| Top machining |

Blanking, Assembly, Washing, Testing, Mold construction

|

|---|---|

| Other processes |

Tumbling, Calendering, Carpentry, Threading, Drilling, Drawing, Bending, Welding, Stamping, Cutting, Galvanic plating

|

| Operating sectors |

All metalworking sectors

|

| Work area | 1800 m² |

| Employees | 12 |

| Metals/Materials |

Steel, special steel, aluminum, aluminum alloys, bronze, iron, brass, copper

|

| Favorite lots |

Small series, large lots, periodic series

|

| Certifications |

UNI EN ISO 9001: 2015

|

Trancerie Vicenza Srl is a company specialized in blanking, drawing and stamping of metal alloys.

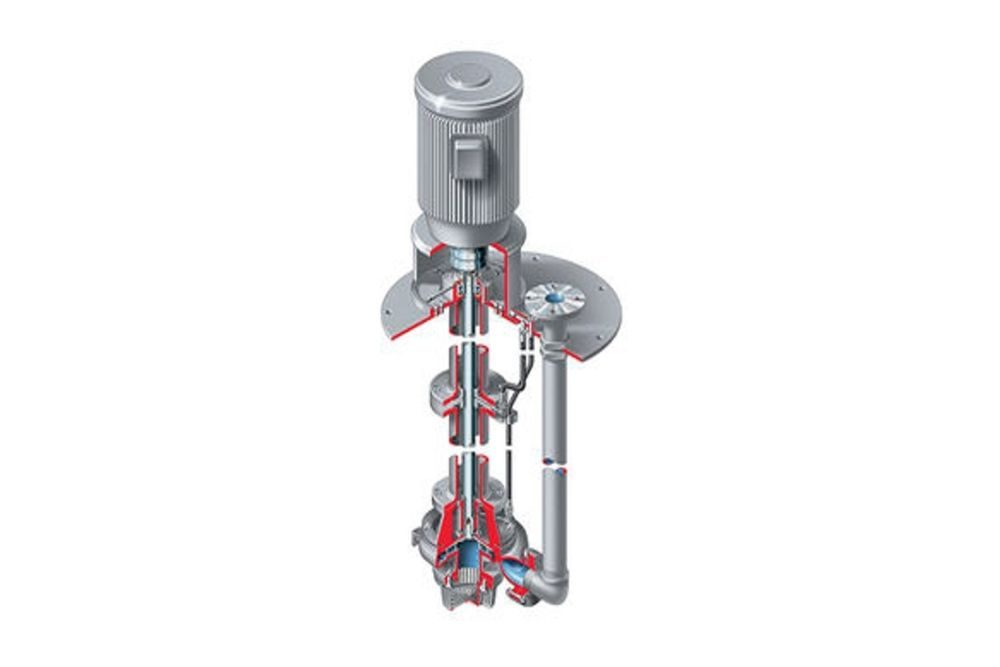

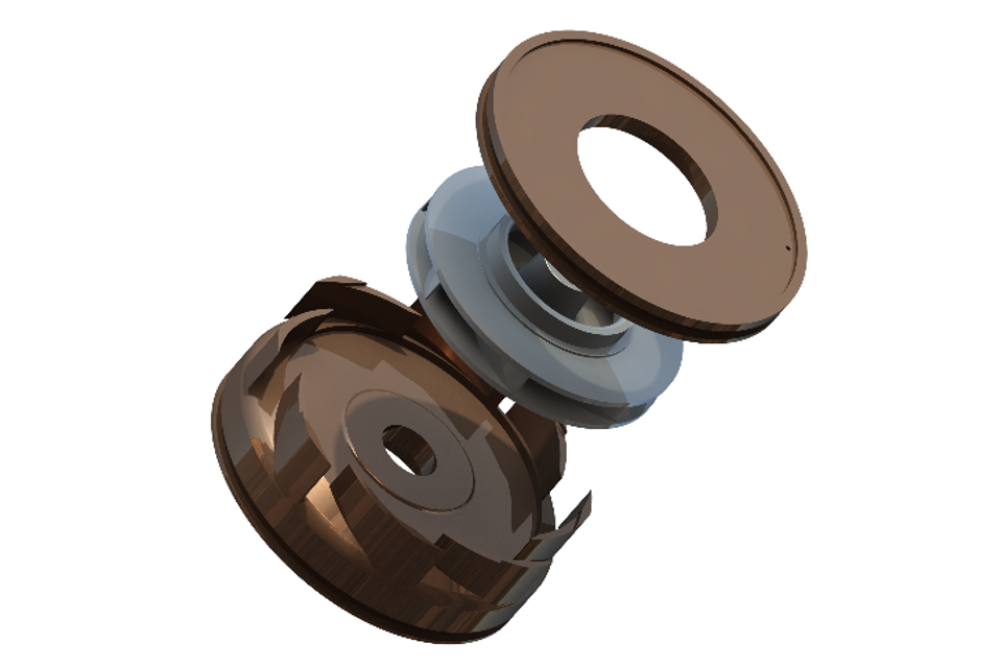

The company produces immersion pumps, ventilation grids, brackets and supports for air conditioners, hinges, components for agricultural machinery, steering wheels for trucks, various components and details for various sectors.

In Trancerie Vicenza we aim to offer a 360 ° service, in order to guarantee quality products, effective services, punctuality and support to our customers. This is because we want to transform collaboration with the customer into a partnership, and be considered a point of reference for any business need.

We specialize in the blanking and molding of all metal alloys starting from strip, strip, drawn or square.

On request, we can take care of assembling mechanical components produced by us or supplied by the customer. We plan specific work cycles and guarantee high quality standards for each realization.

We collaborate with partners equipped with: step-by-step and continuous rotating carousels, sandblasters, tumblers, robotic islands for

grinding and polishing, polishing machines, baths for galvanizing, welding machine e

laser cut.

Thanks to numerous partnerships consolidated over time, we can follow all phases of

processing, from molding to final treatment, checking the entire supply chain up to the realization of the

final product. This allows us to optimize production times and costs, and to provide an excellent all-round service, guaranteeing excellent results

value for money.

We are equipped with a perchlorethylene washing system that allows us to wash and degrease pieces in stainless steel, copper and brass. We also wash FE parts with oiling for rust management. In addition, the plant is equipped with ultrasound.

We have a fleet of machines ranging from 50 to 300 mechanical tons (double

mont. O neck swan) and hydraulic presses that allow us to test the molds.

