| Top machining |

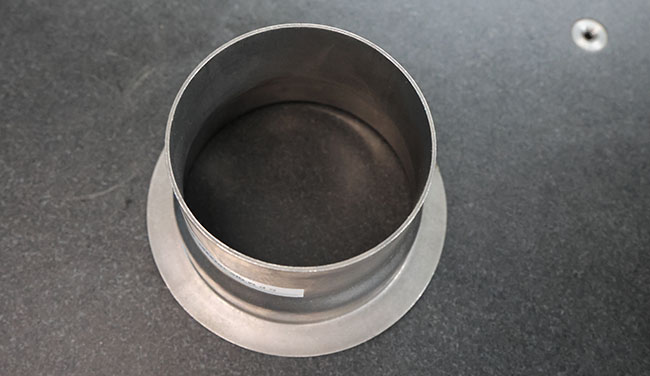

Cutting, Laser cutting, Sheet metal laser cutting, Tube laser cutting, Sheet metal cutting, Tube cutting

|

|---|---|

| Other Processes |

Cold drawing of tubes, tumbling

|

| Services |

Engineering, CAD Programming

|

| Operating sectors |

Automotive, Construction, Hose industry, Naval, Racing, Fluid transport, Other sectors...

|

| Work area | 2500 m² |

| Employees | 17 |

| Metals/Materials |

Steel, stainless steel, iron

|

| Favorite lots |

Small series, periodic series

|

| Certifications |

ISO 9001: 2015

|

CPM SRL prefers to work with companies with at least 50 employees and above, the ideal order is one with medium batches that can be repeated monthly. Currently our production is mainly focused on the production of parts obtained from tubes to supply the flexible hose industry.

Even though it started only for the automotive sector, over the years CPM has diversified its production by including naval, fluid transport and construction, with both medium-high and niche productions (production of special components for motorbikes for Africa Race) .

For more information on parts and processes, contact CPM SRL

For more information on parts and processes, contact CPM SRL

For more information on parts and processes, contact CPM SRL

For more information on parts and processes, contact CPM SRL

For more information on parts and processes, contact CPM SRL

For more information on parts and processes, contact CPM SRL

For more information on parts and processes, contact CPM SRL

For more information on parts and processes, contact CPM SRL

For more information on parts and processes, contact CPM SRL

The CPM SRL company has 4 "Lasertubo" systems that allow processing that was unthinkable on tubes until a few years ago.

Lasertubo systems consolidate several operations into a single work cycle, while the fixed costs generated by punches, vices, masks are eliminated by CAD programming and the laser beam.

The experience in laser technology has led us to implement our machine park with machinery dedicated to laser cutting of sheet metal which, in integration with laser tubes, has also allowed us to create products for the construction industry.

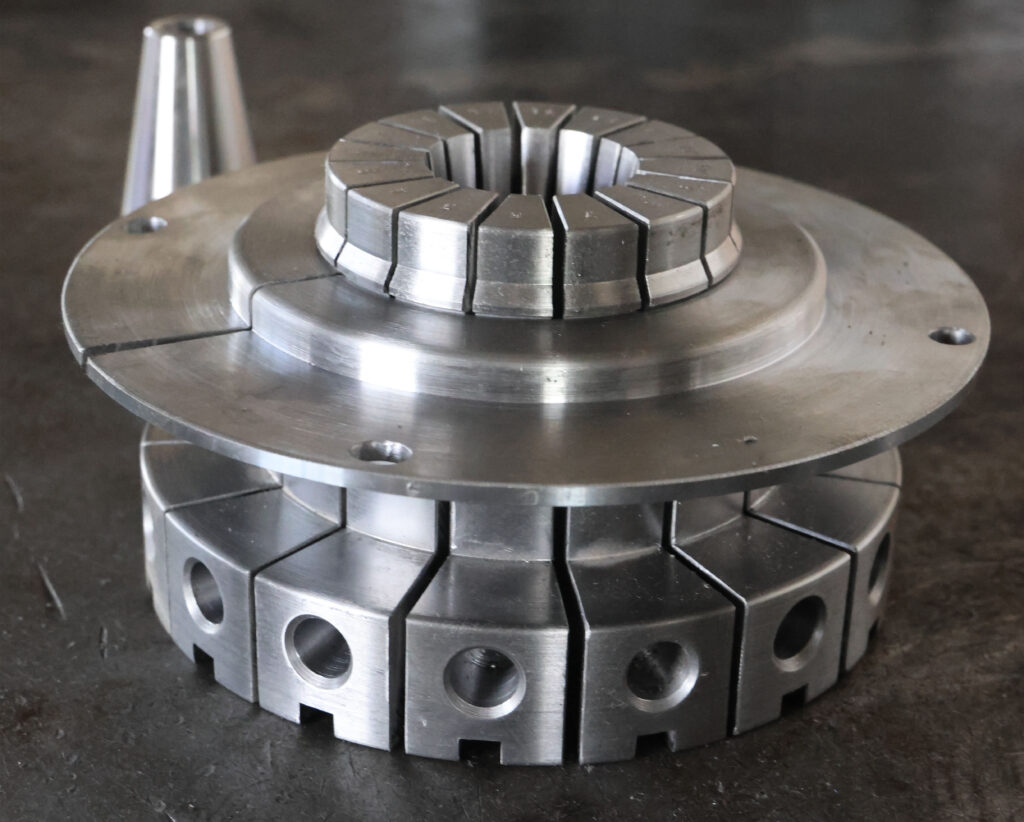

In addition to the various systems for tube deformation, CPM SRL has a tooling department for the construction of moulds.

WHY CHOOSE US?

CPM SRL is currently ISO 9001:2015 certified, has around twenty employees, has an excellent rating and ownership of the property, has a pipe warehouse with an average stock of 400 bundles in continuous rotation, 6 laser systems, mechanical presses and hydraulic systems, disc tube cutters, vibration systems for cleaning the pieces, a tooling department for mold construction and system maintenance which makes it autonomous in the event of failures.

All this combined with over thirty years of experience make CPM a "safe" partner.

La CPM SRL eliminates traditional fixed costs generated by punches, vices, jigs thanks to the service CAD programming and the laser beam. It also accomplishes engineering on components made from tubes.

The potential of Lasertubo systems is infinite: they consolidate different operations in a single work cycle, while the traditional fixed costs generated by punches, vices, masks are eliminated by CAD programming and the laser beam.

Various types of tube cutting and deformation are used, ranging from automatic sawing machines to 4 Lasertubo systems: the synergy between the Lasertubo combined with the cold deformation systems allows for the creation of an almost unlimited number of types of products obtained from bar tube.

In addition to various systems for tube deformation and a tooling department for mold construction, the company has 4 "Lasertubo" systems which allow processing that was unthinkable on tubes until a few years ago.

CPM SRL has a metrology room with a Hexagon three-dimensional measurement system as well as calipers, control pads and projectors.

CPM SRL has obtained ISO 9001 2015 certification.

All the processes indicated for the management and maintenance of the ISO 9001 2015 certification are adopted by our company.