| Top machining |

Turning, Milling

|

|---|---|

| MAX. turning |

1000 mm

|

| MAX. milling |

2000x4000

|

| MAX. toothing |

1000 mm

|

| Other processes |

Broaching, wire EDM, grinding, shaping, surface treatments, toothing

|

| Services |

Testing, Technical Drawing, Dimensional surveys

|

| Operating sectors |

Agricultural, Food, Automotive, Energy, Wind, Railway, Industrial Machinery, Other sectors...

|

| Production area | 50000 m² |

| Employees | 120 |

| Metals/Materials |

Steels, special steels, aluminium, aluminum alloys, iron, cast iron

|

| Favorite lots |

Small series, large batches

|

| Certifications |

UNI EN ISO9001 / ISO TS 16949 / Other

|

It was 1952 when Silvio Chiaravalli began to realize his dream of "building mechanisms to help man in his daily life" on the slopes of the Lombardy Alps.

70 years have passed today and its legacy is a global multi-sector group built on solid foundations laid in the post-World War II Italian context.

The Chiaravalli Group today is structured into four commercial divisions covering Industrial, OEM, Food and Motorcycle.

Chiaravalli Group is a unique synthesis of Passion, Expertise and Tradition.

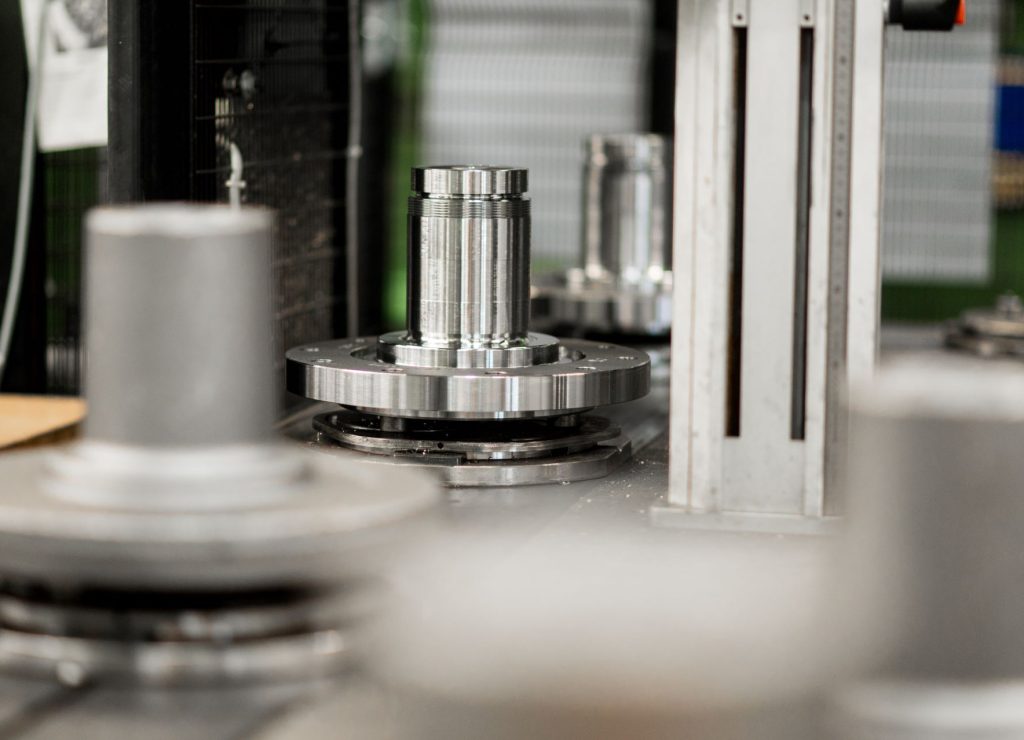

With the sole aim of supporting our customers with an ever-evolving offering, we use modern technologies and machinery to provide high-quality turning processes.

Thanks to the use of CNC machinery, we are able to provide quality milling processes, compliant with the precision requirements of our customers' projects.

We have 7 broaching systems that allow us to safely and precisely produce components intended for different industrial sectors.

Our products are the result of careful processing, to be able to operate with maximum efficiency even under high load conditions.

We have the most advanced technologies in grinding, blanking, turning, induction hardening, cleaning and sharpening operations.

Our staff, thanks to great experience and specific know-how, works to produce top quality components.

