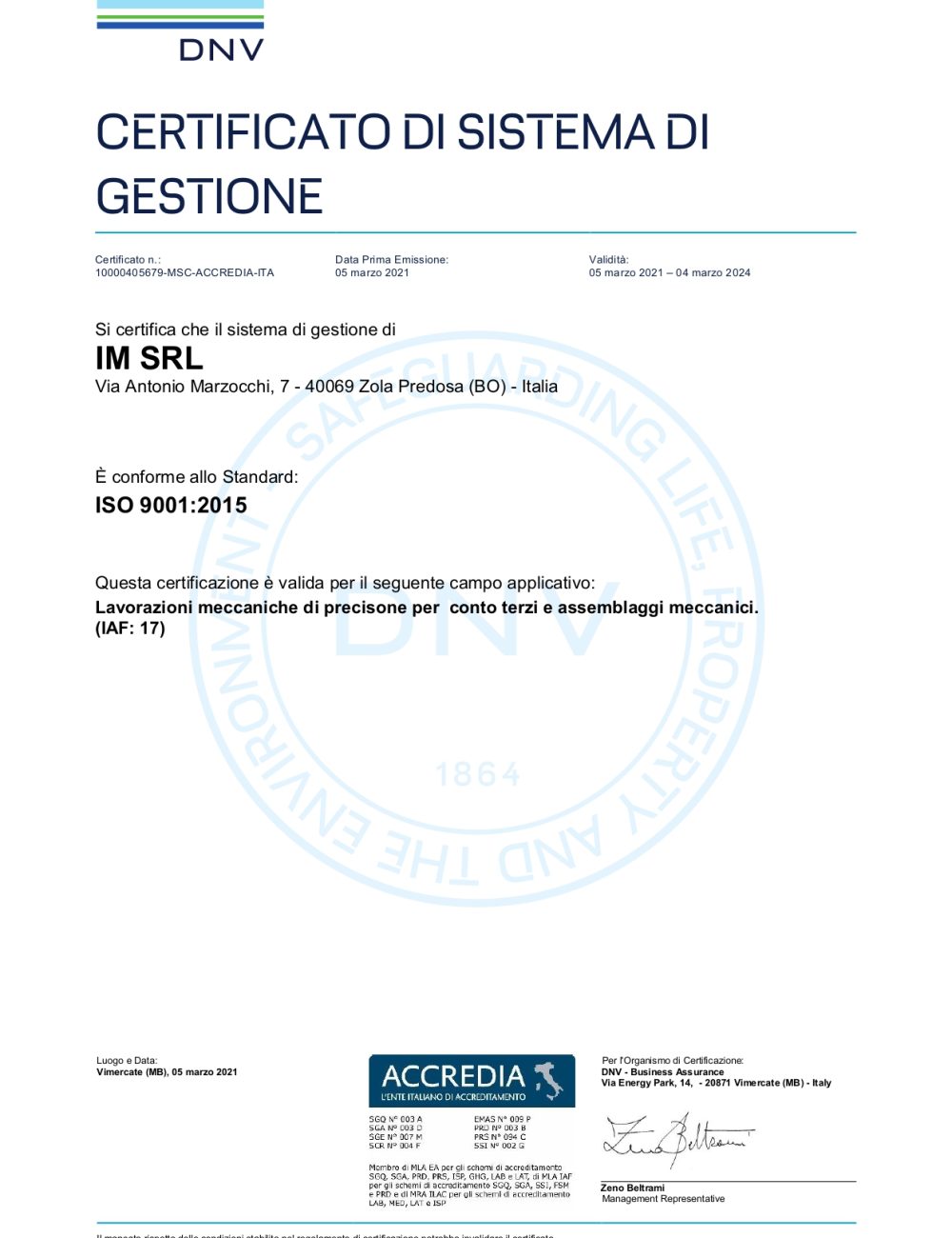

| Certifications |

UNI EN ISO 9001: 2015

|

IM Torneria has been operating in the engineering sector since 1981, collaborating with international companies in the civil and industrial automation sectors, in facilitated pneumatic pruning systems, in the transmission and automotive sector, in pneumatics in general and in fittings.

We are specialized in third-party work on drawings and, thanks to a consolidated experience in the engineering field, we are able to guarantee the quality of the work.

We have been operating in the new factory in Zola Predosa since 2003, where we have expanded our production department and hired new qualified personnel who have allowed our company to grow steadily and progressively. In the same year we started our exclusive production of CBA rigid tapping and boring collets.