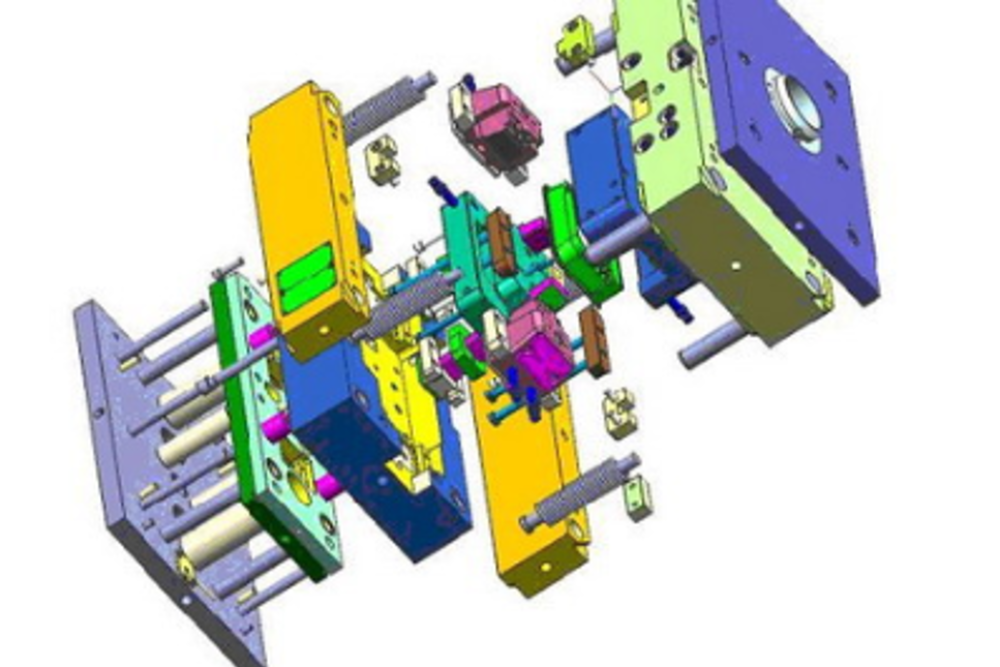

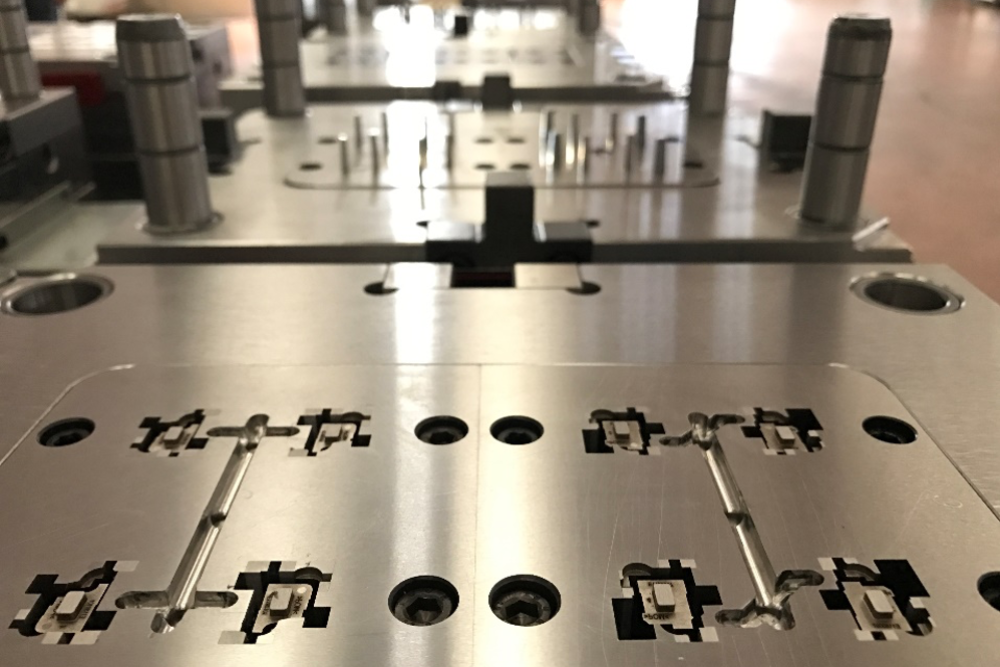

Through our subsidiary we take care of designing and building new molds for the most varied production needs. We supply blanking and drawing dies in any metal alloy, thanks to first-rate machinery and modern design software.

Why choose Trancerie Vicenza?

Quality, punctuality e competitiveness are our strengths.

We operate on large quantities as well as on small numbers, guaranteeing the same dedication to every order.

We work with material both for subcontracting and for direct purchase, to ensure the maximum flexibility to our customers.

We monitor the quality of the semi-finished product along all the phases and again at the end of the cycle, to be sure of offer to our customers the best possible service.

Furthermore, thirty years of experience have led us to develop a particular focus on the sectors of luxury cars, hydraulic pumps and heat machines, but we are always happy to compete with new projects.

We have specialized for more than 20 in the production of components for submersible pumps.

Our company operates in molding by producing aesthetic and non-aesthetic components,

for the automotive sector.

We also deal with the welding of tractor noses, hinges and various components.

We operate in the food sector for the production of pizza spatulas, ice cream scoops and kitchen tools.

