| Top machining |

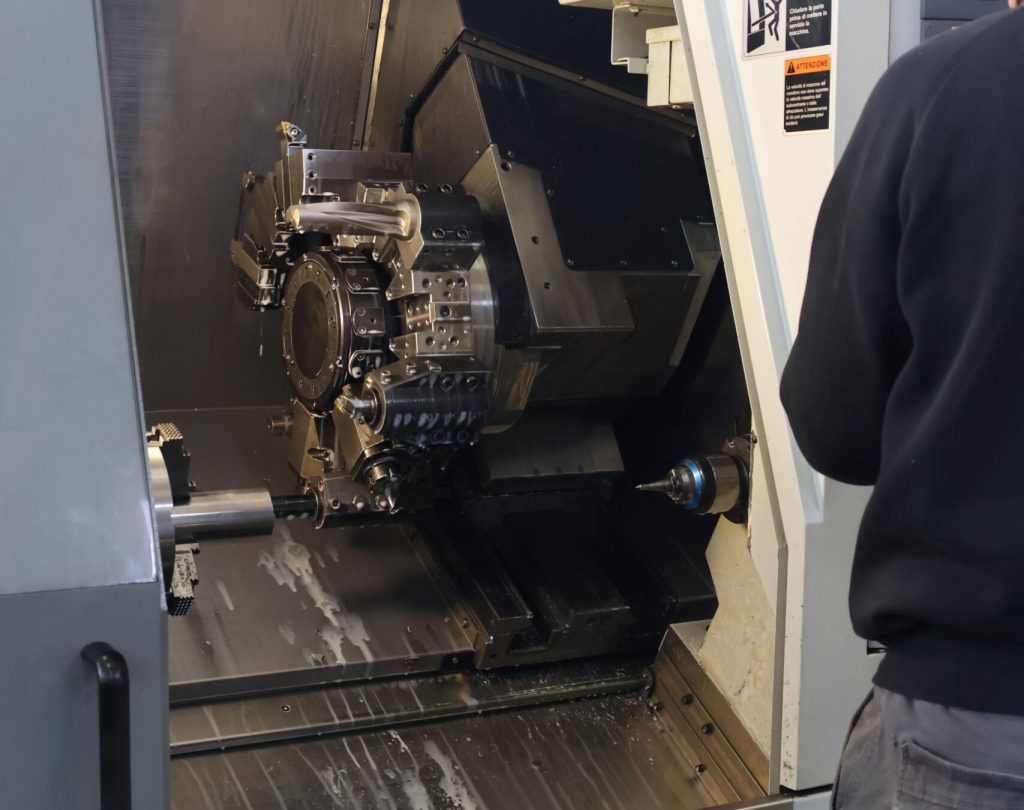

Milling, Turning, Prototyping, Adjusting, Broaching, Mold construction, Marking, EDM microdrilling, Shaping, Surface treatments