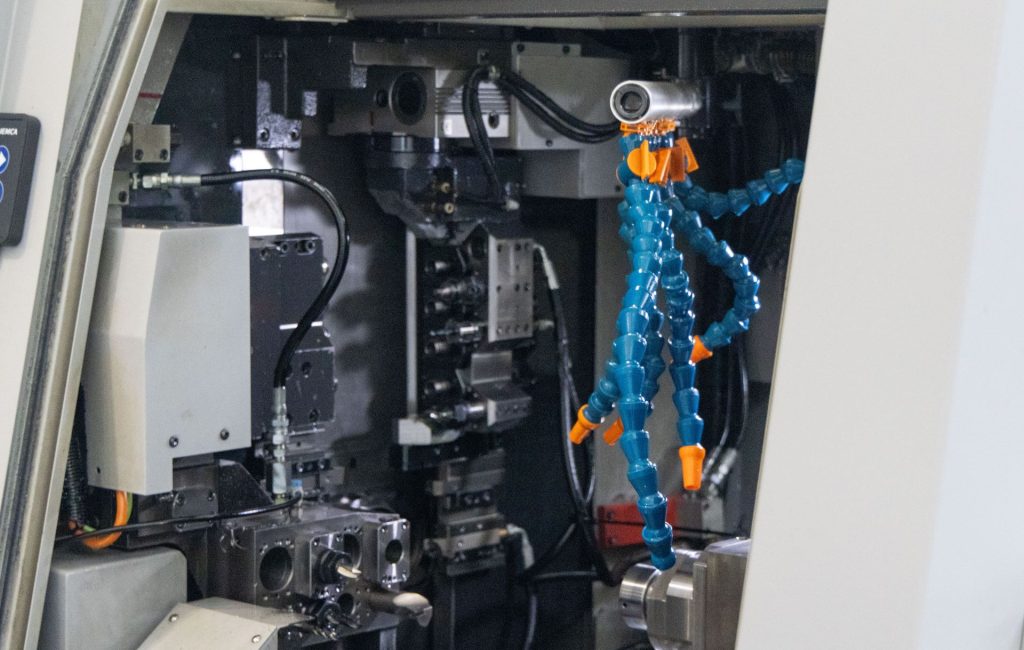

Starting from the bar, both solid and drawn tube, we create your parts in the production department where, depending on the complexity of the part, it can be made on traditional cam lathes or on the most advanced computerized numerical controls with fixed or sliding head .

We work all materials available in bars, from low-alloy to high-alloy steels, and all families of aluminum, yellow alloys, copper, bronze, plastics (PTFE, DELRIN, PVC, PLEXIGLASS, BAKELITE, ETC.)

The details that require further processing are completed in the reworking department where they can be drilled, threaded with or without boss, milled, straightened using a straightening bench, assembled together with others by interference using a pneumatic press, or simply thoroughly degreased or degreased and protected against external agents by our closed circuit washing system.

Our machine park, equipped with automatic turning machines, allows us today to be able to go from a bar passage with a diameter of 3 up to 65 mm, with bars of 3 and 4 meters in length.

The details that require further processing are completed in the recovery department where they can be milled, drilled, threaded with or without boss, straightened using a straightening bench.

We also carry out the assembly of parts that are assembled together with others, by interference, by means of a pneumatic press.

Starting from the bar, both solid and drawn tube, we produce small metal parts on traditional cam lathes, or on the most advanced computerized numerical controls with fixed head or sliding head.

We perform 100% on-demand inspection and CPK paper inspection, and by laser marking we can manage product availability/traceability.

IM Torneria performs the following treatments:

anodizing, bluing, tumbling, chroming, lapping, polishing, marking, sandblasting, hardening and galvanizing

WHY CHOOSE US?

All our processes are performed with modern technologies and are conducted following tested and safe operating protocols. The guarantee arises from the technical management skills of the men employed, oriented towards the highest quality standards and full customer satisfaction.

We carry out the final testing of the components using a highly technological and up-to-date measuring instrument park, including the classic instruments (profilemeter, altimeter, CMM) up to the latest optical instruments with 3 controlled axes including contact probes and spindle for turned shafts.

We are specialized in the creation of third-party work on drawings and we are able to create products that can always respond adequately to the customer's needs, also thanks to the constant search for innovative and modern solutions.

All the components we produce are washed by industrial washing machine with modified alcohol and ultrasonic washing.

We are able to offer assistance in the optimization phase of projects supplied by the customer, but we also carry out 3D CAD & CAM design from scratch. To date, we use Solidworks as CAD, and Esprit as CAM.

We can perform prototyping using Zortrax wire deposition machines, with the possibility of a double nozzle for printing with soluble support for the most complicated geometries.

Thanks to the use of cutting-edge technologies, we are also able to carry out dimensional surveys.

From 01.01.2021 we can create quotes even faster if there send a 3D model. Your 3D model is your advantage, because you will receive estimates faster and we can adjust the prices in your favor.

We have a highly technological fleet of machines, with CNC production machinery, with a high endowment of motorized tools and suitable for continuous 5-axis machining.

We use the most advanced computerized numerical controls with fixed head or sliding head, and our fleet of machines allows us today to be able to go from a bar passage with a diameter of 3 up to 65 mm.

The guarantee of our processes is the result of the technical management skills of the operators employed, oriented towards the highest quality standards and full customer satisfaction.

The work process is managed solely by a single software, this allows us to constantly have everything under control, from order receipt to invoicing, without neglecting the management of the NC and of the entire production cycle in its work phases.

IM Torneria complies with the UNI EN ISO 9001:2015 standard which certifies the company's ability to maintain optimal operating efficiency, reduce defects in the design phase, and constantly seek excellence.