Our company prints components for kitchens such as trays, hinges, guides, combs for dishwashers, shelf brackets, burners for gas ovens, blades for office chairs etc ...

Furthermore, we carry out molding of hinges for clean rooms.

We take care of washing brass electrical components.

We carry out the molding and deep drawing of steering wheels for trucks and ships.

We produce brackets and collars for the aeration sector.

Machine name: OTI 300 TON

Machine name: Workbench for automotive parts

Machine name: AIDA TRANSFER 250 TON

Machine name: SHIP 1

Machine name: OTI 300 TON / Double upright

Our staff is qualified, motivated and trained to meet your needs.

The company aims to offer a 360 ° service guaranteeing quality products, efficient services, punctuality and support, to become a point of reference and respond effectively to customer requests.

Trancerie Vicenza Srl is certified Q-AID, ISO9001-2015, carries out checks on drawing and on batch breaker.

Trancerie Vicenza srl complies with the requirements of the ISO 9001:2015 standard. In this way you can be certain that the services and products created correspond to certain characteristics and that all the phases relating to their realization can be traced and verifiable.

Our company offers references in the automotive sector, immersion pump sector, ventilation grilles, brackets and supports for air conditioners, hinges, agricultural machinery components, parts for the food sector, steering wheels for trucks and various components.