|

|---|---|

| MAX. turning |

Ø400

|

| MAX. milling |

X=1500mm Y=600mm

|

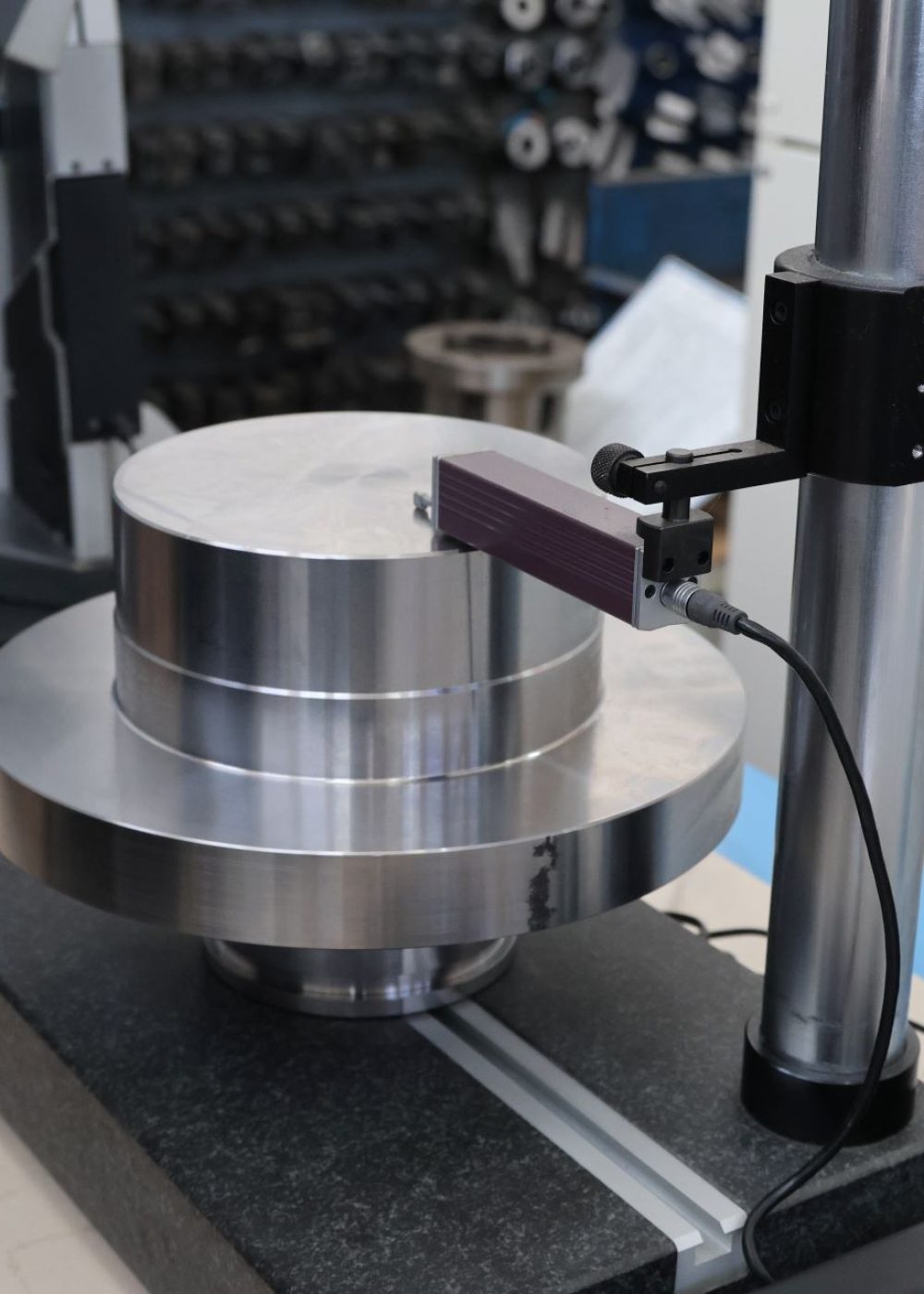

| Services |

Maintenance, supply of spare parts, testing, 3D CAD & CAM design, rapid prototyping, prototypes, replication of advanced parts, dimensional surveys

|

| Operating sectors |

Technology, Lifting of people and goods, Handling, Drilling, Agriculture, Food, Packaging, Filtration systems, Other sectors...

|

| Work area | 500 m² |

| Employees | 11 |

| Metals/Materials |

Steels, special steels, aluminium, aluminum alloys, bronze, iron, cast iron, brass, copper, titanium, special metals, plastic materials

|

| Favorite lots |

Single piece, small series, large lots, periodical series

|

| Certifications |

UNI EN ISO 9001: 2015

|

FADO WORK was born in 2001 from the idea of Luciano Fagioli to create his own new reality in the mechanical processing sector, where he had gained over 10 years of experience.

FADO WORK has specialized over time in customized mechanical components for large and small companies, from design to production.

The experience gained in recent years has allowed the company to grow and become an important point of reference for its customers. The objective is to transfer one's skills to create a group of specialists who can find any type of solution to the needs of the market.

