| Top machining |

Turning, Milling, Carpentry, Sheet Metal Cutting, Assembly

|

|---|---|

| Max turning |

Turning ø480 mm

|

| Max milling |

Milling 550x550

|

| Other processes |

Laser Cutting, Punching, Assembly

|

| Operating sectors |

Cleanrooms, Building, Construction, Electrical - Electronic, Energy, Pharmaceutical, Railway, Plant Engineering, Logistics, Ceramic Industry, Racing, Textile, Other sectors

|

| Production area | 5850 m² |

| Employees | 77 |

| Metals/Materials |

Steel, Special Steel, Aluminium, Aluminum alloys, Bronze, Iron, Brass, Copper, Titanium

|

| Favorite lots |

Small or medium pieces, small series, large lots, periodic series

|

| Certifications |

ISO 9001 / UNI EN ISO 3834 / UNI EN ISO 1090 / UNI EN 15085

|

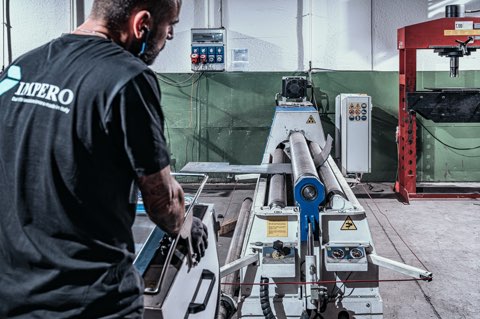

Impero srl is an avant-garde, solid and recognized company in the area, which for over 40 years has been operating successfully in the medium/light carpentry sector for third parties, sheet metal and tube processing, as well as performing assembly and welding on various materials, such as iron, stainless steel and aluminum.

We support our customers in every step: from co-design to the realization of samples e pre seriesand at our surface treatments al quality check, from mounting up to . within the factories.

We have behind us decades of experience in the field of laser cutting of sheet metal, which translate to thousands of pieces studied, developed and implemented custom-made for our customers.

We work for countless sectors – such as the automotive, the ceramic industry, the railway – for companies of all sizes, offering sartorial solutions able to answer specific needs of our customers.

We at Empire are specialized in Laser tube cutting, for this reason we have dedicated a specific division – Empire LT – to this activity. We can make:

round tube - square tube - rectangular tube - flat - oval tube - angles - L profile - U profile

Our workings of custom punching they represent a valid alternative to laser cutting especially when you need to produce large quantities of pieces.

We have special dies and knives that allow us to offer you different types of folding of sheet metal:

Pressed folds – Folds with varying degrees of angle – Rollbend for minimum side lengths – Shapes and holes near the fold line – Z-folds – Radius corners

We specialize in classic calendering, cylindrical shape e conical, but also of shapes more like shaped calendering ovoid.

Over the years we have developed a know-how unique, which makes incomparable our milling and turning services.

Thanks to the presence of advanced machine tools, we are able to offer high quality milling and turning services.

Thanks to the qualifications and many years of experience of our technicians, we can support you in assemblies with MIG/MAG welding e TIG for iron, stainless steel, aluminum and other materials.

We support companies in the creation of customized processes with our co-design service to identify the most suitable carpentry methods, technologies and processes to reduce costs, facilitate processing, eliminate any deformations.

We support you in the creation of customized projects, creating customized samples and pre-series. To guarantee maximum safety, even in large volumes!

Upon request, you can entrust the assembly of your components – also accompanied by their accessories – by our qualified technicians.

We carry out multiple types of checks, such as checking on pieces and specific checks specifically designed for your sector: visual check, dimensional check, with penetrating liquid for welding and many others.

We take care of the last steps for you, such as surface treatments such as galvanizing, painting, anodizing, cataphoresis and burnishing.

Forget about delays and optimize your warehouse management thanks to our packaging and delivery service. Our fleet of vehicles with various capacities allows us to make targeted and scheduled deliveries.

WHY CHOOSE US?

Because Impero srl has existed for more than 40 years: we have studied innovative tools for our customers aimed at reducing costs and improving productivity in companies. Our strength is in the completeness of internal processes and in the adequate service that we can offer.

Our goal is to provide our customers with all the necessary design and technological support, at every stage of the work, to achieve the pre-set results. Experience and craftsmanship are the founding values of our work.

DMG MORI CLX 550 UNIVERSAL LATHE

Specifications:

DMG MORI M1 PRO VERTICAL MILLING MILL

Specifications:

AMADA FIBER LASER ENSIS 3015 AJ 9 KW

Specifications:Served as a double tower warehouse

Working range: 3000X1500cm

MAXIMUM CUT THICKNESS

Iron: 25mm

Stainless steel: 25mm

Aluminum: 25mm

Brass: 18mm

Copper: 12mm

Titanium: 15mm

AMADA FIBER LASER ENSIS 3015 AJ 3 KW

Specifications: Served as a double tower warehouse

Working range: 3000X1500cm

MAXIMUM CUT THICKNESS

Iron: 25mm

Stainless steel: 15mm

Aluminum: 12mm

Brass: 8mm

Copper: 6mm

Titanium: 5mm

LASERTUBE LT7

Specifications:

WORKABLE ROUND TUBE: min. Ø12mm – max. Ø152,4mm

WORKABLE SQUARE TUBE: max. 152,4 x 152,4mm

MAX LENGTH: up to 8500 mm MAXIMUM LINEAR WEIGHT: 23 kg/m

MAXIMUM CUT THICKNESS

Iron: 12mm

Stainless steel: 6mm

Aluminum: 6mm

Brass: 6mm

Copper: 4mm

Titanium: 4mm

MINIMUM WASTE: 105 mm from the end of the last geometry machined

MAXIMUM AUTOMATIC UNLOADING LENGTH: 6500 mm

AMADA HG 2204 CNC BENDING MACHINE

Specifications:

TRUMPF 5230 235 BENDING MACHINE

Specifications:

TRUMPF 5085 BENDING MACHINE

Specifications:

TRUMPF TRUBEND 7036 BENDING MACHINE

Specifications:

Specifications:

PUNCHING MACHINE AMADA VIPROS 358 QUEEN

Specifications:

CALENDER MG 4 ROLLS

Specifications: this tool stands out for the 4 rollers with parallel axes, the ability to work lengths of 2000 mm up to thicknesses of 6mm and the possibility of programming pieces of different shapes

We are forming a team of people who share determination and reciprocity, people who know how to work together and who always find the energy and courage to achieve their goals, transforming them into important results.

The company is certified ISO 9001. and is in possession of a manual of Quality and written procedures for the Process Control and Product. If required, it is available to provide production control documentation and Certificates of Conformity.

We have instruments for evidence, control e test: calipers, thickness gauges, goniometers, bore gauge, roughness gauge, micrometer, set squares, magnetic yoke and penetrating liquids.