Thanks to a limited selection of partners, we are able to offer a complete service, in addition to mechanical processing such as:

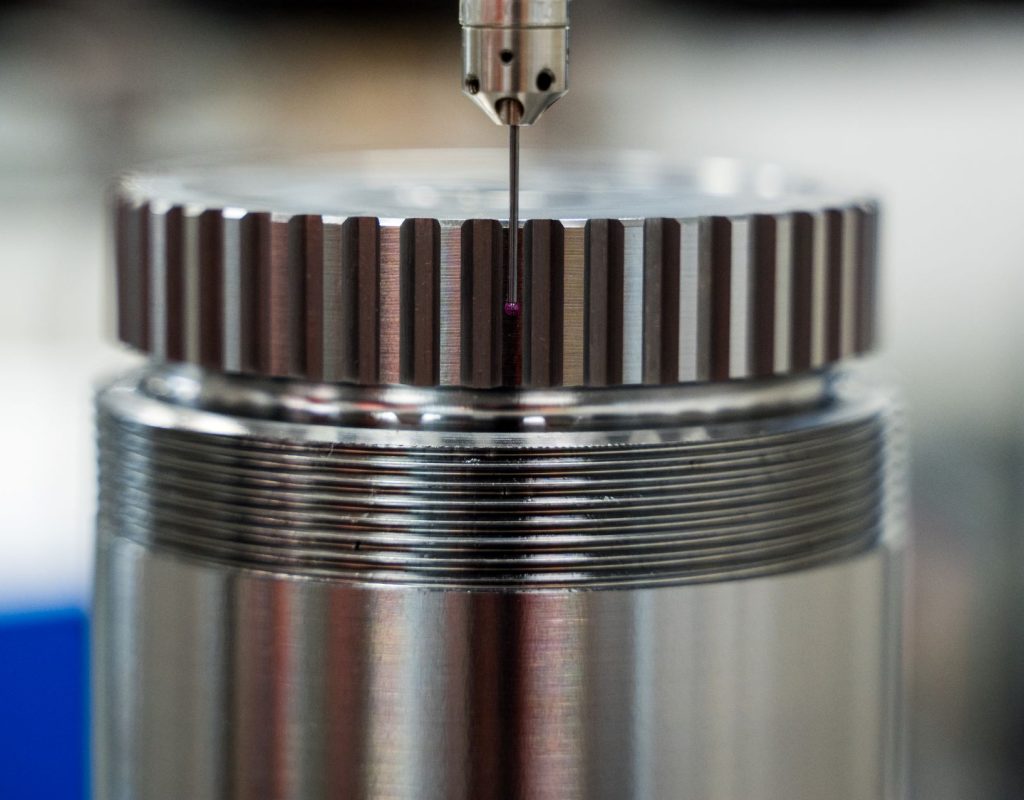

Our commitment to tooth-for-tooth profile optimization results in smoother gearing and balanced load transfer.

Made with computerized precision tools and state-of-the-art manufacturing methods, our spur gears are suitable for a wide variety of industrial applications and are guaranteed to have a long operating life.

WHY CHOOSE US?

The roots of Chiaravalli Group lie in Italian production history.

Today, thanks to the OEM division, we combine the passion of our DNA with the innovation and solidity of an international group. We design and manufacture high-precision mechanical components for world-famous manufacturers in the most varied sectors.

We have more than 300 state-of-the-art CNC machine tools that allow us to work safely and precisely, and produce mechanical components that meet the highest precision requirements of our customers.

We certify the quality of our products through instrumental checks carried out in our 6 meteorological rooms by high-precision automated robots with three-dimensional laser and contact measurement.

Furthermore, the production is controlled step by step with electronic instruments and CLOSED LOOP. Chiaravalli boasts, among others, UNI EN ISO9001 and ISO TS 16949 certifications.

The implementation of the QHSE Policy is guaranteed through:

These allow us to give continuity to the processes with the main objective of streamlining and consolidating the results that have always been obtained.

For us, Quality is a value rather than an objective: to the procedures of constant control and research into processes that meet the highest standards, we combine a meteorological room dedicated to quality control with 7 of the most advanced ZEISS instruments.

The components are checked and measured after each step in order to guarantee constant monitoring of the work carried out on the product.

Chiaravalli boasts, among others, UNI EN ISO9001 and ISO TS 16949 certifications.

More information about our certifications , promising