Drive roller in AISI 304 stainless steel, made on a Puma 3100Y lathe

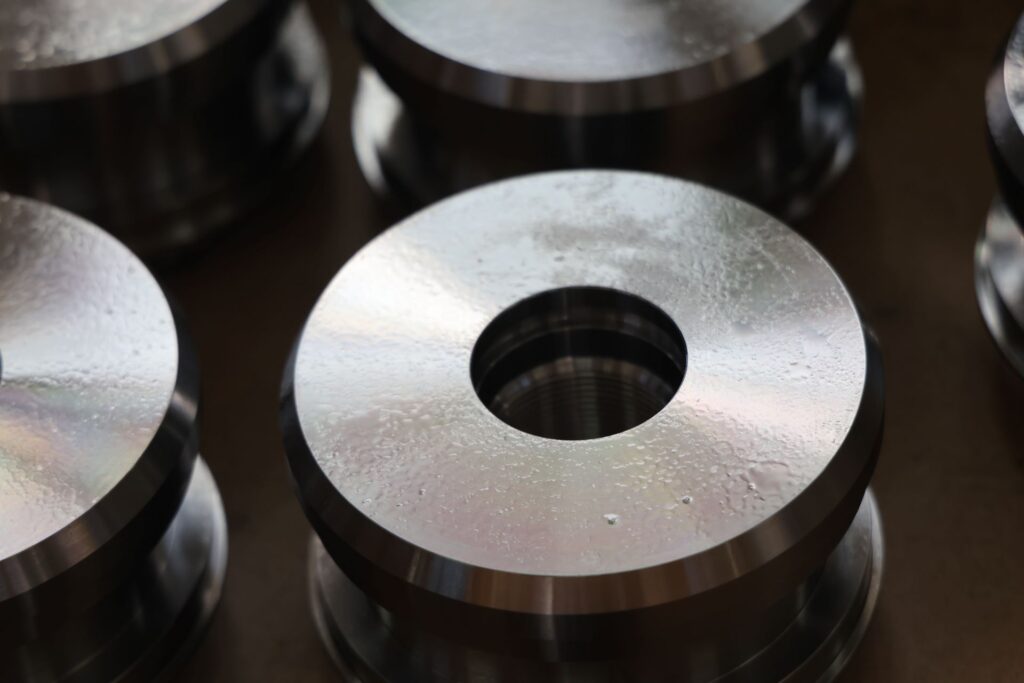

Mechanical detail made on an OKUMA lathe

Hydraulic detail in S355J0, machined on OKUMA 15 lathe

Hydraulic end cap in S355J2, machined on Robodrill in automation with Auriga

Detail in AISI304 stainless steel, machined on a CMZ lathe

Connection in ERGAL 7075 with hard oxidation treatment - Fado Work

Mechanical detail in S355J2, machined and finished on a Puma 3100Y lathe

Roller in AISI 304 stainless steel, made on an OKUMA LB300 lathe

Detail in polyethylene, machined on a CMZ lathe

Our expertise in milling processes allows us to process moulds, metal carpentry, pieces of both small and medium dimensions, with a maximum capacity of X=1500mm and Y=600mm.

Our machine park equipped with various numerically controlled lathes allows us to carry out turning operations for a maximum diameter of Ø400.

We specialize in the machining of small parts via secondary turning, but we also manage the production of medium-sized parts and offer the option of Y-axis machining.

We are also able to manage requests for anodizing, burnishing, tumbling, chrome plating, polishing, marking, sandblasting, superfinishing, hardening, thermal wire spray, painting and galvanic galvanization of specific components.

To provide the customer with the finished order, we also carry out adjustment, broaching, mold construction, marking, EDM micro-drilling, slotting, also making use of external suppliers and partners.

WHY CHOOSE US?

FADO WORK is a young, dynamic and flexible company, with a motivated, highly qualified and independent team, ready to satisfy every customer need.

Our goal is to grow on the market, constantly developing the Know-how necessary to be a competitive company, seeking innovative solutions and processes to provide high quality and timely services to our customers, taking care of relationships with consistency and seriousness.

We have achieved ISO 9001 Certification to consolidate our management system, and thus guarantee customers transparent traceability of processes and uniformity of terminology at a national and international level.